- Offers high thermal conductivity

- Highly efficient, durable and lightweight

- Highly customizable design with LOW MOQ

- Precision machined for improved heat dissipation

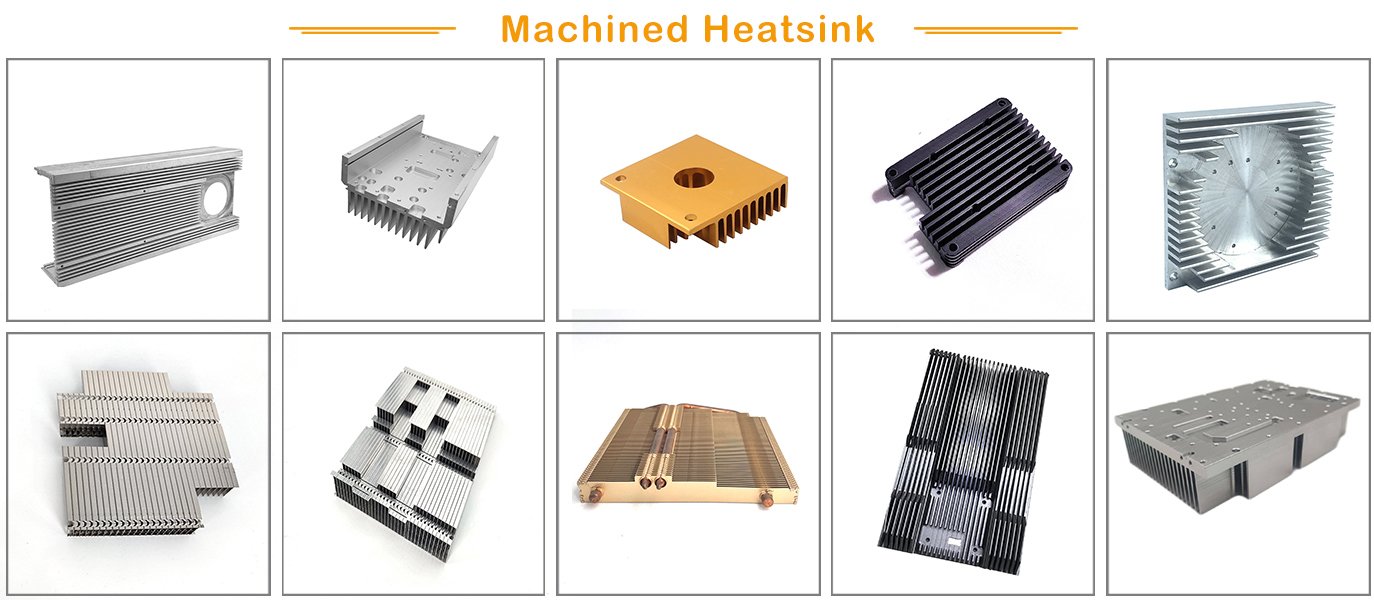

Machined Heatsink

Wellste is professional in custom aluminum extrusions and custom aluminum fabrication.

With deep expertise in custom heat sink manufacturing, we provide a wide range of machined heatsink solutions

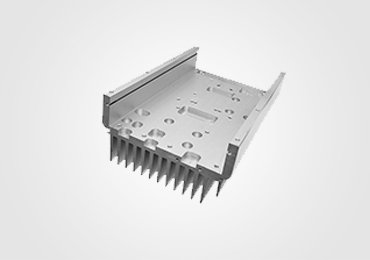

Machined heatsinks involve the removal of material through precision machining. Wellste use machine tools to carry out the mechanical processing of raw materials.

Wellste: The Top Machined Heatsink Manufacturer

Wellste has over 30 sets CNC machines, including drilling, punching, milling, cutting, welding, bending, and tapping machines.

When compared to other extruded heat sink, machined heatsinks offer several advantages.

First, machined heatsinks don’t restrict the material or processing type. They produce through machining, whether using copper or aluminum.

Second, they have high thermal transmission. Machined heatsink material determines its heat transfer performance. Aluminum or copper material can transfer heat from one location to another more quickly.

Wellste machined heatsinks don’t need mold production, leading to savings in tooling costs. And, CNC heatsink offer various machining design options, like milling, punching, tapping, drilling, etc.

| Item Type | Machined Heatsink |

| Material | Aluminum, Copper |

| Size | Standard or customized size |

| Colors | silver, black , blue, wood color, RAL powder coating color, and so on |

| Shape | Round, Square, Flat, or customized |

| Thickness | 0.4mm-20mm or Customized |

| Application | LED Lighting, Inverter, Welding Machine, Communication Device, Power Supply Equipment, Electronic Industry, Thermoelectric Coolers/Generator, IGBT/UPS Cooling Systems, etc. |

| Production Process | Profiles Extruding—Cutting—CNC Machining(Milling, Drilling, Tapping)—Deburring— Cleaning— Inspecting–Packing |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| Deep process | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| Tolerance | ±0.01mm |

| Length | customized length |

| MOQ | Low MOQ |

| Packaging | standard export packaging or as discussed |

| OEM & ODM | Available. our engineer can check and discuss your design, great help! |

| Free Samples | Yes, we can provide free sample |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Port | Shanghai Port |

Wellste manufactures machined heatsinks with high precision. The machining process controls and adjusts through strict settings and tests, resulting in very reliable process.

Wellste machined heatsinks have various applications, such as electronics, appliances, automation equipment, machinery, and LED lighting.

According to the production process, heat sinks include machining, extrusion, die-casting, forging, zipper fins, bonded fins, skived fins, etc.

Machined Heatsinks include milling heatsinks, skived heatsinks, and stamped heatsinks, etc. Material typically made from Aluminum 6061 or Copper C1100.

Wellste machined processing has two types: manual machining and CNC machining.

Manual machining is a manual process by workers, they use machinery like milling machines, lathes, drilling machines, and saws to work on various materials. It’s best suited for small-batch and simple part production.

CNC processing means all manufacturer processes use computer-controlled machining, It is more efficient and accurate, mainly used for bulk production.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Wellste provides Low MOQ for Machined Heatsink. 1pc sample is free for you to check our quality.

Yes, Wellste is pleased to provide Machined Heatsink for you check the quality.

We are a manufacturer with OEM/ODM service.

Copper Passivation/Aluminum Anodized

It is only taking 7-10 days to complete your sample if the sample size is in stock.

For custom Machined Heatsink, It takes a little bit long time to make extrusion tooling, commonly it requires 30-35 days finish.

Products You May Looking for

Wellste: Your Professional Machined Heatsink Manufacturer and Supplier

Wellste machined processing has two types: manual processing and CNC processing.

Manual processing involves workers using machinery like milling machines, lathes, drilling machines, and saws to work on various materials. It’s best suited for Mass production but simple part production.

CNC processing means workers use computer-controlled equipment for machining, it is use for small prototype and bulk production.

Wellste will choose the best way to produce your heatsinks according to your project situation.

In addition to the machined heatsinks, Wellste is also proficient in producing other CNC machined aluminum parts. Such as aluminum CNC milling parts, CNC drilling parts, aluminum CNC turning parts, aluminum prototype machining, and so on.

Wellste machined heatsink is famous for its high precision, quality, and free design services. We fully understand customers’ strict requirements. To ensure exceptional accuracy and precision, we employ cutting-edge machining equipment and technology.

Wellste CNC machines are high-performance, they have precision down to the micrometer level. These machines cut and shape machined heatsinks, ensuring that the dimensions and forms meet design requirements.

Wellste places significant emphasis on product quality inspection. We possess advanced testing equipment to ensure that each heatsink meets the highest accuracy standards.

As a one-stop production manufacturer, we cover every step from material selection to transportation, providing customers with reassurance and satisfaction.

Wellste machined heatsinks have gained popularity worldwide. Our customers include the United States, the United Kingdom, Germany, Australia, and the United Arab Emirates.

Are you looking for a way to improve machined heatsink efficiency? Whether it’s electronics, aerospace, or medical equipment, Wellste machined heatsink is perfect for all commercial and industrial applications!

Click here to find out more about our machined heat sink now!