- Design & Archetype according to your idea

- High-Grade Aluminum Ingot Raw Material

- We accept ODM/OEM custom aluminum tubing

- ISO 14001-2004 and ISO 9001-2008 Authorized Company

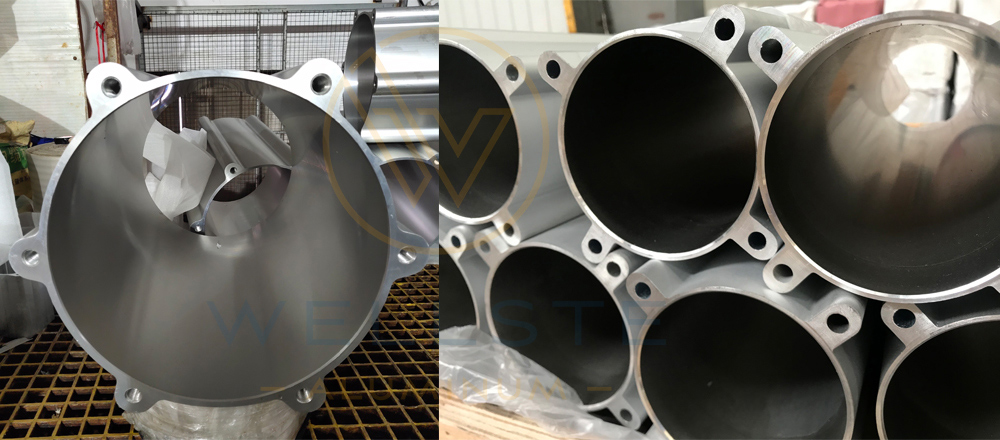

Pneumatic cylinder tube

Wellste Pneumatic Cylinder Tube also known as Aluminum Pneumatic Cylinder Tubing or Aluminum Profile Tube are offered top-quality in Wellste.

These will provide the perfect solution for your Honed Tube requirements.

Innovate One-stop Solution of Pneumatic cylinder tube

Wellste Pneumatic Cylinder Tube is the most suitable foundation for high-quality pneumatic applications.

Pneumatic cylinder tubes in Wellste have internal tolerances of H11 or H12 that stand out due to their extraordinary precision, high levels of dimensional performance, and resulting in the least reworking demands.

Wellste Pneumatic Cylinder Tube designed with super durability against abrasion, accurate dimension, easy handling, light, and corrosion non-magnetic.

These will serve with trouble-free completion in chemical, high moisture, and other unfavorable environments including salt and chlorinated water which occurs in a vital reduction in life cycle costs.

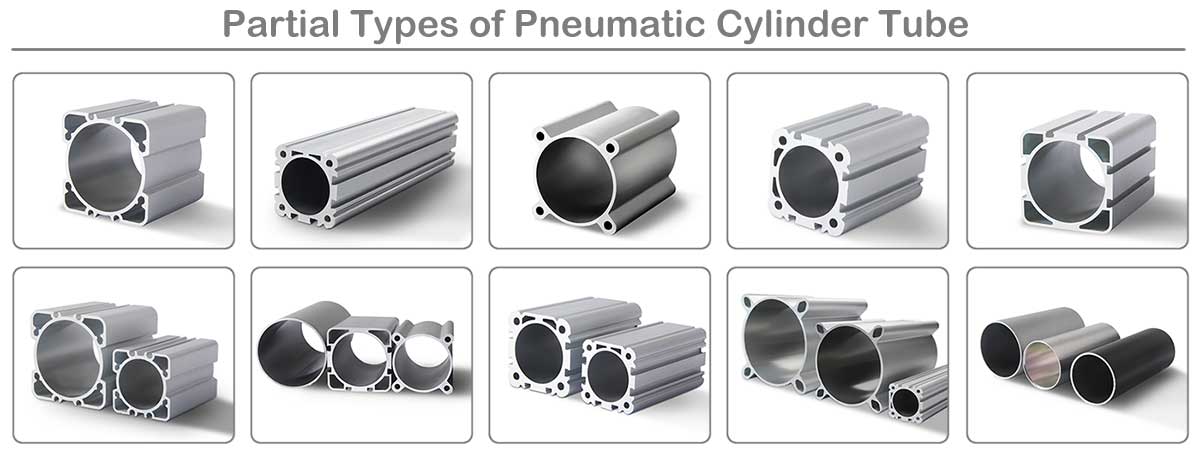

Pneumatic Cylinder Tube in Wellste is available in a range of standard and custom sizes.

These can be particularized with either standard bore measurements or standard wall thicknesses. A wide variety of stock sizes and various finishes are available in Wellste.

| Product Name | Pneumatic Cylinder Tube |

| Material | 6000 Series Aluminum Alloy |

| Temper | T4-T8 |

| Open Mould | 10-15 days |

| Roughness/Straightness | Customize |

| MOQ | 500KG each |

| Quality Standard | GB/T 5237-2008,GB/T 6892-2015, |

| Tolerance EXT. | DIN2391, EN10305, GB/T 1619 |

| Tolerance INT. | H7, H8, H9 |

| Surface Finish | Mill-finish, Anodized, Powder-coated |

| Standard Packaging | Bundle with steel strip and PE sheet or wooden case |

| Deep process | Drilling, CNC, milling ,cutting ,bending ,tapping ,welding ,assembling ,punching |

Contact Wellste now! We will be pleased to personally answer your questions on dimensions, materials, processing possibilities, properties, and availability of Pneumatic Cylinder Tube.

Tight Tolerance Dimensions is according to EN 755 or ANSI H35, Compliance with China Industry Quality Standard

Matt anodizing & hardness Anodizing Support, Ready stock available size for fast delivery to Global Area

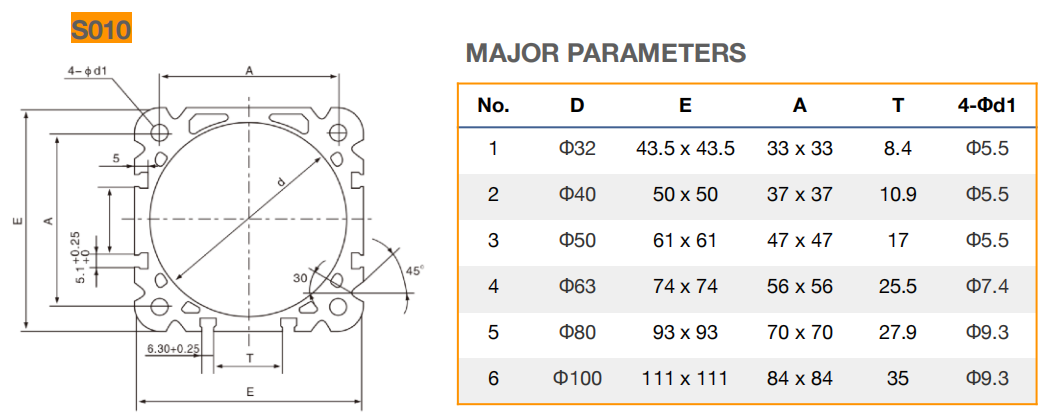

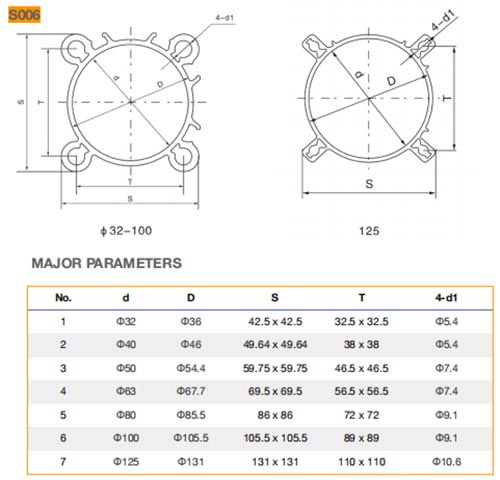

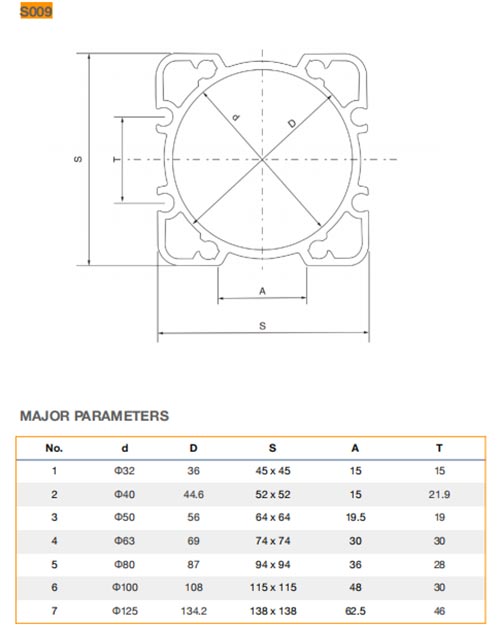

Standard Pneumatic Cylinder Tubing inner size range from φ32 to φ200mm for your select

Honed Cylinder Tube Inner Roughness(Ra) can be less than 0.6, Internal Diameter Tolerance controlled in H11.

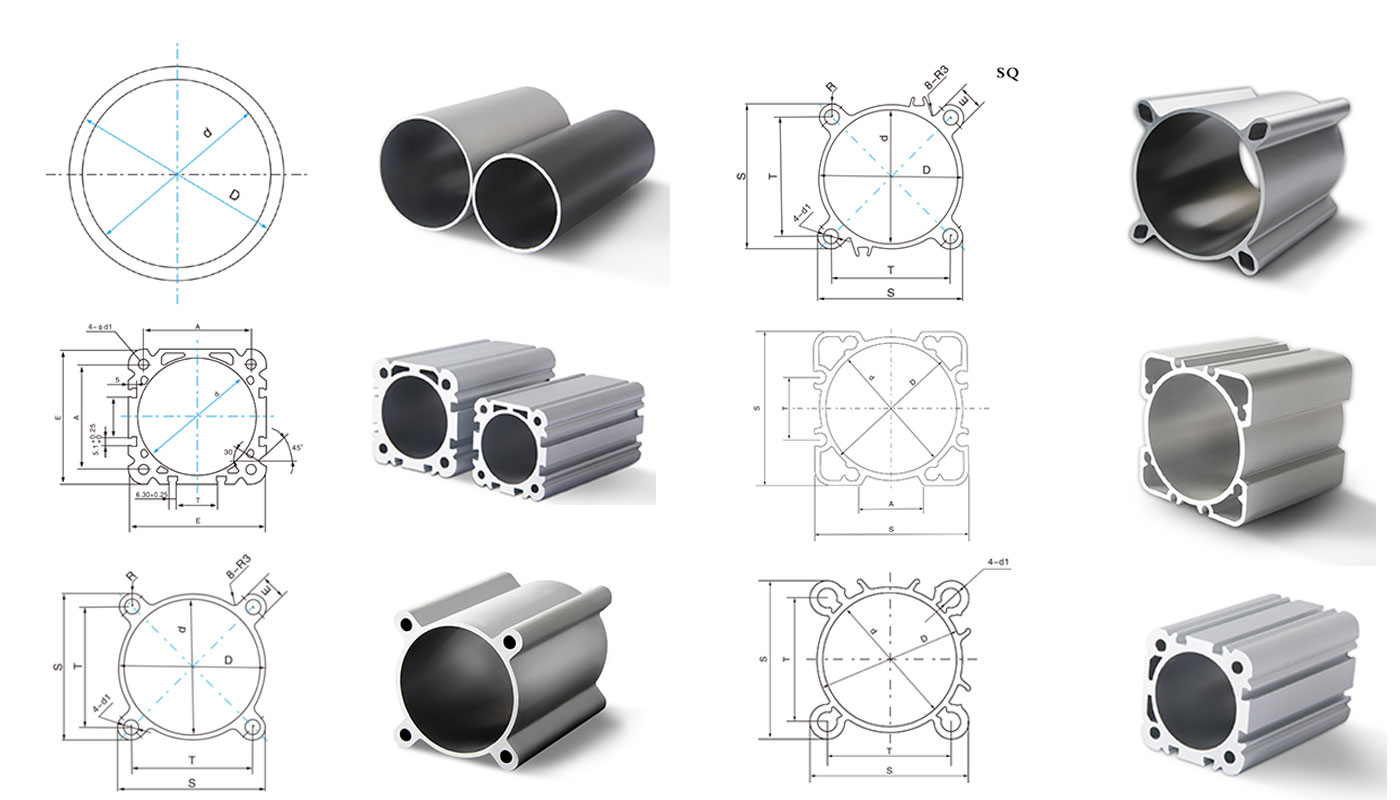

Extruded cylinder tubes are available in various forms such as standard cylinder, mini cylinder, and compact cylinder.

We have a professional team of engineers responsible for your custom aluminum cylinder tube

- Technical Parameters

- Tolerance Data

- Advanced Equipment

* Support custom surface finish and your design

| Bore Size | 16/20/25/32/40/50/63/80/100/125/160/200/250/320mm |

| Material | AA6063 T5 |

| Inner Diameter Tolerance | H9-H11 |

| Strightness Tolerance | ≤1mm/1000mm |

| Surface Roughness | Ra <0.6, OR Ra 0.3 upon your request |

| Anodized Film | ≥15 μm |

| Standard Stock Length | 2.0 – 3.0 meters |

| Oxide Film Hardness | ≥ 400HV |

| Tensile strength | 160 Mpa |

| Yield Strength | 110 Mpa |

|

diameter

|

Tolerance | |||||

| H9 | H10 | H11 | ||||

| 16 |

0

|

+0.043 |

0

|

+0.07 |

0

|

+0.110 |

| 20 | +0.052 | +0.084 | +0.130 | |||

| 25 | +0.052 | +0.084 | +0.130 | |||

| 32 | +0.062 | +0.100 | +0.160 | |||

| 40 | +0.062 | +0.100 | +0.160 | |||

| 50 | +0.062 | +0.100 | +0.160 | |||

| 63 | +0.074 | +0.120 | +0.190 | |||

| 70 | +0.074 | +0.120 | +0.190 | |||

| 80 | +0.074 | +0.120 | +0.190 | |||

| 100 | +0.087 | +0.140 | +0.220 | |||

| 125 | +0.100 | +0.160 | +0.250 | |||

| 160 | +0.100 | +0.160 | +0.250 | |||

| 200 | +0.115 | +0.185 | +0.290 | |||

| 250 | +0.115 | +0.185 | +0.290 | |||

| 320 | +0.140 | +0.230 | +0.360 | |||

Yes, Wellste is able to provide Pneumatic Cylinder Tube for you to check the quality, Normally stock sample is free for saving you cost, But it will require tooling costs if the custom tube size is.

Order amount should be more than USD 2000 with existing stock, Pneumatic Cylinder Tube should be no less than 100 meters of each type.

It is only taking 7-10 days to complete your sample if the sample size is in stock.

For Pneumatic Cylinder Tube, commonly it requires 30-35 days at 1st order since it takes more time on making tooling.

30% TT in advance, and the balance payment is paid before shipment. OR can be discussed if your qty is large.

Sliver Anodizing, Black Anodizing, Sandy Anodizing, Bronze Hard Anodized.

We inspect the product after each manufacturing process and we have advanced test facilities and instruments, We also can supply SGS certification for your reference.

Paper tube and exporting wooden case, or customized requirement.

Why Choose Wellste for Your Pneumatic Cylinder Tube

Wellste: Your Premier Pneumatic Cylinder Tube Manufacturer/Supplier

Wellste can stock high-quality pneumatic cylinder tube products to meet your JIT, MRP, or KANBAN requirements.

Wellste has excellent manufacturing capabilities such as mold design, aluminum ingot casting, extruding press, sandblasting, anodizing, spraying coating, CNC machining services, welding services, and more.

Are you looking for a pneumatic cylinder tube? Here in Wellste, we are specialized in producing a pneumatic cylinder tube.

Wellste Aluminum is a pneumatic cylinder tube company expert with 20+ years of manufacturing experience.

Wellste Pneumatic Cylinder Tube also named Aluminum Pneumatic Cylinder Tubing or Aluminum Profile Tube, are a good choice for any pneumatic application in every industry.

These are manufactured using high-quality components with 5000 series, 6000 series, 7000 series of aluminum tubing. All can be made in Wellste. All glands and pistons are made of aircraft quality 6061 aluminum to reduce weight and prevent corrosion.

Wellste as a Pneumatic Cylinder Tube manufacturer for almost 20 years developed high integrity and professionalism in supplying products to clients. We produce not only pneumatic cylinder tube but also large selections and stocks of Aluminum Round tube, aluminum square tubing, Aluminum rectangular Tubing & aluminum oval tube.

The most popular alloy no. to create a pneumatic cylinder tube is 6061 and 6063. Both of them have excellent corrosion resistance features, wearability, lightweight, and a good standpoint for the anodized pneumatic cylinder tube. Wellste pneumatic cylinder tube is fit for high and low temperatures, as well as areas where grit, grease, chemicals, or salt are present.

Wellste renders several kinds of surface treatment. There are anodized, powder-coated, electrophoresis coating, and PVDF coating. With these properties, the pneumatic cylinder tube has a wide range of applications in a different area.

In China, Wellste becomes popular for manufacturing high-quality pneumatic cylinder tube. For every industry, our pneumatic cylinder tube works superbly. This incredible solution is in-demand in both domestic and foreign businesses. We also offer customized designs for you to choose and decide what you prefer.

There`s a lot of advantages and benefits that the pneumatic cylinder tubes can bring to any applications. Get and purchase yours now to boom your business!

Wellste is committed in the aluminum extrusion industry for about 20+ years. Wellste integrates research, extrusion, design, and deep machining services, such as casting, cutting, CNC machining, stamping, bending, drilling, welding, and more. We are your reliable source of pneumatic cylinder tubes with talented engineers and sales team.

Ask for an instant quote from us!