- In-house testing before shipment

- One-stop custom Aluminium Solutions

- Offer design to final usage extensive solution

- Custom aluminium motor body to your specifications

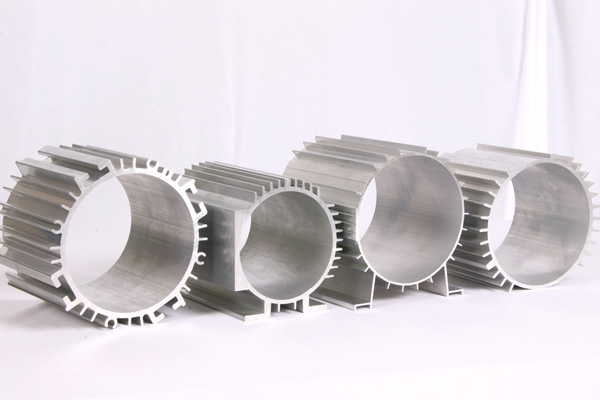

Aluminium Motor Body

Wellste aluminium motor body is also named as aluminium motor enclosure. This is a special kind of aluminium shell with extrusion forming, useful to place measuring tools and other uses. Its general use is to secure all internal motor parts.

Wellste: The Top Aluminium Motor Body Manufacturer

Why Wellste Aluminium motor body? Development and research prove that aluminium motor body is a good replacement to aluminium casting shell. Because it easily resolves the problems of sand holes, porosity, and any other defects.

Wellste has advanced precision processing equipment that enhances the competence of the deep aluminium motor body fabrications. It runs very quietly and smoothly, producing a satisfying quality of aluminium motor body.

Our version of aluminium motor body brings countless advantages to your applications, whether business or personal applications. In heat dissipation, our aluminium motor body is superior compared to other materials.

It has high solubility that used to keep its temperature within an exact range. Regarding such features, the Wellste aluminium motor body received high praise in both local and domestic markets.

| Item Name | Aluminium Motor Body |

| Material | Aluminium Alloy 6000 series, 5000 series, 7000 series, Other special inquired |

| Temper | T4 T5 T6 |

| Quality Standard | GB/T 5237-2008,GB/T 6892-2015 |

| Length | 3-6 Meter, or as your inquire |

| Surface Finish | Mill Finish, Natural Anodized, Hard Anodized |

| Open Mould | 10-15 days |

| Production Time | 20-25 days |

| Payment | T/T, L/C, etc |

| MOQ | 500KG each one |

| Deep process | Magnetic processing, micro-machining, precision machinery, insulation treatment, winding manufacturing, fine chemical industry |

| Standard Packaging | PE shrink film, Non-woven Fabric, Craft paper, Carton, Or customized packing |

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Yes, Wellste is pleased to provide Aluminium Motor Body for you to check the quality, Normally sample is for free for saving cost, But it will require tooling costs if custom size.

Wellste always supply pre-production Aluminium Motor Body sample before mass production, and we always have a final Inspection before shipment;

We are a manufacturer with OEM/ODM service.

Wellste can do Mill Finish, Natural Anodized, Hard Anodized, powder coating, and PVDF for your Aluminum Motor Body.

Wellste provides Low MOQ for Aluminium Motor Body. 1pc sample is free for you to check our quality.

It only takes 5-7 days to complete your order if the Aluminium Motor Body size is in stock. For custom Aluminium Motor Body, It takes a little bit long time to make extrusion tooling, commonly it totally requires 25-30 days to finish production.

Related Products

Wellste: Your Professional Aluminium Motor Body Supplier

Get a high-quality aluminium motor body only in Wellste. We have professional and well-experienced engineers, will help to fabricate aluminium motor body based on your specifications.

In Wellste, there are many fabrication processes of aluminium motor body including magnetic processing, micro-machining, precision machinery, insulation treatment, winding manufacturing, fine chemical industry, and other technologies.

To really ensure the quality of each aluminium motor body, these processes must be done. Precision testing tools are needed for that application as well. Wellste welcomes both new and old clients to negotiate business.

Robustly constructed, Wellste aluminium motor body is broadly used in hydraulic applications and household appliances. This is also mostly used in the industrial sectors. However, this product is lightweight, made from 6063 aluminium alloy material.

Wellste, as one of the leading manufacturer in China, supplies thousands of aluminium motor body that is customizable according to your demands. It is coated and anodized to achieve consistent color and surface tissue. Versatile and functional perfect for various applications.

In Wellste, there are different units of aluminium motor body that featured modular layouts. Thousand of options are found at Wellste, all in good quality and conditions.

Wellste is a well-experienced ISO 9001:2008 certified manufacturer, producing a custom and standard aluminium motor body. We also have nearly 20 years of experience in the field of fabrication, continuously meeting each requirement of demanding clients.

We are a noteworthy supplier and manufacturer working in China. We engineered sturdy, highly efficient, corrosion-resistant, maintenance-free, and durable aluminium motor body. All interested buyers across the country are free to bulk orders with us.

Contact us now! Let Wellste help your own business grow!

Aluminum Motor Body: The Ultimate FAQ Guide

Wellste team will today answer all questions you have been asking about aluminum motor body.

From design, specification, surface finish to applications – you will find all information about aluminum motor body right here.

Let’s dive right in.

- What Is Aluminum Motor Body?

- Is There A Difference Between Aluminum Motor Body And Aluminum Motor Enclosure?

- Which Are The Common Types Of Aluminum Motor Body Described By NEMA Standards?

- Why Use Extruded Aluminum Motor Body Instead Of Die Cast Aluminum Motor Body?

- What Are The Advantages Of Aluminum Motor Body?

- Which Are The Key Aluminum Motor Body Accessories?

- What Are The Customizable Properties Of Aluminum Motor Body?

- What Are The Available Aluminum Motor Body Sizes?

- Which Is The Best Alloy For Making Aluminum Motor Body?

- What Are The Distinctive Features Of Water-Cooled Aluminum Motor Body?

- How Does Foot Type Aluminum Motor Body Compare To Flange Aluminum Motor Body?

- What Is The Recommended Tolerance For Die Casting Aluminum Motor Body?

- Can You Perform Surface Treatment For Aluminum Motor Body?

- What Are The Applications Of Aluminum Motor Body?

- Which Are The Types Of Motor You Can House In Aluminum Motor Body?

- Are Aluminum Motor Body Water And Corrosion Resistant?

- What Are The Advantages Of Aluminum Motor Body Over Cast Iron Motor Body?

- Do You Manufacture OEM Aluminum Motor Body?

- What Is The Preferred Temper For Extruded Aluminum Motor Body?

- How Much Does Aluminum Motor Body Cost?

- What Is Your Lead Time For Aluminum Motor Body Manufacturing?

What Is Aluminum Motor Body?

It is a special casing made from aluminum that covers the internal components of an electric motor.

These casing have extrusions as a special feature.

Aluminum motor body

The aluminum motor body comes with the following:

- Shell

- Panel

- Lining plate

- Support and other parts

Is There A Difference Between Aluminum Motor Body And Aluminum Motor Enclosure?

No, aluminum motor body and aluminum motor enclosure all refer to the same thing.

Which Are The Common Types Of Aluminum Motor Body Described By NEMA Standards?

The aluminum motor body will offer protection of the bearings, windings, and other mechanical components.

Besides, the protection is against chemicals, moisture, abrasion, and mechanical damage.

The NEMA standards ranging from MG1-1.25 to 1.27 highlight over 20 types of enclosures under the following groups:

- Open machines

- Machines with sealed or encapsulated windings

- Totally enclosed machines

Here is a list of the common types of the aluminum motor body as illustrated by NEMA standards:

Totally Enclosed Air Oven [TEAO]

This system is suitable for blower-duty motors and dust-tight fans.

Besides, the design is for shaft-mounted fans and belt-driven fans.

You must mount the motor of a totally enclosed air oven aluminum motor body within the airflow of fans.

Open Drip Proof [ODP]

This system will allow the circulation of air via the windings for cooling purposes.

Also, it will inhibit liquid drops from infiltrating the motor inside at an angle of 15 degrees from a vertical standpoint.

Besides, you will use an open drip proof aluminum motor body indoors, in a clean and dry location.

Explosion-proof Enclosures [EXPL]

This type of system has a totally enclosed unit.

For this reason, explosion-proof aluminum motor bodies can withstand the explosion of gases or vapor within the motor casing.

Therefore, explosion-proof enclosures will inhibit external ignition of the motors through flashing, sparks, or explosions.

Explosion-proof enclosures are suitable for use in hazardous scenarios.

For instance, it works well in an environment that has hazardous gases or dust.

Ensure the maximum operational motor temperature is below the ignition temperature of the gasses and vapors in the environment.

This will ensure that the explosion-proof enclosure for the aluminum motor body operates safely.

Also, the manufacture, testing, and design of explosion-proof motors are done following the requirements of the UL [Underwriters Laboratories].

Totally Enclosed Non-Ventilated [TENV]

This system will inhibit air within the unit and the environment from freely exchanging.

However, a totally enclosed non-ventilated aluminum motor body lacks cooling fans.

It, therefore, relies on convection for cooling to occur.

Besides, it lacks vent openings but is not airtight and the tight enclosure will inhibit the free exchange of air.

A totally enclosed non-ventilated aluminum motor body is suitable for scenarios containing dirt and is damp.

However, they are not suitable for extremely hazardous or moist areas.

Hazardous Location [HAZ]

The hazardous location aluminum motor body finds its classifications under the following requirements:

- Type of hazardous environment

- Traits of the material causing the hazard

- Possibility of exposure to the surrounding

- Maximum temperature level safe for the substance that creates the hazard

Besides, the National Electric Code [NFPA-70] defines the format that defines the information in:

- Classes

- Groups

- Divisions

- Temperature code structure

Here is a list of the hazardous location that the National Electric Code defines:

Class I

Group A of this class has acetylene

Group B contains hydrogen, butadiene, propylene oxide, ethylene oxide, and manufactured gases that have over 30ydrogen in volume.

Group C has the following:

- Diethyl ether

- Acetaldehyde

- Ethylene

- Cyclopropane.

Group D contains

- Acetone

- Styrene

- Toluene

- Propylene

- Acrylonitrile

- Ethylene

- Gasoline

- Dichloride

- Butane

- Methanol

- Xylene

- Ammonia

- Propane

- Isoprene

- Hexane

- Benzene

- Ethanol

- Methane (natural gas)

- Naphtha

- vinyl acetate

- Vinyl chloride

Class II

Group E in this class contains magnesium, aluminum, or other metallic dust similar in characteristics.

Group F has coal dust, carbon black, or coke.

Group G contains grain dust, flour, or starch.

Class III

In this class, you have ignitable fibers such as:

- Cotton

- Asrayon

- Excelsior

- Oakum

- Sisal

- Cocoa fiber

- Hemp

- Materials of similar characteristics

Totally Enclosed Fan Cooled [TEFC]

This type of system will prevent air within the aluminum motor body and the environment from freely exchanging.

Besides, a totally enclosed fan cooled aluminum motor body will not form an airtight frame.

There is a fan that attaches to the shaft of the system.

This fan will push air above the frame when it is operating hence, assist in the cooling process.

Also, there is a ribbed frame in a totally enclosed fan cooled aluminum motor body.

The ribbed frame will increase the surface area for cooling to occur.

A totally enclosed fan cooled aluminum motor body is the most versatile.

This system finds its application in pumps, compressors, directly connected devices, and industrial belt drives.

Totally Enclosed Washed Down [TEWD]

This system is sturdy as the design allows it to withstand the following elements:

- High-pressure wash-downs

- Highly humid locations

- Extremely wet environments

They are also available in the following enclosures:

- TEAO enclosures

- TEFC enclosures

- ENV enclosures

Totally enclosed washed-down systems are suitable for environments ridden with moisture or chemicals.

However, they are not suitable for use in hazardous environments.

Why Use Extruded Aluminum Motor Body Instead Of Die Cast Aluminum Motor Body?

Aluminum motor enclosure

Through new research and development, extruded aluminum motor body have replaced die cast aluminum motor body.

This is because extruded aluminum motor body solves issues relating to porosity, sand holes, and additional defects.

These issues are common in die cast aluminum motor body since they have a poor material density.

Also, extruded aluminum motor body solves issues about minimal corrosion resistance and surface roughness.

Both of these are common when using die cast aluminum motor body.

Precise modern processing devices such as CNC machines will enhance the efficiency of deep processing relating to the aluminum motor body.

Besides, it also solves problems with resistance to corrosion and surface roughness of electromechanical shells of the die cast aluminum alloys.

What Are The Advantages Of Aluminum Motor Body?

There are several benefits to using an aluminum motor body in your application.

Aluminum motor body are superior to other types of materials when it comes to dissipating heat.

The motor within the system will produce heat during its operations.

Besides, the aluminum motor body maintains the temperature in a specific range when the unit is operational for several hours.

Aluminum as a material contains high thermal solubility properties.

For this reason, manufacturers who make speed reducer motors will use aluminum shells.

Also, the aluminum motor body is lightweight than other materials due to the metallic characteristics of aluminum alloy.

This kind of trait makes it possible to use the aluminum motor body in a wide array of household appliances such as:

- Liquidizer machine

- Soybean milk machine

- Juicer machine, etc.

Also, aluminum alloy has suitable plasticity and especially aluminum alloy 6063 that has superior elasticity.

This makes it possible for manufacturers to make the aluminum motor body in a variety of shapes.

The flexibility will enrich the customers’ selection on the appearance of their aluminum motor body.

Besides, the aluminum motor body has a small density than the other commonly used metals such as copper or iron.

Also, the aluminum motor body produces no metal pollution or toxicity as the surface oxide is non-volatile.

Aluminum motor body as suitable thermal and electrical conductivity providing great performance in a short-distance transmission.

Besides, the aluminum motor body is chemically stable and is not magnetic meaning you can easily recycle the material.

Also, it has a small elasticity coefficient hence no risk of sparks during collision friction that enhances its performance.

Aluminum motor housing also emits minimal noise levels and is energy-efficient.

Which Are The Key Aluminum Motor Body Accessories?

The accessories you can use with aluminum motor body include the following:

- Brackets

- Lining plate

- Panels

- Support components

- Shells, etc.

What Are The Customizable Properties Of Aluminum Motor Body?

Custom aluminum motor casing

There is a wide variety of customizable properties you can find in the aluminum motor body.

Besides, you can customize the aluminum motor body according to your production needs.

Customization of the aluminum motor body can happen in the following areas:

- Surface treatment

- Diameter

- Size

- Length

What Are The Available Aluminum Motor Body Sizes?

The length of the aluminum motor body comes in lengths ranging from 3 m to 6 m, or as you would like to customize.

Which Is The Best Alloy For Making Aluminum Motor Body?

The best alloy you can use is 6063 aluminum alloy material since it is a very versatile and lightweight material.

Also, you can use aluminum alloy from the following series:

- Aluminum alloy 6000 series

- Aluminum alloy 5000 series

- Aluminum alloy 7000 series

What Are The Distinctive Features Of Water-Cooled Aluminum Motor Body?

The aluminum water-cooled motor body has extrusions and the circulation of cooling water happens within the inner shell lining.

This assists in dissipating heat that the motor generates during its operation.

Besides, this technique makes the heat dissipation not occur outside the system.

The water cycle in the water-cooled aluminum motor body replaces cooling fans.

How Does Foot Type Aluminum Motor Body Compare To Flange Aluminum Motor Body?

Here is how these two compare:

Flange Aluminum Motor Body

This system has sintered iron bush bearings that have lubrication throughout their entire lifespan.

The end shields can come either as:

- Pressed metal sheets with an integral or a separated flange

- Lightweight pressure aluminum

Flanged aluminum motor housing offers rigid and secure positioning.

Also, it allows the bearing to rotate within a clean surrounding.

Besides, you will bolt the flanged aluminum motor body to a foundation.

It also allows the external bearing ring to maintain its stationary position as the inner ring rotates.

Foot Type Aluminum Motor Body

For this system, you will mount the unit on a rigid foundation and they all have an integral feet construction.

This system has a robust structure, long service life, and reliable functionality.

What Is The Recommended Tolerance For Die Casting Aluminum Motor Body?

The recommended tolerance will vary from one die cast aluminum motor body to another.

Besides, the tolerance will range between 0.01 and 0.5

Can You Perform Surface Treatment For Aluminum Motor Body?

Surface treatment refers to the coating or the method of coating material.

There are a variety of surface treatments for aluminum motor body, each having its unique function and application.

The surface treatment will offer protection to the aluminum motor body.

Examples of surface treatments for an aluminum motor body include the following:

Aluminum motor body with different surface finish

Mill Finish

This type of surface treatment entails forming a texture on the aluminum motor body after exiting the rolling mill.

The texture is rough, lacking luster since there is no additional mechanical or chemical finish.

Anodizing

When anodizing an aluminum motor body, you will use an electrochemical process to form a layer of oxide on the surface.

The oxide film will therefore form a protective layer on the aluminum motor body.

Besides, anodizing needs you to apply no extra layer to the aluminum motor body.

The anodizing process will offer a protective layer that builds upon the existing aluminum material.

The oxide film will integrate fully into the aluminum due to strong molecular bonds.

Anodizing process protects the aluminum motor body and increases resistance to corrosion.

Also, the aluminum motor body will retain its appearance for a long time.

The hard and wear-resistant anodizing layer protects the underlying aluminum motor body thus enhancing its durability.

Besides, the layer of oxide will offer decorative properties as it allows the aluminum motor body to have several decorative colors.

It will retain the natural appearance of aluminum while making it acquire an attractive appearance.

During anodizing process, you can either use natural anodizing or hard anodizing.

Natural anodized surface treatment entails using an uncolored anodic film.

It is transparent and will show how the underlining aluminum motor body appears.

In a hard-anodized process, you will use a layer of oxides to harden the aluminum motor body.

This feature makes the aluminum motor body resistant to corrosion, hard, and durable.

Powder Coating

This coating will provide the aluminum motor body with a protective and decorative layer.

After several pre-treatments such as degreasing and rinsing, you will apply a powder coat through the electrostatic process.

Powder with a negative charge goes to the positively charged aluminum motor body.

The electrostatic process will form a temporary sticking effect of the coating.

Then, you will heat to cure the coating, and the coating will melt and flow hence forming a film of continuous liquid.

Besides, it is environmentally friendly since you do not use any solvents.

However, the final finish is a bit rough since the texture of granules is a bit visible.

Wet Paint

This process is useful when aesthetics is more important since it produces a smoother result.

Besides, you cannot powder coat to achieve certain decorative effects.

This process is simple since the dimension of the aluminum motor body is not an issue since you spray it in a spray booth.

Mechanical Finish

In this method, you will buff, polish, blast, sand, or grind the aluminum motor body.

The mechanical finish will enhance the surface quality of the aluminum motor body preparing it for more cosmetic finishes.

Pre-treatment

In this process, you will provide the surface treatment either through etching or cleaning with alkaline or acidic substances.

After cleaning, you will apply a pre-treatment coating that improves the paint or powder.

This effect will offer strong resistance against corrosion.

Bright Dipping

Here, you can bright dip the extrusion hence giving the aluminum motor body a specular or mirror-like finish.

Technicians will place the profile into a dipping solution such as a combination of nitric and hot phosphoric acid.

Besides, you can anodize the aluminum motor body after bright dipping to thicken the corrosion-resistant layer of oxide.

What Are The Applications Of Aluminum Motor Body?

An aluminum motor body finds its application in various fields such as:

- Household appliances

- Instruments

- Communication

- Smart cards

- Automation

- Electronics

- Sensors

- Precision machinery

- Industrial control

- Automobiles

Which Are The Types Of Motor You Can House In Aluminum Motor Body?

Some of the common electric motors you can use entail the following:

Aluminum motor body

AC Brushless Motors

These are among the most common motors in motion control.

AC brushless motors apply induction via rotating magnetic fields that the stator generates.

This will rotate the stator and the rotor synchronously.

Besides, AC brushless motors depend on permanent electromagnets to function.

DC Brushed Motors

In this motor, the placement of the stator affects the flow of current.

In some models, the placement of the brushes relative to the segments of the rotor bar is important.

Communicators are vital in DC brushed motor designs.

DC Brushless Motors

The development of these motors was to offer higher performance in smaller areas than that of DC brushed motors.

Besides, they are smaller than their AC models.

In the absence of flip rings or communicators, embedded controllers facilitate their operation.

Direct Drive Motors

These are highly efficient and low-wear systems that replace standard servo motors and their transmissions.

Besides, they accelerate quickly in addition to being easy to maintain for a longer duration.

Linear Motors

This motor features unrolled stator and motor that produce linear forces along the length of the device.

They contain flat and active sections containing two ends contrary to cylindrical models.

Besides, they are faster and accurate than rotatory motors.

Servo Motors

This motor has feedback sensors that enhance positioning, meaning servo motors provide the backbone of robotics.

Servo motors will use both linear and rotary actuators.

Cost-effective DC brushless motors are popular, but AC brushless motors are replacing them.

This is because they are suitable for high-performance applications.

DC Compound Motor

This is a hybrid between DC series and shunt motors containing shunts and field-like series.

Here, you can connect the stator and rotor via a winding compound of series and shunts.

To offer a small resistance path, you can design the series windings with fewer windings of wider copper wires.

Synchronous Motors

This motor works while relying on a 3-phase supply.

The stator will produce fields that rotate at stable speeds depending on the frequency of the AC.

DC Shunt Motor

This motor operates on DC and the armature windings and field windings connect in a parallel configuration called a shunt.

It is also known as a shunt wound DC motor and the winding type is called a shunt winding.

Induction Motor

This motor operates at asynchronous speeds.

It will use electromagnetic induction to alter the energy to mechanical from electric energy.

Hysteresis Motors

The rotor in this motor can induce hysteresis and eddy currents to produce the power it requires for the task.

They offer a smooth stable speed and low noise levels.

Stepper Motors

These motors apply internal rotors which you manipulate electronically using external magnets.

Besides, you can make the rotors using permanent magnets or soft metals.

The teeth of the rotors will align with the magnetic field of the magnets when you energize the windings.

This will enable them to move from one point to another in fixed increments.

Separately Excited Motors

Here, you will connect the stator and rotor using different power supplies.

This means you can control the motor from a shunt.

Also, you can straighten the armatures windings to produce flux.

Are Aluminum Motor Body Water And Corrosion Resistant?

Aluminum as a material will produce a thin layer of protective oxide that makes it corrosion resistant.

Also, it provides self-resistance to water and oxygen making them have water-resistant properties.

Besides, the surface treatments will enhance their resistance against corrosion and moisture.

What Are The Advantages Of Aluminum Motor Body Over Cast Iron Motor Body?

Cast iron motor body

Here are the benefits of an aluminum motor body over a cast iron motor body:

- The density of the aluminum motor body is lower than that of the cast iron motor body hence making the device lightweight

- The aluminum motor body has a better appearance effect than the cast iron motor body

- Resistance against moist and hot environments is higher in an aluminum motor body than in a cast iron motor body

- Heat dissipation of aluminum motor body is higher than that of cast iron motor body

- The aluminum motor body is non-magnetic making it suitable for electrical shielding

- Also, an aluminum motor body is non-sparking meaning it does not produce sparks when it contacts non-ferrous metals, or itself

Fully assembled aluminum motor body

Do You Manufacture OEM Aluminum Motor Body?

Yes.

We are an OEM manufacturer for aluminum motor body.

Depending on your requirements and specification, we can manufacture aluminum motor body according to your requirements and specifications.

What Is The Preferred Temper For Extruded Aluminum Motor Body?

The temper you can use for the extruded aluminum motor body includes the following:

- T4

- T5

- T6

How Much Does Aluminum Motor Body Cost?

The cost of an aluminum motor body varies a lot because of the following factors:

Configuration

Large aluminum motor bodies cost more than their smaller counterparts.

Quantity

Purchasing aluminum motor body in bulk will cost you less than purchasing them in small amounts over and over again.

Physical State

Brand new aluminum motor body costs more than a used aluminum motor body.

Discounts

Some manufacturers will offer you huge discounts during certain periods of the year.

Taking these factors into account, an aluminum motor body will cost you anywhere between 60 USD and 8000 USD.

What Is Your Lead Time For Aluminum Motor Body Manufacturing?

Our lead time for manufacturing aluminum motor body is between 20 days and 25 days once you make your order.

At Wellste, we ensure you get all aluminum motor body that meet high industry standards.

Contact us today for all your aluminum motor body needs.