Design phase communication

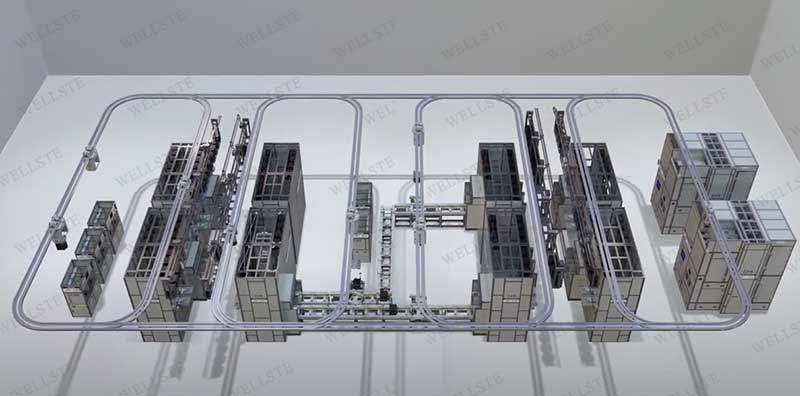

On 5th, December 2021, we received a new Extruded Aluminium Profile inquiry from a long-term cooperated customer in the mechanical automation industry.

The product is a new design that includes Curved and CNC processes, and they want Wellste to make this product for them, to improve their installation system, so better win a market share.

Technical negotiations

After receiving the drawings, our engineers had a careful evaluation of the drawings.

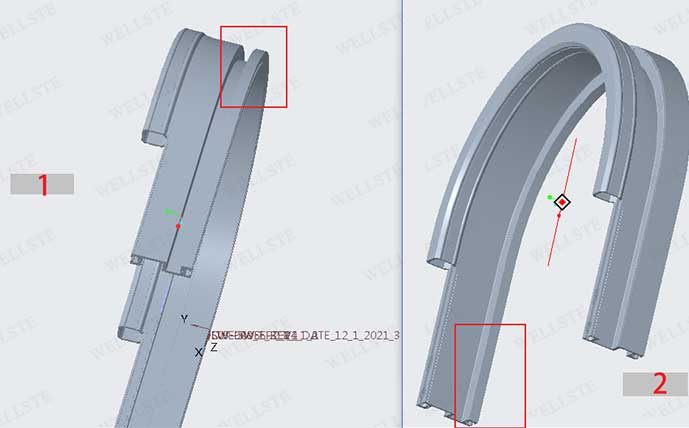

Can Wellste bend 180°aluminium extrusion?

The new inquiry has two Bending Aluminum Extrusion parts, which are inside and outside bending 180 (as shown in Figure 1),

The requests of the surface roughness are very high, roughness varies in different areas, with the smallest reaching 4μm.

The technical requirements were difficult, but finally, after a discussion with the technical team, we confirmed that we could prototype for the customer.

5th, January 2022 (after resuming work after the Chinese New Year), Wellste and the customer had a video conference, and both sides’ engineers had a deep discussion.

After technical issues exchange, we confirmed the following plan to start production.

Problems encountered production

How does Wellste make Aluminium Extrusion?

Production Process:

Making extrusion mold – Extrusion – Bending – Machining – Hard oxidation – Laser engraving

Product Information:

- Material:6063-T4;

- surface: natural hard oxidation 50μm;

- surface roughness: 0.4μm/0.8μm

2022.1.8-2022.1.21.

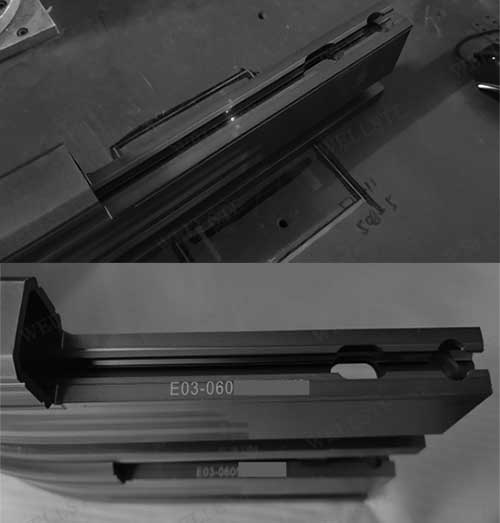

Completion of extrusion tool.

What is the best way to bend aluminium?

However, during the subsequent machining process, the stretch bending failed.

The engineer analyzed the reason: the section size of the profile was too large to use the traditional manual stretch bending.

2022.2.13

We informed the customer of the proofing situation and evaluated again. We decided to open two sets of bending dies and bend them by machine.

The cost of machine bending tooling is US$600/pcs, which is accepted by the customer.

How does Wellste bend aluminum 180 degrees?

2022.2.28

According to our engineer’s specific evaluation, the bending tooling finished the bending with such a large arc.

2022.3.18

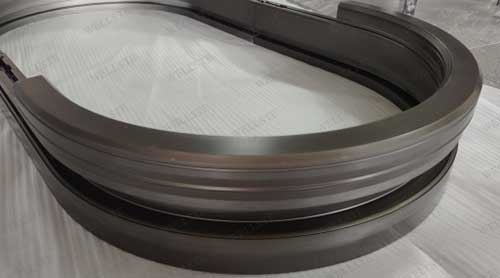

The bending aluminum extrusion part is completed, the following is the product bending effect which is 180-degree bending.

2022.3.20

After Hard oxidation,the whole anodized aluminum profiles is completed.

One solution to resolve the surface damage.

During the quality inspection, our inspector found damage and rough surface.

The technical analysis was that the internal stress of the product changed during bending and the profile was injured.

Our Engineer’s suggestion: the extrusion and bending time is too long, and the profile will become hard after being put in 6063-T4 condition for a long time,

so it is suggested to extrude quickly in 6063 T1 condition.

After informing the client, they agreed to change to 6063-T1.

2022.4.12

Wellste re-extrusion it, the custom aluminum extrusions is then bent again and hard-oxidized.

Laser Printing for the Bending Aluminum Extrusion

2022.4.28

Laser lettering completed.

Quality Test

How does Wellste ensure the products quality?

2022.5.1

Wellste general testing on dimensions surface, etc, And supply inspections and issues reports.

2022.5.20

The customer received the sample and the trial assembly was successful.

Sample Production

Any product, especially a new product design or any custom aluminum fabrication, is the result of continuous communication between our engineers and customers, and continuous improvement.

If you have any inquiries, please feel free to contact us at [email protected].