Aluminum is widely used in applications from electronics like Macbook and smartphone chassis to door handles and metal railings. If you’ve ever handled these objects you’ll notice a different feel, texture, and weight.

Aluminum attracts many purposes because of its light weight. It has an optimum strength-to-weight ration and a low melting point that can easily alloy it with other metals.

As an experienced engineer at Wellste with years of aluminum manufacturing experience, I can confidently say it’s extremely rare that anyone designs something with pure aluminum.

Often, pure aluminum lacks the ideal qualities like toughness and machinability.

This is why there are standardized aluminum alloys or aluminum grades that have superior characteristics.

In this article, I will explain what aluminum grades are. How can you differentiate between them? And which aluminum grade can suit your project with examples.

Aluminum as a Metal

Before we delve into aluminum grades, you need to understand aluminum metal and why there is a need to alloy aluminum with other metals.

Aluminum is a non-ferrous metal found everywhere. Aluminum looks similar to stainless steel, a silvery metal but is nothing like it. It is lightweight, has good electrical conductivity, and takes advantage of corrosion resistance.

Aluminum can be easily alloyed with many metals because it has a relatively low melting point. It can easily bind with clays and composites, which is why most aluminum comes from a mineral containing ore called bauxite.

Aluminum is one of the few metals that can be recycled with minimal losses. Most aluminum products are made from recycled aluminum because the recycling process costs a fraction of the ore refining process.

Characteristics of Aluminum

All aluminum grades are bound to have some characteristics of aluminum, such as mechanical properties.

Aluminum is a lightweight metal. It has a density of 2,710, Kg/m3 almost three times less than that of Iron. Steel and iron have much higher tensile strength; however, when considering the strength-to-weight ratio, aluminum is far superior to steel alloy.

Aluminum is conductive. You can learn more about the electrical conductivity of aluminum from our guide.

It can grow an oxide layer which can prevent it from rusting. It is one of the most abundant metal around the world because of its recyclability and corrosion resistance. It is also highly ductile.

What is Aluminum Alloy?

It is a mixture of aluminum and another metal or non-metal. Pure aluminum has inferior properties to its alloys, with the exception of electrical conductivity.

There are hundreds of aluminum alloys, and new alloys are constantly made, which requires a governing body to categorize and officiate such alloys.

The Aluminum Association is in charge of overseeing the trade and fabrication of aluminum. They have the authority to name and categorize different grades of aluminum.

There are different alloying elements used to produce different grades of aluminum and different manufacturing processes used to make aluminum alloys.

Grades of aluminum, like the 6000 series and 7000 series, are sub-categories of types of aluminum alloys. Wrought aluminum alloys and Cast aluminum alloys are the major classification among aluminum grades.

Both have slightly different properties because of how they are produced.

Wrought Aluminum Alloy

Wrought aluminum alloys are crafted using an extrusion process. Aluminum is heated below its melting point and free-forged under heavy loads or extruded from dies to make wrought aluminum. Such mechanical loads and stresses result in a change of shape, size, or structure.

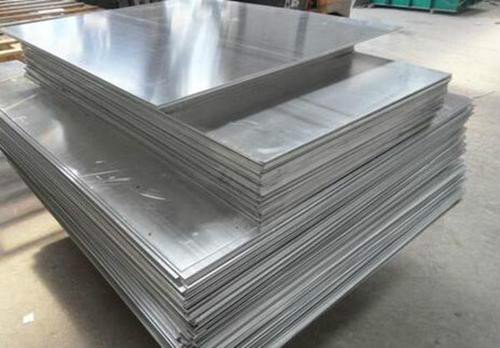

The process starts with smelting aluminum and coalescing it from its source. Here molten alloys are added to the aluminum, and the mixture is cast into aluminum plates or billets.

The aluminum plate or billet is heated to a high temperature below its melting point and mechanically rolled, extruded, or worked through dies to produce wrought aluminum alloys.

The different composition of alloying elements in wrought alloys gives different series or grades of aluminum.

Wrought aluminum alloys have the following properties

- Better strength

- Better ductility

- Smoother surface

- Anisotropic properties

- Consistent grains in structure

- Higher fatigue resistance (applications involving repeated loading)

Cast Aluminum Alloy

More often, you’ll find complex products made of cast aluminum alloys. Cast aluminum alloys are made from a similar smelting and coalescing process with the addition of alloying elements poured into molds.

The cast alloy cools in the die or sand mold and takes the shape of the mold.

Casting aluminum alloys is a more straightforward, more cost-effective process that produces complex shapes at the cost of a few desirable properties.

Cast alloys have

- Lower strength

- Susceptible to defects

- Suitable for complex shapes and quick designing

- Uniform properties

- Isotropic properties

Nomenclature of Different Aluminum Grades

If you’ve come across aluminum products you’ll find their names in digits. For example, AA6061. There are three main aluminum designation systems. The most popular is the Aluminum Association designation which follows a four-digit numbering.

For cast alloys the first digit identifies the primary alloying element, and the last digit after the decimal point tells if there’s any modification.

For wrought alloys, the first digit identifies the primary alloying element, and the last three digits separate it from other alloys in this group. There’s no decimal, but it can have extra letters or digits to convey more information.

For example, AA 6063-T5, where 6 indicates magnesium and silicon, 0 indicates unmodified alloy, and 63 differentiates it from other alloys in the group. The T-5 tells us it has undergone a quenching heat treatment process.

Aluminum Grades: What are the Types of Aluminum, and How are They Classified?

Aluminum grade is another name for aluminum alloy. With the basics like aluminum naming, and wrought alloys vs cast alloys out of the way, we can now delve deeper into types of aluminum grades and their classification.

First, an aluminum grade can be easily identified by its four-digit name. If this name has a decimal in the 3rd and 4th digit (6xx.x), it is a cast alloy; if it doesn’t have a decimal point (6xxx), it is a wrought alloy.

Wrought Alloys

Wrought alloys are a class of aluminum alloys that are mechanically worked through and have their AA designations beginning with 1xxx series and go up to 8xxx series. The word wrought itself means deformation while still solid.

Here’s a summary of the types of aluminum grades

| Series | Alloying Elements

(Major Elements Bolded) |

Tensile Strength (MPa) | Properties | Major Applications |

| 1000 (Natural impurities) | Silicon (0.07 – 0.25);

Fe (0.07 – 0.40); Cu (0.003 – 0.05); Mn (0.01 – 0.05); Mg (0.01 – 0.05); Cr ( extremely small to none); Zn (0.015 – 0.05) |

100 – 180 | Corrosion resistance

Good thermal conductivity |

Heat Exchangers and Conductors |

| 2000 | Silicon (0.20 – 1.3);

Fe (0.07 – 1.4); Cu (1.8 – 6.8); Mn (0.1 – 0.50); Mg (0.05 – 1.8); Cr ( 0.10 ); Zn (0.10 – 0.5) |

100 – 140 | Increased strength

Increased toughness Decreased corrosion resistance |

Aerospace and defense parts |

| 3000 | Silicon (0.20 – 1.1);

Fe (0.40-6.8); Cu (0.05 – 2.2); Mn (0.02 – 1.8); Cr ( extremely small ~ 0.02); Zn (0.05 – 1.8) |

110 – 210 | Ductile and Formable

Increased corrosion resistance |

Heat Exchanger |

| 4000 | Silicon (0.20 – 21.5);

Fe (0.40-6.8); Cu (0.05 – 5.4); Mn (0.02 – 1.0); Cr ( extremely small ~ 0.02); Zn (0.05 – 1.8) |

Increased strength weldability | Welding wire | |

| 5000 | Silicon (0.08 – 0.4);

Fe (0.10 – 0.7); Cu (0.05 – 0.35); Mn (0.10 – 1.2); Mg (1.1 – 5.2); Cr ( 0.05 – 0.35); Zn (0.15 – 0.8) |

160 – 420 | Increased strength and resists corrosion | Marine applications |

| 6000 | Silicon (0.20 – 1.8);

Fe (0.15 – 1.7); Cu (0.15 – 1.0); Mn (0.10 – 0.5); Cr ( 0.05 – 0.40); Zn (0.05 – 0.25) |

100 – 260 | Weldable alloy

Great strength |

Architecture and construction |

| 7000 | Silicon (0.10 – 0.5);

Fe (0.12 – 14); Cu (0.10 – 2.5); Mn (0.05 – 0.8); Cr ( 0.04 ~ 0.35); Zn (3.8 – 8.2) |

150 – 305 | High strength alloy | Aerospace and defense parts |

| 8000 | Silicon (0.20 – 1.1);

Fe (0.40-6.8); Cu (0.05 – 2.2); Mn (0.02 – 1.0); Cr ( extremely small ~ 0.02); Zn (0.05 – 1.8) |

Special properties |

You can view the complete detailed list with chemical composition limits by the Aluminum Association here.

Aluminum Grade Series 1XXX

The 1000 series aluminum grade is divided into two groups. The first starts from 1050 and goes to 1098 grade. This is pure aluminum in its unalloyed form and comes under AA natural limits.

These wrought aluminum grades have some ranges of impurities like silicon and iron that are usually below 1%. Typical aluminum purity ranges from 99.5% to 99.9%. The percentage of these impurities and alloys divide the 1000 series aluminum in its grades.

Typical examples: 1050, 1070, and 1080A

The second group of 1000 series aluminum is alloyed aluminum.. This group starts from 1100 grade to 1199. It has a high purity percentage of aluminum but finds AA designations.

Typical examples: 1100, 1200, 1345

1000 series aluminum grades are non-heat treatable aluminum alloys. They have good corrosion resistance and are great conductors. Because they are mostly pure aluminum, they are ductile and extremely machinable.

They are non-heat treatable aluminum alloys because they lack any significant alloying elements that can contribute to strengthening during phase formation. Heat treatment also doesn’t work because it tends to soften at high temperatures.

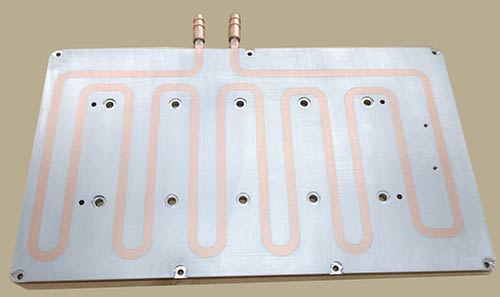

1000 series aluminum alloys have good thermal conductivity and have applications in heat exchangers.

Aluminum Grade Series 2XXX

Aluminum series 2XXX has copper as the major alloying element. It has traces of other metals and silicon, including Magnesium, Manganese, Chromium, etc in small quantities.

2000 series wrought alloy has excellent machining capabilities due to copper addition and it also has high to moderate strength.

These high-strength aluminum alloys can be heat treated for further strengthening but lack corrosion resistance because of copper oxidation.

The poor rust resistance means often 2000 series aluminum has to be anodized or coated for outdoor applications.

Typical examples: 2014, 2024

Aluminum Grade Series 3XXX

Manganese serves as the primary alloying element in this aluminum alloy, and certain grades within this alloy may additionally incorporate copper as a major alloying component

Aluminum-manganese alloys are non-heat-treatable aluminum alloys mainly because manganese lacks precipitation or phase hardening due to heat.

3000 series aluminum has excellent corrosion resistance, and machinability, and can be formed into various shapes easily. These alloys have good weldability and can be used for structures.

Typical examples: 3003, 3105

The 3000 series aluminum finds frequent use in the construction and development sectors.

Aluminum Grade Series 4XXX

4000 series aluminum has multiple main alloying elements. The highest by composition is usually silicon but it also contains copper and magnesium among other elements.

4000 series aluminum has comparatively moderate strength and a lower melting point.

This aluminum alloy has significant fluidity and weldability that often employs this grade in welding applications. The moderate strength means the welds don’t crack.

Typical examples: 4043

Aluminum Grade Series 5XXX

5000 series aluminum alloy is aluminum-magnesium alloy. Magnesium is the main alloying element and they have good corrosion resistance.

5000 series aluminum alloys can be strain-hardened for increased yield strength but this also decreases their ductility.

They are primarily used in marine applications including hulls and railings on boats because of their exceptional corrosion resistance.

One important thing worth understanding is despite being heat-treatable wrought alloys, they are not suitable for applications with high temperatures.

These grades of aluminum are primarily used in projects where corrosion resistance is a concern. Applications in aerospace, marine, or seawater.

Typical examples: 5052, 5083

Aluminum Grade Series 6XXX

6000 series aluminum is a widely used aluminum grade. It is found in many structural components like bike frames, electronics, and buildings.

Silicon and magnesium are its main alloying elements, and their typical ranges do not exceed 2%. Exceptional strength can be attained in these alloys through the application of heat treatment.

They have multiple tempers or heat treatment processes. Many 6000-series aluminum alloys have T4 or T6 in their name. This is also called its temper.

The T4 tempered aluminum alloy is a solution heat treated for alloying elements to become part of the aluminum matrix.

T6 is another heat treatment process to increase the strength of aluminum, where aluminum alloy after solution heat treatment is kept at a lower temperature for precipitation hardening.

The magnesium and silicon contribute significantly during the heat treatment. Magnesium contributes to precipitation formation with aluminum during T6 heat treatment and the silicon forms Mg2Si which results in increased strength.

6000 series aluminum is versatile and displays great formability characteristics, corrosion resistance, and weldability.

Typical examples: 6063, 6061, 6067 T5

Aluminum Grade Series 7XXX

These highest-strength aluminum alloys’ main alloying elements include zinc and, in a few cases iron.

They are heat-treatable aluminium alloys and display exceptional strength because of solid solution strengthening. They follow a similar heat treatment and temper process as the 6000 series but the precipitates forming are MgZn2 which contributes to much higher strength.

The precipitation anomalies act as barriers to flowing dislocations and prevent cracks and voids from forming at a microscopic level.

7000 series aluminum grades can be compared to steel for their strength and weigh much less than steel.

They have great fatigue resistance, which means they can be used in applications involving repeated loadings. Their only downside is low corrosion resistance.

7000 series is used in armor plating, military, aerospace, and sporting industries.

Typical examples: 7075

Aluminum Grade Series 8XXX

8000 series aluminum is a unique, newly developed series of aluminum grades. Lithium is the main alloying element in 8000 series aluminum.

Lithium is considerably less dense than aluminum and forms fine precipitates with aluminum’s lattice resulting in strengths up to 500 MPa.

Lithium also gives 8000 series aluminum impressive elongation properties. These alloys can be bent, stamped, and undergo extrusion processes.

They have good corrosion resistance and weatherproofing. They are non-toxic and often used to package perfumes.

Typical examples: 8011, 8021, 8090

Cast Alloys

Cast alloys are aluminum alloys that follow the International Alloy Designation System and have a dot or decimal point in the alloy name. For example, A380.0

Cast alloys, as the name suggests, are a product of the casting process. Pure aluminum is melted and mixed with other metals to form the alloys, and the mixture is poured into dies to get a specific shape or into billet castings to produce ingots.

The classification of cast alloys follows a structure similar to that of wrought alloys, with the initial digit indicating the primary metal constituent. In cast alloys, the first digit is excluded from being 6.

Cast aluminum series have relative freedom with their limits because most cast alloys are post-processed into something different.

This table summarizes their alloying limits.

| Series | Alloying Limits (Approximate) |

| 1XX.X | Aluminum (99%) |

| 2XX.X | Copper 4.5% |

| 3XX.X | Silicon (up to 17%), Copper and Magnesium |

| 4XX.X | Silicon (up to 12%) |

| 5XX.X | Magnesium (4.5 – 10%) |

| 7XX.X | Zinc (6.5%) |

| 8XX.X | Tin |

Series 1XX.X

1XX.X series aluminum cast alloys have more than 99% aluminum purity. They have all the properties expected from pure aluminum like corrosion resistance, thermal conductivity and weldability. 1xx.x are non-heat treatable aluminum alloys.

Series 2XX.X

Aluminum alloys in the 2XX.X series feature copper as their primary alloying element, enhancing machinability while rendering them more susceptible to corrosion. These are high-strength alloys but lack ductility due to a grain size difference in the alloy.

Series 2xx.x is a heat-treatable alloy, but it is prone to a phenomenon called hot cracking. This is when a temperature gradient in the grains of the alloy causes cracking.

Series 3XX.X

3XX.X series have high percentage of silicon, along with copper or magnesium as its alloying element. They are also heat-treatable aluminium alloys with high strength, crack resistant, and excellent machinability.

Series 4XX.X

Aluminum alloys in the 4XX.X series consist solely of silicon as an additional constituent.. These silicon alloys are high in strength, have excellent corrosion resistance, and great weldability.

Series 5XX.X

Aluminum alloys in the 5XX.X series are characterized by having magnesium as their primary alloying element.

They resist corrosion and are non-heat treatable alloys. Their strength is less than 2XX.X alloys but have great machinability and fluidity that is useful for casting.

Series 7XX.X

Series 7xx.x are zinc alloys. These alloys have good fatigue resistance and are often used in structures that require lightweight and are often regarded as high-strength alloys. Various heat treatment processes can strengthen series 7XX.X.

Series 8XX.X

This is a relatively new addition to AA’s alloy classification. These alloys use tin as their main alloying element and are non-heat treatable. They have special applications and are purposefully built.

Applications Of Aluminum Grades With Examples

Aluminum is a widely used metal. Different grades suit different purposes. This section will help you understand the general applications of aluminum grades.

Wrought Aluminum Series

1000 Series

1000 series aluminum is commercially pure aluminum. It is mostly used in heat exchangers for its good thermal conductivity, conductive materials, and reflectors.

2000 Series

These aluminum grades have copper, which gives them excellent machinability. They display great strength at high temperatures and are specially used in the aerospace industry.

3000 Series

These aluminum grades are used for cooking utensils because of their corrosion resistance and conductivity. They are also used for other food packaging and soda cans like 3004.

4000 Series

4000 series has excellent weldability and is often used as electrodes.

5000 Series

This series has applications in the sheet metal industry. Grades like 5052 have wide final applications as sheet metal like fuselage.

6000 Series

Also known as architectural aluminum. It is one of the strongest alloys available and is used as a structural metal.

6061 is a heat-treatable alloy that is used in aerospace and automobile components. They are also used to manufacture extrusions and dies.

7000 Series

7000 series grades can bear great amounts of stress. If you plan to use something that requires excellent strength this is an option.

8000 Series

This special alloy is reserved for many user-friendly uses like perfume packaging, food-grade foils, etc.

8011 is an example of the 8000 series.

Cast Aluminum Series

Cast aluminum series is not widely used as the final grade and often undergoes many processes.

2xx.x Series

These alloys are directly cast to make some tough components in the automobile and aircraft industry. Pistons, cylinder heads, and other general-purpose castings.

3xx.x Series

3xx.x has improved corrosion resistance over the previous grade, and for this reason, it is used for casting products for the marine industry like the 357.

4xx.x Series

These are silicon alloys with good wear resistance. Mostly used in pump housings and high-stress applications.

5xx.x Series

This series has improved pressure-retaining capability. 514 grade is used for making parts in automotive and aircraft production.

7xx.x Series

This grade is used in laptop components, ports, electronic housings, etc.

8xx.x Series

8xx.x series are good castable heat-resistant alloys. 850 is used for engine bearings and industrial uses requiring high-temperature applications.

Factors to Consider When Choosing an Aluminum Grade

Identifying the right aluminum alloy is crucial to match the specific requirements of your project.

So many aluminum grades exist because of the possible uses of aluminum, its properties, and its weight. There’s a large possibility one of the aluminum alloys matches your purpose.

Before going into aluminum alloys, it is important to understand the design parameters of your part. How much load it can support? Does it require paint? the type of surface finish you’re looking for, etc.

Here’s the best feasibility analysis for selecting aluminum grades for your project.

Machinability

Sometimes, you’re restricted by machining capability and tool strength. If you’re designing something for precision and lower tooling costs, you can choose free machining alloys

Weldability

Casting metals into a desired shape is feasible for small designs. For most applications, aluminum has to be joined using welds. For this reason, it is important to consider the weldability of the alloy as a factor.

Corrosive Properties

Aluminum is naturally corrosion-resistant. However, some grades have better corrosion resistance than others. If your final application of aluminum is in a moist environment grades like 5052

Strength

One reason so many aluminum grades are produced is because of the variation in tensile strength. As a designer or producer, you must know the required strength of aluminum’s application.

You can get into a quick discussion about suitable materials and aluminum products using this link.

Conductivity

If you’re looking for a cheaper alternative to copper with high conductivity. New alloys like AA8079 offer the best conductivity but conventional alloys like 1050A are still heavily used.

Heat Treatability

Heat-treating aluminum is important for weak alloys. Increasing their strength can lead to newer applications of the same alloy. Not all aluminum grades can be heat-treated to improve strength. A great heat-treatable alloy is Aluminum 2024.

Get The Right Aluminum Grade Through Wellste

Finding the right grade for your application can take a whole lot of research and technical expertise. You can always research your project’s application or leave it to our highly technical engineering team.

You can easily reach our team using this link.