Wellste thin wall aluminum extrusions are available in a variety of shapes and sizes, suitable for a wide range of applications. They can be customized with additional features such as surface finishes, drilling, and cutting, to meet the specific needs of your project.

Design phase communication

In February 2022, we received a custom aluminum extrusions inquiry from a customer.

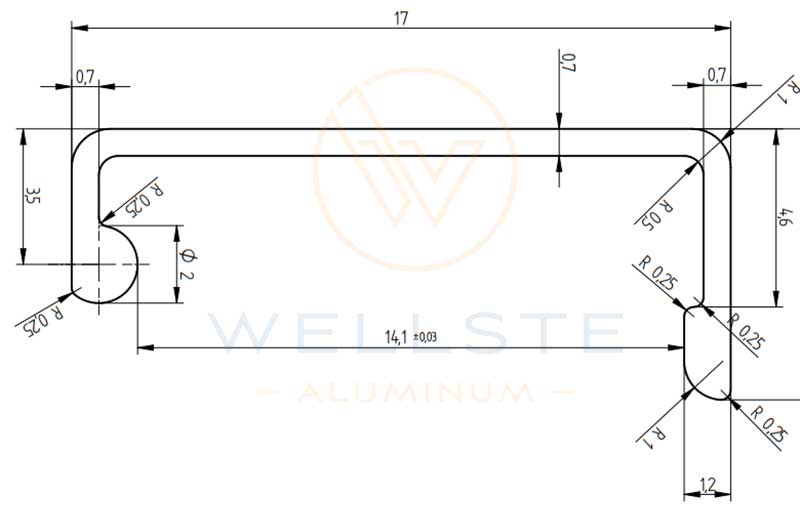

The customer is an LED lighting manufacturer looking for thin wall aluminum extrusion with a wall thickness of 0.7mm and precise tolerances.

Customer comes from German so that places high importance on aluminum extrusion profiles quality and tolerance.

Technical negotiations

After our technical evaluate, we can achieve a wall thickness of 0.7+/- 0.1mm, but no thinner.

The customer needs to assemble this LED aluminum extrusion with another part, so the important dimensions of 14.1mm and 14.5mm are also critical.

The customer’s drawing marks a tolerance of ±0.03mm.

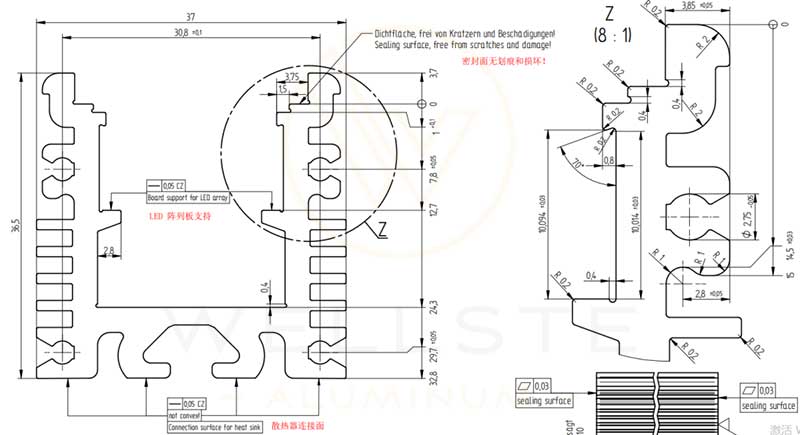

The customer requires these two parts to be assembled and disassembled multiple times with uniform force.

The thinner the cross-section LED corner profile (0.7mm; 0.6mm; 0.5mm), the greater its flexibility, and larger tolerance of the opening width accordingly.

The customer needs to install and remove the clamp multiple times to replace different optical devices and diffusers in the light.

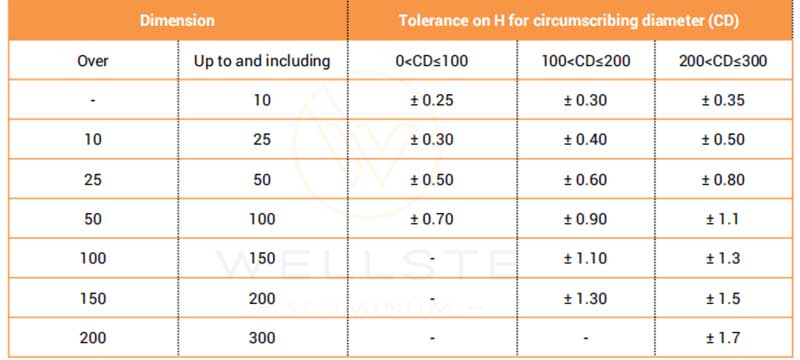

We checked the European aluminum profile extrusion standard tolerances, and according to the European standard EN-755-9 tolerance, the standard tolerance range is as follow:

After our technical evaluation, we can only achieve ±0.3mm.

The customer is still in the design phase and does not accept the standard tolerances we proposed.

The customer asked: If the opening width of the led extrusion profile after extrusion deviates too much, can it reach the size through further processes? Cold forming, such as rolling or bending?

These processes could reduce the tolerance range, but considering the customer’s annual demand of 200 meters, an additional processing step after extrusion would be costly and not economically viable.

Typically, for customers with assembly requirements, we ensure successful assembly based on standard tolerances.

If the accessories are not produced by us, the customer can send us a sample, and we will ensure during aluminum extrusions production and quality inspection that there are no assembly issues.

If you’re interested in learning more about Wellste thin wall aluminum extrusions, visit our website at https://www.wellste.com/thin-wall-aluminum-tubing/ for more information.