- Improve your brand image

- Support to any shape or size

- Various finishes for you to choose

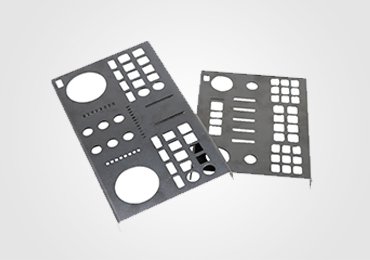

- High precision cutting and smooth edge

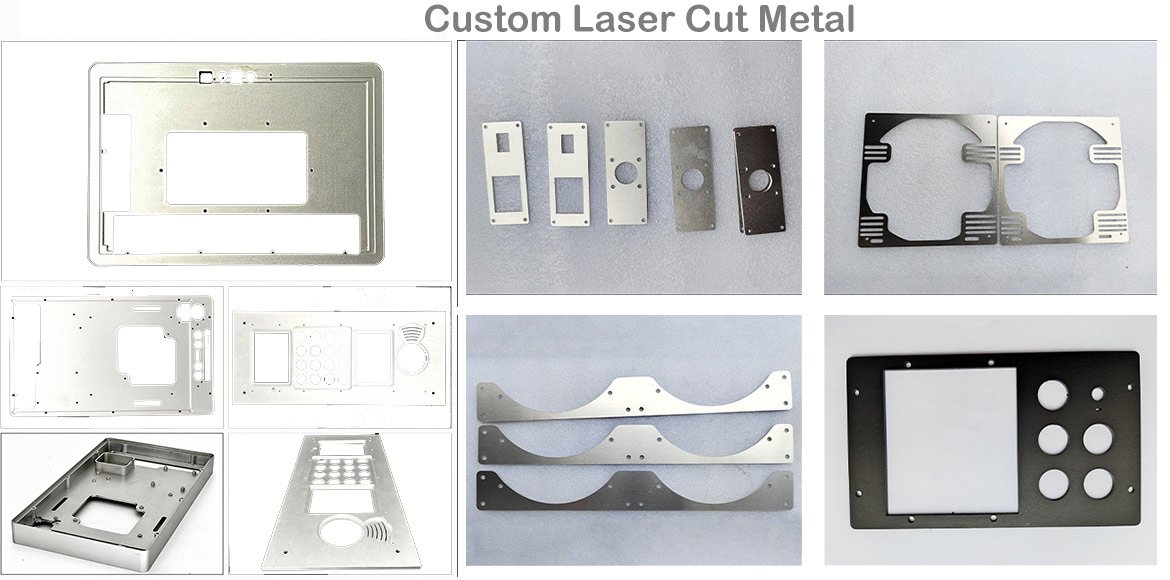

Custom Laser Cut Metal

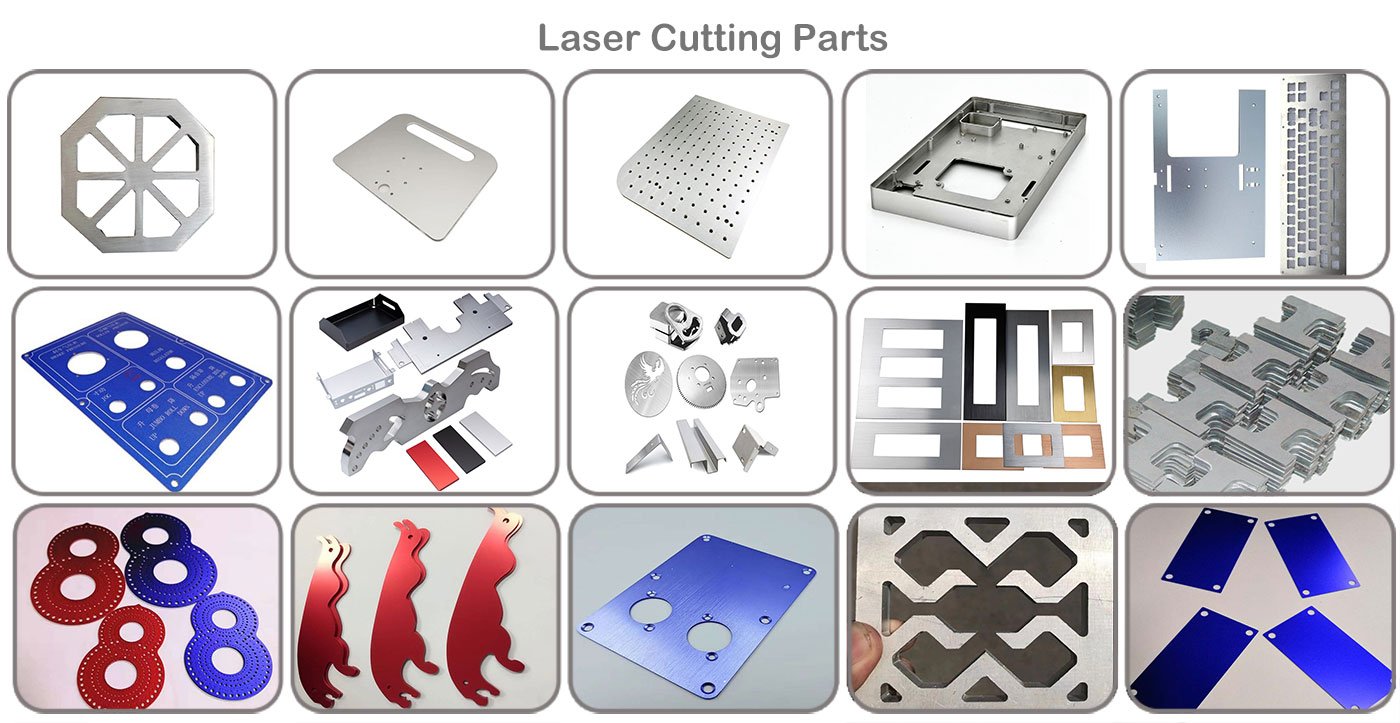

Laser cutting uses a very high precise laser beam to cut materials. This convenient process types has many applications, especially in metal parts industries and manufacturing.

It can cuts various materials, such as metals, plastics, wood, or other materials. Laser cutting focusing a high-energy laser beam onto a very small point. it can generating a sufficiently high energy density to melt, vaporize, or remove the material near that point.

Your Premier Custom Laser Cut Metal Supplier

Through controlling the laser beam position and intensity, it can create the desired cutting shape on the material.

Different materials has different laser cutting types, such as melting cutting, oxidation cutting, gasification cutting, and conduction cutting.

Melting Cutting: In laser melting cutting, the laser beam melts material, and gas blows away molten material, creating a cutting seam.

Oxidation Cutting: Oxidation cutting uses oxygen as an auxiliary gas, by chemical reaction to release lots of heat. It is suitable for materials like carbon steel.

Gasification Cutting: It uses a density laser beam to transfer energy into heat, and then raise the material to its evaporation point. This cutting type well for various materials, including carbon, certain plastics, and wood.

Conduction Cutting: To handle easy heat damage materials, it uses rapid rates to achieve controlled fractures. The thermal makes mechanical deformation and forms gaps. It is applicable to ceramics.

Compared with other cutting processes, there are many advantages of laser cutting.

Wellste laser cutting machines precision is very high. We strictly control the laser cutting accuracy, generally within 0.1 mm, and the dimensional accuracy of the cut parts can reach ±0.05m. It can meet most industrial production requirements.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Wellste: Your Professional Custom Laser Cut Metal Manufacturer and Supplier

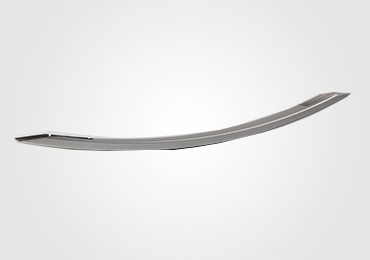

A great advantage of laser cutting is that the machine does not touch the metal surface, preventing the metal from being scratched by the machine.

Wellste laser cutting process is fast and efficient, and the cut surface is very smooth. In addition, it can also make various shapes, such as some simple patterns, lines, angles and holes.

Laser cutting does not limit the cutting materials. Not only metal, but plastics, wood, paper, etc. can also be cut by laser. Moreover, cnc laser cutting machine do not require frequent tool replacement, saving time and costs.

Many materials are suitable for laser cutting, such as carbon steel sheets, alloy steel sheets, and aluminum alloys sheets.

Aluminum alloys sheets has good thermal conductivity and cutting performance. Laser cutting works well with various aluminum alloys.

Aluminum laser cutting belong to melting cutting, with auxiliary gas blowing away the melted material to achieve a better cutting surface quality. aluminum laser cutting parts usages are very wide in daily life.

Laser cutting good in cutting carbon steel, it can cuts well on various carbon steel plate.

Various types of stainless steel, such as 304 stainless steel and 316 stainless steel, also can using laser cutting.

Most alloy steels can use laser technology effectively, And the cutting surface is smooth and flat.

Other metals like copper, brass, titanium, titanium alloys, and nickel alloys also can cut using laser cutting.

Generally, laser cutting thickness depending on different machines and laser energy levels. The laser cutting metal thickness range between very thin to relatively thick.

Those are kinds of metal materials laser cutting thickness range:

Usually, laser cut stainless steel thickness ranging is 0.5-25mm.

Due to aluminum has high thermal conductivity, the laser cutting thicknesses ranging is little wide, typically ranging from 0.5-30mm.

It should be noted that factors such as different laser cutting machines, power and settings will affect cutting capabilities.

Based on high or low power, Laser cutting machines has difference types. They are Low power laser cutting machines, medium power laser cutting machines, and high power laser cutting machines.

Low power laser cutting machines power below 1000W, it is use for thin materials. The maximum cutting thickness is about 4mm, and the laser cutting speed is fast, generally around 30m/min.

Medium power laser cutting machines power is 1000W-20000W. It is suitable for medium thick materials. The maximum cutting thickness is about 16mm, and the laser cutting speed is moderate, generally around 10m/min.

High-power laser cutting machines power is more than 20,000W and is suitable for thicker metal materials. The maximum cutting thickness is about 30mm, and the laser cutting speed is slow, generally around 5m/min.

Wellste offers 3 types of laser cutters with different power options to meet various cut thickness requirements for your products.

Wellste offers custom laser cutting services. We have advanced laser cutting equipment and technology, ensuring your products get high precision cutting.

Wellste laser cutting service has various shapes and sizes of metal materials to meet your requirements, ensuring clear and accurate cutting flat.

Furthermore, Wellste custom laser cut metal provides a wide range of metal options, including aluminum, steel, stainless steel, and more. Whether it’s flat materials or pipes, we all can cut smoothly.

Wellste custom laser cutting services strictly controls product quality, every piece of cut metal meets national standards. high-quality materials and conduct strict quality checks to ensure product durability and reliability.

Wellste is always customer-oriented, providing 24×7 Customer service. Our team maintains close communication with customers, understanding and meeting their needs, ensuring the best solution for their projects.

Get an inquiry now and start your project today!