- One-stop Design & Manufacturing Solutions

- Advanced Manufacturing Capabilities

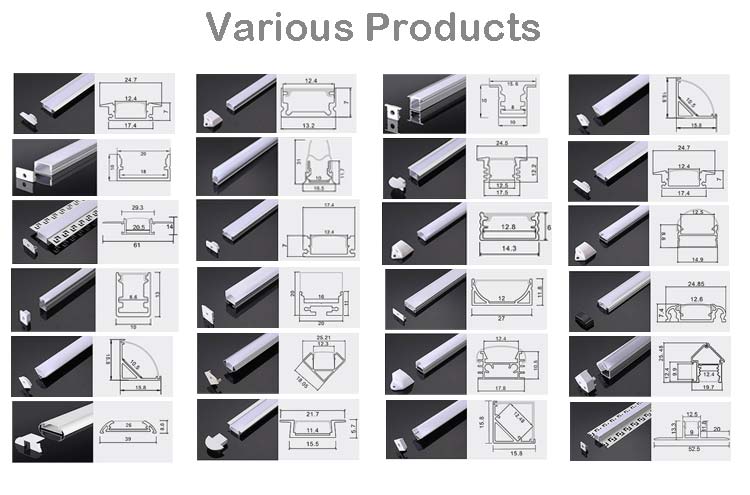

- Standard Existing Size save your initial cost

- Fast Shipment of Standard LED Aluminium Extrusion Size

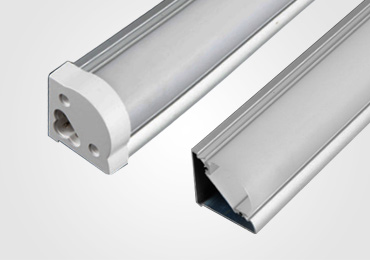

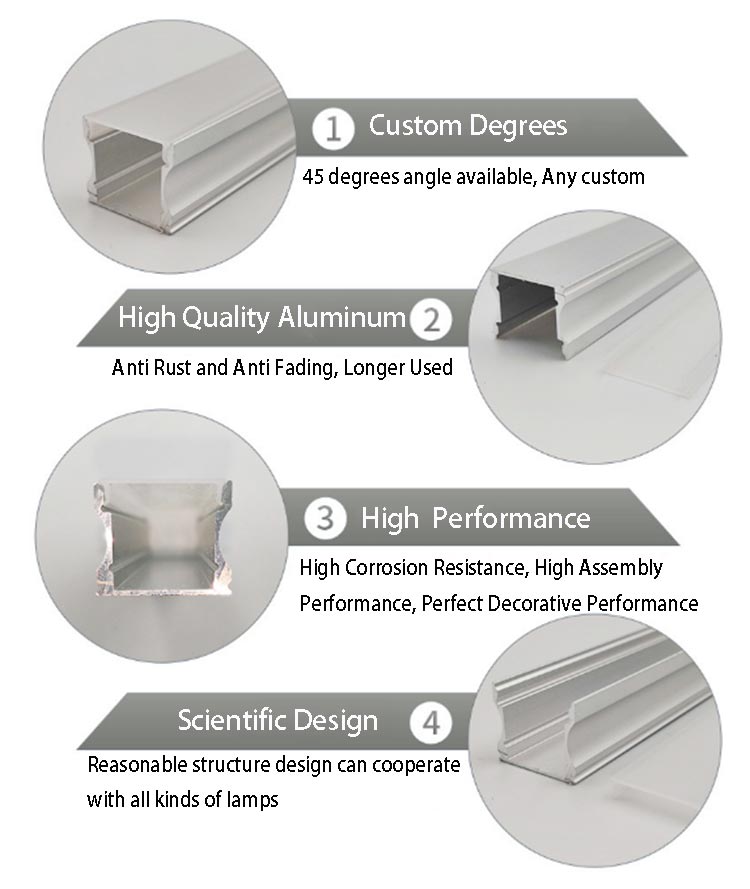

LED Aluminium Extrusion

Wellste offers LED aluminium extrusion that is constructed especially for stairs, floors, cabinets, closets, walls, and many more applications. It is made to be IP 67 waterproof, applicable for different outdoor lighting uses.

- Countless Available Molds

- One-stop purchasing system solution provides

- 100% Strict Quality Testing before loading

- One-stop Aluminium Extrusion Solution

Your Reliable LED Aluminium Extrusion Supplier and Manufacturer

Wellste LED aluminium extrusion, also named extruded led housing or led profiles, are guides or channels built to protect LED light strips. It is made from great quality aluminum, providing a modern and complete look for any lighting applications, such as commercial and residential lighting.

| Item Type | led aluminium extrusion |

| Material | 6000Series |

| Temper | T3-T8 |

| Finish | anodized silvery, or custom finishes |

| Length | 1m, 2m, 2.5m, 3m, customized length |

| Delivery time | 3~15 working days, or negotiated |

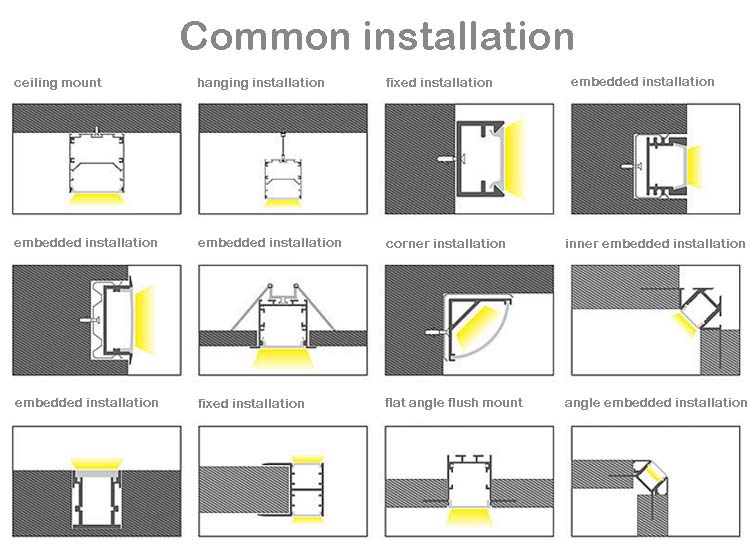

| Installation | Recessed / surface mounting |

| MOQ | 100 Meters |

| Application | home, shopping mall, factory, building etc |

| Packaging | standard export packaging or as discussed |

| Our Advantage | superior quality with competitive price, Certified enterprises in China |

- Production

- Description

- Projects

Being one of the top innovators worldwide, Wellste continuously producing the latest products which totally reach high expectations and the trust of our customers. We can guarantee a high-quality, UL and ETL listed LED aluminium extrusion for your business to expand faster.

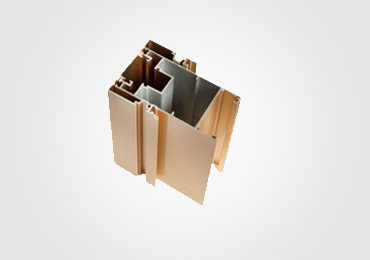

There are perfect finishes for LED aluminium extrusion that you can choose from. It`s either painted, anodized (inox, silver, black or gold), or wood-like finishes. All of them are available at Wellste for a friendly cost.

Wellste is capable of customizing the led aluminium extrusion type you need to complete your project. With our in-house electronic technicians, we can originate a play system and a simple plug which can help you save installation costs.

This offer is for you! The led aluminium extrusion from Wellste will certainly fit your preferences and liking. Even the most demanding client will be glad with the smart layout of our products.

Our range of LED aluminium extrusion is a significant part of any linear LED fixture. It acts as a lightweight, durable enclosure for LED strip lighting of any color, output, or color temperature. Most important of all, it acts as a leasing source of thermal control for LED strips.

In Wellste, there are plenty of styles, suitable for any lighting applications. Check us out!

Yes, Wellste is able to provide led aluminium extrusion for you to check the quality, Normally stock sample is for free for saving your cost, But it will require tooling cost if custom tube size.

It is only taking 7-10 days to complete your sample if the sample size is in stock. For custom led aluminium extrusion, It takes a little bit long time to make extrusion tooling, commonly it requires 30-35 days finish.

We have a personal paging service for helping customers’ solve queries Also, We have a free six months warranty. If our products occur quality problems, we will change the products.

We inspect the product after each manufacturing process and we have the advanced test facilities and instruments.

We are a manufacturer with OEM/ODM service.

Wellste: Your Best LED Aluminium Extrusion Manufacturer

Complete the look of your lights with Wellste LED aluminium extrusion! It has an incredible, very neat appearance for your lighting applications.

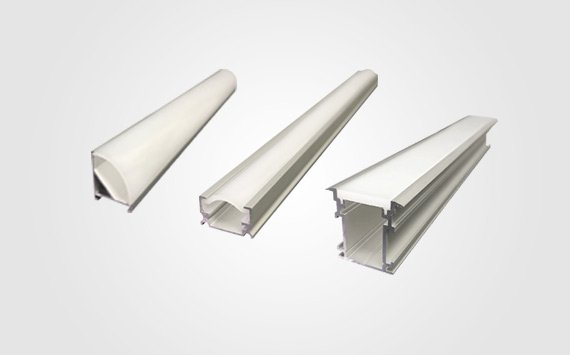

The LED aluminium extrusions we had are available in a variety of shapes and cuttable to different specific sizes. Suitable for applications like interior lighting, kitchen lighting, commercial lighting, architectural lighting design, and more.

Wellste has innumerable choices of LED aluminium extrusion. There are many sizes to select from. If it`s hard for you to choose what`s perfect for your applications, ask assistance from our sales staff.

Every LED aluminium extrusion has numerous characteristics, well-appreciated by both interior designers and regular customers. They can be easily fixed on the floors, corners, ceiling, or any places outside or inside of the building.

Enjoy the satisfying rays of light coming out from Wellste LED aluminium extrusions! Available finishes are available in wood-like, painted, or anodized (inox, silver, black, or gold). We can give you the exact finish of the LED aluminium extrusion you require.

Wellste is a top-leading supplier of LED aluminium extrusions for retail display, commercial lighting, residential lighting, and other lighting applications. For over 2 decades of technical expertise and our unique productions will definitely help your business achieve fast growth.

Wellste rich-experienced engineers can custom your own ideas regarding our products. One of our goals is to satisfy you. And as ISO9001-2001 certificated company, you can truly rely on us for a trouble-free aluminium fabrication.

Contact us to order.

LED Aluminum Extrusion: The Ultimate FAQ Guide

In this guide, you will find all information you need about LED aluminum extrusion.

Whether you want to learn about the designs, surface finish, properties or material grade – you will find all information right here.

What Is An LED Aluminum Extrusion?

LED aluminum extrusions are known by various names such as:

- LED aluminum profiles

- LED aluminum channels

LED Aluminum Extrusion

These extrusions will offer elegant and convenient methods of integrating various linear aluminum extrusion LED strip lights.

Also, the LED aluminum extrusions will protect and conceal the LED light strip.

Unlike traditional LED light fixtures, the LED aluminum extrusions offer design versatility.

It also has the benefit of being energy-efficient and offers heat dissipation from the LED light source.

How Many Variations Of LED Aluminum Extrusions Are Available In The Market?

LED aluminum extrusions are a common structure meaning they find their application in various areas.

This means you might be spoilt for choice when it comes to selecting the best LED aluminum extrusion suitable for you.

The most common types include the following:

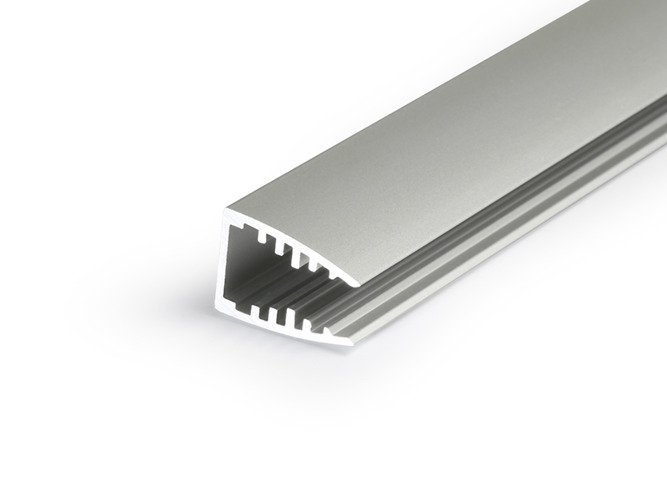

LED Aluminum Extrusion That Are Surface Mounted

These are by far the most popular variation of LED aluminum extrusions.

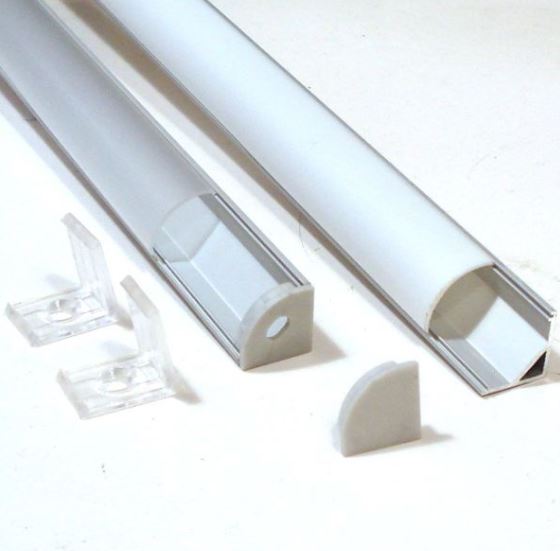

This surface mounted version comes with a variety of clips and end caps that make the mounting and installation process a breeze.

For general-purpose lighting, you can fix surface-mounted LED aluminum extrusions on different surfaces.

This includes ceilings, cabinets, kitchen cabinets, etc.

LED Aluminum Extrusion That Are Recessed Mounted

This type of LED aluminum profile is recessed within the surface providing a clean and subtle aesthetic.

Besides, you will mostly mount them on wooden surfaces such as cabinets and shelves.

Recessed mounted LED aluminum extrusions fit into the surface and not on top of the surface.

During installation, you need to have recesses on the surface that match the width of the structure.

Recessed Mounted LED Aluminum Extrusion

LED Aluminum Extrusion With A Corner Profile

This LED aluminum extrusion has perpendicular angles that can fit in corners.

Besides, you can mount the corner profile variation of LED aluminum extrusions in shelves, cabinets, stairs, etc.

LED Aluminum Extrusion For Drywalls

This type will offer a clean finish since the wires and strips will hide within the walls.

However, they are not that simple to install and may require a professional.

LED Aluminum Extrusion For Dry Walls

LED Aluminum Extrusions That Hang

This type of LED aluminum extrusion hangs from the ceiling with the help of a cable.

They are suitable for spaces with tall roofs so that the suspension will bring the light closer to the surface.

Ring Circular LED Aluminum Extrusion

This type of LED aluminum extrusion has a round shape and is mostly suspended from ceilings.

They are suitable for conference rooms, hotels, malls, etc.

Ring Circular LED Aluminum Extrusion

Wardrobe Rail LED Aluminum Extrusion

These LED aluminum extrusions find their application in closets.

LED Aluminum Extrusion That Are Flexible

This type of LED aluminum extrusion is made with a thin strip of aluminum hence, making them flexible.

They can create curved lighting on various curved surfaces.

In current lighting systems, you will find many aluminum extrusions LED strip.

LED Aluminum Extrusion For Architectural Buildings

This structure will sit within the structure of walls.

Cabinet And Furniture LED Aluminum Extrusion

This structure is suitable for use in furniture and cabinet lighting.

Magnetic Track LED Aluminum Extrusion

This structure makes use of magnets to install the LED aluminum extrusion.

Magnetic Track LED Aluminum Extrusion

LED Aluminum Extrusion For Skirting

This aluminum extrusion finds its application at the foot of walls.

Stairs And Inground LED Aluminum Extrusion

This structure offers a better seal cover and end caps since they protect the LED from environmental elements such as moisture.

Stairs LED Aluminum Extrusion

What Variations Of Diffusers Can You Install On And Use In LED Aluminum Extrusions?

There are various types of PC diffusers you can use with LED aluminum extrusions and will add an appeal to your lighting projects.

The types of PC diffusers you can use include the following:

Clear Dffuser

This type has a 95% transmittance rate and provides the most optimal light output.

Besides, this diffuser does not offer even light distribution in the LED aluminum extrusion.

Frosted Diffuser

The transmission rate of frosted diffusers is at 80%.

It is a popular type of diffuser for use in LED aluminum extrusions.

Frosted diffusers will also limit hotspots.

Opal Diffuser

The transmission rate of opal diffusers stands at 70%.

Opal diffusers have a coating that is milky white, meaning it will diffuse the light source from LEDs evenly.

Besides, they will also maximize hotspot reduction.

Opal Diffuser

Milky Diffuser

This type offers a 60% transmission rate and will eliminate hotspots.

Milky diffusers offer a small range of light output and for this reason, you need to use brighter versions of LEDs to combat this issue.

Black Diffuser

This type will provide a 40% transmission rate and completely hides the LED aluminum extrusion.

LED Aluminum Extrusion With smoke Black Diffuser

What Types Of Surface Finishes Can You Apply On Aluminium Extrusions For LED Lighting?

The main type of surface finish for LED aluminum extrusions is an anodized finish.

Anodization is an electrochemical process that will coat the metal with anodic oxide.

This layer makes the LED aluminum extrusion corrosion-resistant, decorative, and durable.

The other variations of surface finish you can use on LED aluminum extrusions for decoration and protection include the following:

- Paint

- Bright dipping

- Powder coating

Here are the common anodized finishes for LED aluminum extrusions:

Silver Anodized Finish

This type of finish has a transparent coating hence, the metallic look of the LED aluminum extrusion is visible.

Besides, the structure of the silver anodized finish gives off a metallic silver that contains minimal luster.

Sulphuric acid is the main element you will use to conduct silver anodized finish in LED aluminum extrusions.

White Anodized Finish

This type of anodized finish has a combination of silver anodizing and white color.

Besides, white anodized finish will protect the surface of the LED aluminum extrusion.

However, it makes the surface to become whiter compared to the metallic silver color common in aluminum metals.

This finish is suitable for white surfaces to offer a clean and seamless finish.

Black Anodized Finish

In this version, the LED aluminum extrusion contains a black pigment cover that anodizes the surface.

Also, you may use a black dye on the LED aluminum extrusion before you begin the anodization process.

This will make the color of the LED aluminum extrusion have various shades of black.

Black Anodized Finish on LED Aluminum Extrusion

What Kind Of Materials And Accessories Can You Use With LED Aluminum Extrusions?

There are additional accessories that you will use when making an LED aluminum extrusion.

There are other parts and materials that you will use to create the LED aluminum extrusion.

Here are the main materials you will find in LED aluminum extrusions:

PC Diffuser

These parts are made of polycarbonate material and they provide different levels of transmittance rate.

Low-quality polycarbonate over time will produce a yellow light effect.

Heat Sinks

These are important parts of LED aluminum extrusions since the LEDs will produce some form of heat.

The heat sinks are constructed with 6063-T5 aerial aluminum and they operate by transferring heat to the external environment.

Finned heat sinks are common since they offer a large surface area in LED aluminum extrusions.

End Caps

A majority of end caps are composed of plastic.

They will insulate the LED aluminum extrusions from openings and contain holes for wiring.

Besides, they seal the openings making it simple to replace the LED strips when the need arises.

Stainless Steel Clips

The mounting clips that you will find in LED aluminum extrusion come from stainless steel material.

The stainless steel clips will hold the LED aluminum extrusion on the surface where you are conducting the installation.

This makes installation easy as you only need to clip the LED aluminum extrusions in place.

Suspension Cable

These parts are important for hanging LED aluminum extrusions.

The suspension cable will attack the wall surface and then on the LED aluminum extrusion.

Besides, suspension cables are strong yet flexible, and the common material that makes them is stainless steel.

What Steps Should You Follow When Selecting LED Aluminum Extrusions?

Here are some steps to consider when buying the LED aluminum extrusions:

Dimension Of Aluminum Extrusion LED Strip

This is the most important thing to consider during the selection process.

The width is vital to consider besides the length which depends on your application requirement.

This is because you need to purchase the corresponding LED aluminum extrusions.

Lighting Effect

The type of LED aluminum extrusion and diffusers will depend on the lighting effect you want to achieve.

For instance, clear diffusers are suitable if you need to achieve more brightness.

Also, for decorative purposes, recessed or plastered-in LED aluminum extrusions are suitable.

Installation Location

Here, you will consider where you need to install the LED aluminum extrusion.

For instance, hanging LED aluminum extrusions are suitable if you do not require long aluminum extrusions.

Also, corner-mounted LED aluminum extrusions are suitable for closets.

Type Of Mounting Mechanism

Here, you will consider how you will mount the LED aluminum extrusion.

This entails answering questions related to recessed surfaces, plasterboard ceiling, etc.

What Are The Benefits Of Aluminium Extrusion LED Strip?

There are several benefits to using LED aluminum extrusions, and they include the following:

Enhancement Of Heat Dissipation

This is a more technical advantage that will save light and makes it suitable for use.

LED aluminum extrusions will expel more heat since they have large surface area because they are lengthy.

For this reason, the space within LED aluminum extrusions will have optimal temperatures during operation, thus LED lights will be durable.

Protects LED Light

When you place LED light strips bare, they become susceptible to damage from external elements.

Besides, waterproof LED light strips will not last that long.

LED aluminum extrusions protect the LED light strip from elements such as water, dust, etc.

Enhance Light Effect

When you use LED aluminum extrusions, the light effect within the area of installation will be enhanced.

Also, the area you are installing the LED aluminum extrusion will be attractive.

Diffusers on LED aluminum extrusions spread light more evenly and minimize heat spots.

The LED aluminum extrusions enhance lighting efficiency and occupy less space.

Besides, since LED aluminum extrusions are versatile, you can install them in several different spaces.

Ease Of Installation

The installation process of LED aluminum extrusions is simple and requires you to customize its length to fit during installation process.

All you need to do is drill mounting clips on location and screw the LED aluminum extrusion in place.

Another benefit is that you can mount LED aluminum extrusions in areas that lack electrical connections.

Numerous Applications

Depending on the type of LED aluminum extrusion, you can use it almost anywhere.

This includes areas such as bedrooms, cabinets, stairways, hallways, etc.

LED Aluminum Extrusion Enhances Light Effect and Can Be Used Anywhere

What Are The Properties Of Aluminum That Make Them Suitable For LED Aluminum Extrusion?

Aluminum is the most common metal you can use for extrusion.

Here are the properties making it suitable for making LED aluminum extrusions:

High Strength-to-Weight Ratio

Aluminum is light and strong hence can make durable LED aluminum extrusions.

Corrosion Resistance

Aluminum has a high corrosion resistance than most metals hence suitable for making LED aluminum extrusions.

Electrical Conductivity

Aluminum has suitable electrical conductivity hence you can use it over copper in certain usages.

Thermal Conductivity

Aluminum will conduct heat effectively hence suitable for making heatsinks in LED aluminum extrusions.

Ductility And Workability

This means you can form LED aluminum extrusions at room temperature.

Low-temperature Toughness

Aluminum maintains its tough nature in presence of low temperatures.

Resilience

Aluminum is tough hence can absorb sudden forces without much damage.

Non-magnetic

Aluminum is paramagnetic and not ferromagnetic, hence, will not gain a magnetic charge in the presence of strong magnetic fields.

Non-sparking

Aluminum will not produce sparks in its pure or alloyed state.

Reflectance

Aluminum has a high reflectance than any other metal within the range of 200 m and 400 mm.

Recyclability

Aluminum is easy to recycle and will not lose its properties.

Most Properties Of Aluminum Makes It Suitable In The Making Of LED Extrusions

What Factors Should You Consider In Aluminium Extrusions For LED Lighting?

These include the following:

Type Of Extrusion

Here, you will consider direct and indirect extrusion processes.

Extrusion Pressure

This pressure will overcome the pressure necessary to make the aluminum flow and overcome the friction between the billets and the die.

Type Of Die And Design

The diameter of the die will influence the mechanical working of the aluminum metal during extrusion.

Friction

To lower compression power and monitor metal flow, you need to minimize or eliminate friction.

Lubrication

This element is necessary for extruding high-strength LED aluminum extrusion alloys.

Alloy

Different alloys of aluminum need various extrusion parameters.

Temperature

A high temperature will promote metal flow that produces LED aluminum extrusions with no defects.

Extrusion Ratio

This is the ratio between the billet and the cross-section of the die opening.

A large extrusion ratio results in large deformation.

Extrusion Speed

Ensure you maintain the correct speed for the LED aluminum extrusion to have the right temperature.

Billet Length

The length of the billet will limit the extrusion ratio, length, and profile of the LED aluminum extrusion.

What Extrusion Processes Can You Use To Make LED Aluminum Extrusions?

These include the following:

Indirect Extrusion

In this process, you will press the die against the billet to form LED aluminum extrusions.

Direct Extrusion

In this technique, you will press the billet against the die to form LED aluminum extrusions.

Hydrostatic Extrusion

Here, you will use a form of working fluid that will force the billet to move through the die when forming LED aluminum extrusions.

Impact Extrusion

This process entails forming a metal slug within hollow shells to make LED aluminum extrusions.

Hot Extrusion

Here, you will conduct extrusion beyond the recrystallization temperature of aluminum where the microstructure starts to change.

Cold Extrusion

Here, you will conduct extrusion below the recrystallization temperature, basically at room temperature.

Also, you can classify the extrusion process depending on how the metal flows relative to the ram’s motion:

- Forward extrusion

- Backward extrusion

- Lateral extrusion

What Does Universal Micro LED Aluminum Extrusions Mean?

These are high-quality shallow housing suitable for hard or flexible LED strip lights that are between 8 mm and 10 mm wide.

How Can You Achieve Non-Spotting Finish When Using LED Aluminum Extrusions?

Here is an approach to buying LED aluminum extrusions parts that will assist you in achieving a non-spotting appearance:

Consider The Depth Of The Channels

As you are choosing your profile, the depth of the LED aluminum channel impacts the non-spotting finish.

A deeper channel makes more space for light to dissipate against diffusers.

Deeper diffusers affect the brightness of the light and the farther the LED is from the diffuser, the less bright the light will be.

Select The Correct Tape

LED tapes have several LEDs for every minute, hence select tapes with more LEDs per meter square to eliminate spotting.

Selecting A Suitable Diffuser

The diffuser you select will affect the spotting as different diffusers offer different transmittance rates.

How Can You Install LED Tapes Within LED Aluminum Extrusions?

LED tapes have adhesive backings that allow easy installation on LED aluminum extrusions.

All you need to do is remove the protective layer at the back of the LED light strip and press it firmly on the LED aluminum extrusion.

How Can You Achieve An IP65 Ingress Rating Within Aluminium Extrusions For LED Lighting?

Using an IP65 LED aluminum extrusion is necessary to ensure no leakages occur.

Ensure you use IP20 or even an IP65 tape inside the IP65 LED aluminum profile and do not use an IP65 tape inside IP20 LED aluminum extrusions.

Using an IP65 tape within the IP65 profile will cause moisture to enter the profile, causing condensation.

How Can You Install LED Aluminum Extrusions?

Here are some steps on installing LED aluminum extrusions:

- Start by taking the suitable LED aluminum extrusion for your application and insert a cap on one side of the structure

- Proceed by covering the top of the profile

- Take measurements on the LED aluminum extrusion then cut it to fit our application

- Connect LED light strip and connectors

- Remove taps from the LED light strips and fix on the LED aluminum extrusion without end caps

- Attach the wires from both ends and test the LED light strip

- Add end caps and fix the structure with mounting brackets on the surface of choice

Is It Possible For You To Cut LED Aluminum Extrusions To Any Length?

Yes, you can cut LED aluminum extrusions to fit your application.

How Can You Cut Aluminium Extrusions For LED Lighting?

The process entails the following:

- Slide LED covers in the LED aluminum extrusion

- Measure the LED aluminum extrusion to fit the application

- Place marks on the cut point

- Use a hand saw or a cutting machine to cut the profile

A Cutting Machine Used To Cut LED Aluminum Profile

What Quality Standards Should LED Aluminum Extrusions Conform To?

These include:

- CE mark of quality

- Restriction of Hazardous Substances [RoHS]

- ISO certification

- SGS certification

What Is The Warranty Of Aluminium Extrusion LED Strip?

LED aluminum extrusions have a warranty of 6 months.

What Inspection Processes Can You Conduct On LED Aluminum Extrusions?

The inspection techniques include the following:

Extrusion Materials Inspection

This inspection entails:

- Aluminum alloy check

- Extrusion dye check

- Additives check

Extrusion Visual Inspection

This inspection entails:

- Visual defects check

- Color and glossiness check

- Dimensional inspection

- Coating and finish check

- Extrusion dye check

- Weight and density check

Extrusion Performance Inspection

This inspection entails:

- Tensile strength

- Weldability check

- Workability test

- Corrosion test

- Flammability test

- Hardness test

- Weathering resistance test

- Abrasion resistance

- Chemical resistance

For any questions or inquiries about LED aluminum extrusion, contact us now.