6061 aluminum alloy features high strength, hardness, good machinability, and ease of finish, so it is suitable for robust structural industry. This alloy’s heat conductivity is another advantageous trait, making it suitable for heat sinks and thermal management solutions.

6063 aluminum alloy is well-suited for a wide range of applications due to its excellent formability, high corrosion resistance, and superior heat conductivity. This alloy is often chosen for extrusion processes, making it an ideal choice for profiles and shapes. Additionally, 6063 aluminum exhibits good anodizing and finishing properties, allowing for customized surface treatments to meet specific design requirements.

In this article, Wellste gives you a detailed comparison between 6061 and 6063 aluminum alloy to help you quickly choose the aluminum grade that suits you.

Overview of 6061 and 6063 Aluminum alloy

6061 Aluminum alloy

6061 aluminum alloy is ideal for robust structural components. It has high strength and hardness, along with excellent machinability and surface treatment.

6061 aluminum also display good performance in load-bearing capacity and resistance to wind pressure.

6063 Aluminum Alloy

6063 aluminum alloy is one of the commonly used aluminum alloy types in doors and windows. It has excellent processing capabilities and corrosion resistance.

6061 VS 6063 Aluminum Alloy

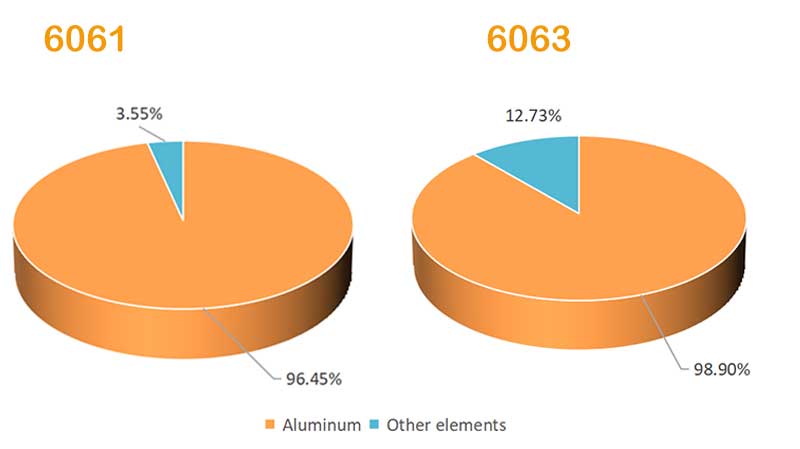

6061 and 6063 aluminum alloys differ in composition, mechanical properties, and applications. 6061 contains higher levels of other alloying elements.

It contains about 30-50% more magnesium and silicon than 6063. Regarding mechanical properties, 6061 alloy is stronger.

6061 aluminum suits high-performance applications, while 6063 is versatile for various uses.

Concerning Heat Treatment, 6061 aluminum exhibits a greater deformation coefficient and superior hardness compared to 6063 aluminum.

| 6061 VS 6063 Aluminum Properties | ||

| Properties | 6061 Aluminum | 6063 Aluminum |

| Density | Higher | Lower |

| Hardness | Higher | Lower |

| Strength | Higher | Lower |

| Durability | Good | Fair |

| Corrosion resistance | Good | Fair |

| Machinability | Good | Fair |

| Cost | Higher | Lower |

| Weldability | Good | Fair |

| Surface treatment | Good | Fair |

Density

6061 aluminum density is 2.75 g/cm³, 6063 aluminum density is 2.7 g/cm³, so 6061 slightly denser than 6063.

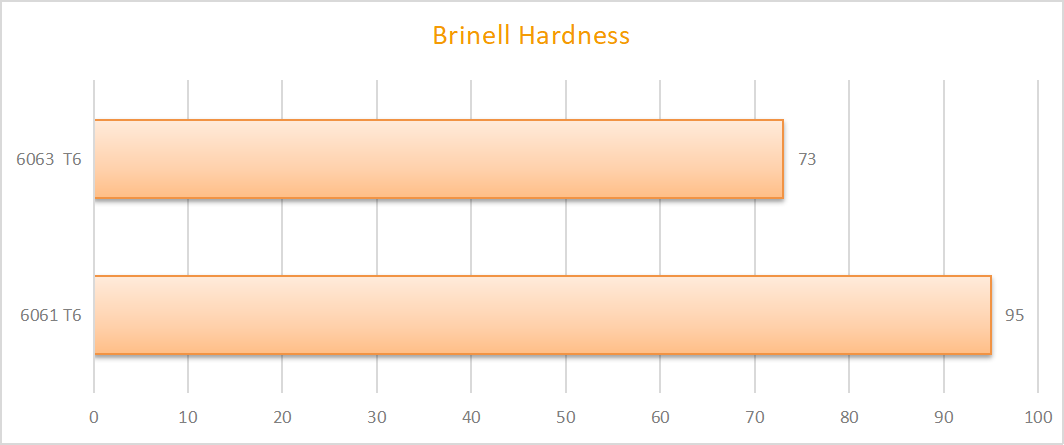

Hardness

Taking the T6 state as an example, 6061 T6 hardness is 95, and 6063 T6 hardness is 73. 6061 is harder than 6063.

1.3.3 Strength

As to tensile and yield strength, 6061 is better than 6063.

1.3.4 Durability

6061 aluminum alloy is harder and stronger than 6063, so 6061 aluminum alloy is more durable.

1.3.5 Corrosion Resistance

Without anodizing, 6061 aluminum corrosion resistance is better than 6063 aluminum alloy.

1.3.6 Machinability

6061 aluminum machinability is good than that of 6063.

1.3.7 Weldability

6061 aluminum weldability is also better than 6063.

1.3.8 Surface treatment

Both 6061 and 6063 have good oxidation properties. 6063 aluminum alloy surface adhesion is good than 6061, so it has extremely strong oxidation ability.

1.3.9 Cost

Due to its high strength and excellent properties, 6061 aluminum cost is more expensive than 6063.

1.3.10 Applications

Aluminium alloy 6063 applications: Aluminum Handrail and Fence Extrusions, Aluminum Cabinet Frame Extrusions, Boat Windshield Frame Extrusions, and architectural aluminum extrusions.

6061 aluminum applications: trucks, tower buildings, ships, trams, furniture, mechanical parts, precision processing, etc.

2. 6061 VS 6063 Aluminum: Alloy Series and Chemical Composition

6063 aluminum alloy contains 0.4% Si and 0.7% Mg. Its hard material strength is 295 MPa, soft material strength is 111 MPa.

Its applications are tubular railings, furniture, frames, and construction extrusions.

6061 aluminum alloy contains 0.6% Mg, 0.25% Cu, and 0.09% Cr. Its hard material strength is 316 MPa, soft material strength of 127 MPa.

Its uses include construction, furniture, transport, and more.

| 6061 VS 6063 Aluminum Composition | ||

| Element | 6061 Aluminum % | 6063 Aluminum % |

| Aluminum | 96.45 | 98.9 |

| Copper | 0.15-0.4 | ≤0.1 |

| Fe | ≤0.7 | ≤0.35 |

| Magnesium,Mg | 0.8-1.2 | 0.45-0.90 |

| Manganese,Mn | ≤0.15 | ≤0.1 |

| Silicon,Si | 0.4-0.8 | 0.2-0.6 |

| Titanium,Ti | ≤0.15 | ≤0.1 |

| Zinc,Zn | ≤0.25 | ≤0.1 |

| Chromium,Cr | 0.04-0.35 | ≤0.1 |

| Other each | ≤0.05 | ≤0.05 |

| Other total | ≤0.15 | ≤0.15 |

2.1 6061 Aluminum Composition

Since Mg and Si content is higher than 6063, 6061 has more strength and corrosion resistance.

2.2 6063 Aluminum Composition

Since higher Si and Mn, 6063 alloy extrudability and finish are better.

2.3 6061 VS 6063 Aluminum Composition

6061 and 6063 have different chemical compositions.

6061 known for its high toughness, excellent machinability, and corrosion resistance. It finds applications in heavy-duty vehicles, aerospace, electronics, furniture, etc.

6063 offers high strength and is easy to weld, suitable for architectural materials like doors, windows, curtain walls, and indoor or outdoor.

3. 6061 VS 6063 Aluminum: Mechanical Properties

3.1 6061 Mechanical Properties

6061 aluminum alloy is known for its excellent processability. Notable welding characteristics, strong corrosion resistance, high toughness, and so on.

3.1 6063 Mechanical Properties

6063 aluminum profiles excel in plasticity compared to 6061. They allow the material to achieve the desired precision.

3.1 6061 VS 6063 Mechanical Properties

The following chart is a detailed comparison of 6061 and 6063:

| 6061 VS 6063 Aluminum Mechanical Properties | ||||

| 6061 Aluminum | 6063 Aluminum | |||

| Mechanical Properties | 6061 T4 | 6061 T6 | 6063 T4 | 6063 T6 |

| Fatigue Strength | 96.5MPa/14000 psi | 97MPa/14000 psi | 68.9 MPa/10000 psi | 68.9 MPa//10000 psi |

| Tensile Strength | 35000 psi | 310MPa/45000 psi | 25000 psi | 241 MPa/35000 psi |

| Yield Strength | 21000 psi | 276MPa/40000 psi | 13000 psi | 214 MPa/31000 psi |

| Brinell Hardness | 65 | 95 | 46 | 73 |

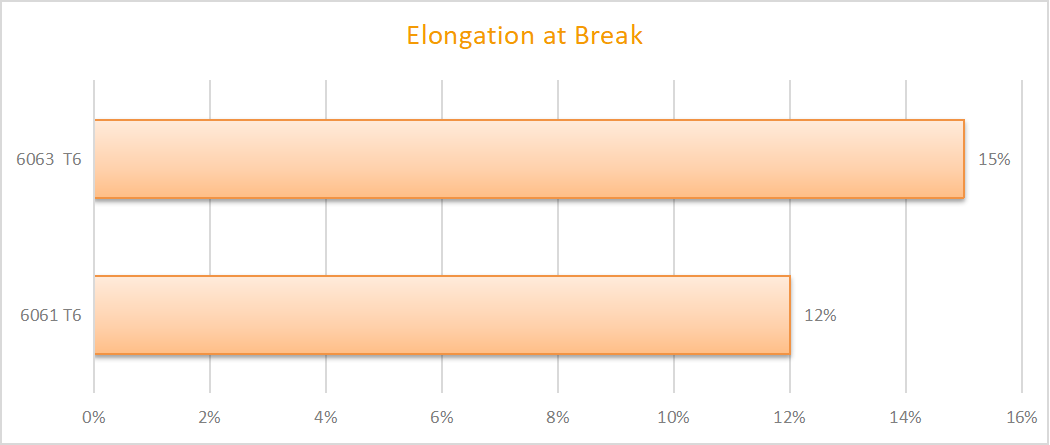

| Elongation at Break | 16% | 12% | 22% | 15% |

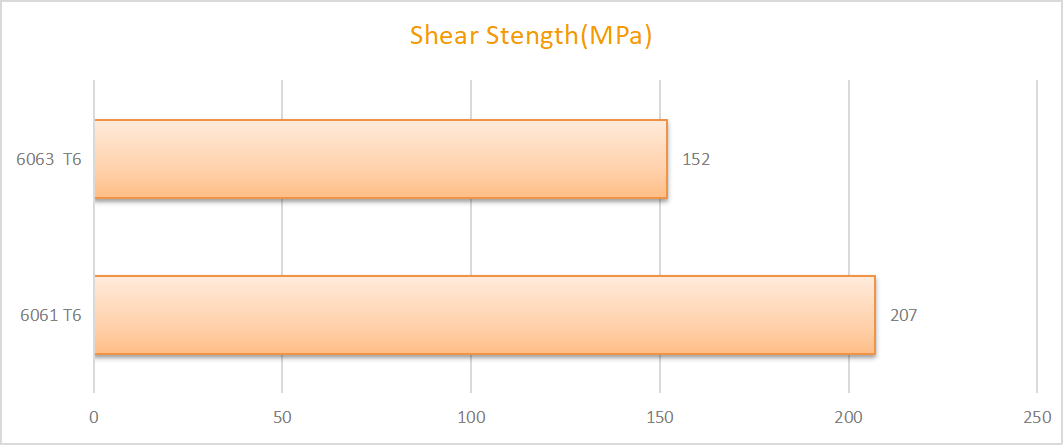

| Shear Stength | 24000 ksi | 207 MPa/30000 ksi | 16000 ksi | 152MPa/22000 ksi |

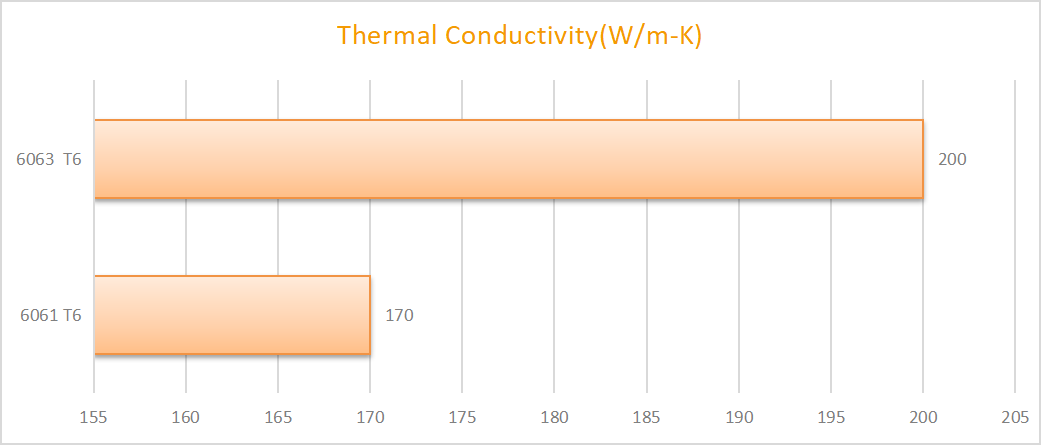

| Thermal Conductivity | 154 W/m-K | 170W/m-K | 200 W/m-K | 200 W/m-K |

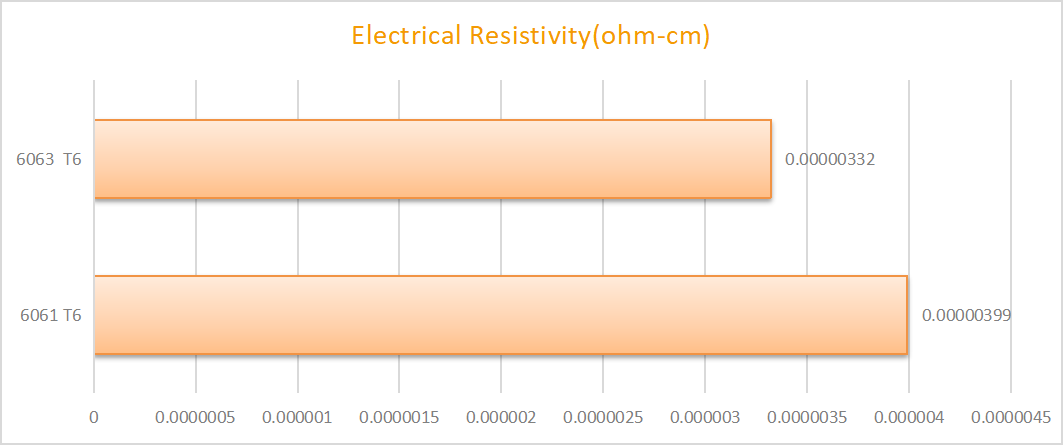

| Electrical Resistivity | 4.32e-006 ohm-cm | 3.99e-006 ohm-cm | 3.3e-006 ohm-cm | 3.32e-006 ohm-cm |

| Modulus of Elasticity | 10000 ksi | 68.9 GPa/10000 ksi | 10000 ksi | 68.9 GPa/10000 ksi |

| Melting Point | 582 – 652 °C | 582 – 651.7 °C | 616 – 654 °C | 616 – 654 °C |

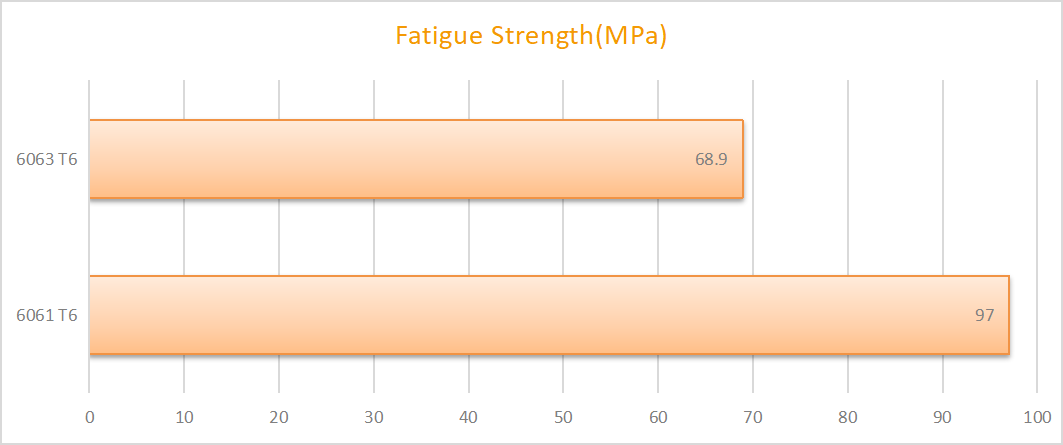

3.1.1 Fatigue Strength

6061 aluminum fatigue strength is slightly higher than 6063.

6061 aluminum alloy common in the T6 state, and its fatigue strength is approximately around 97 MPa. On the other hand, 6063 aluminum alloy fatigue strength is 69 MPa.

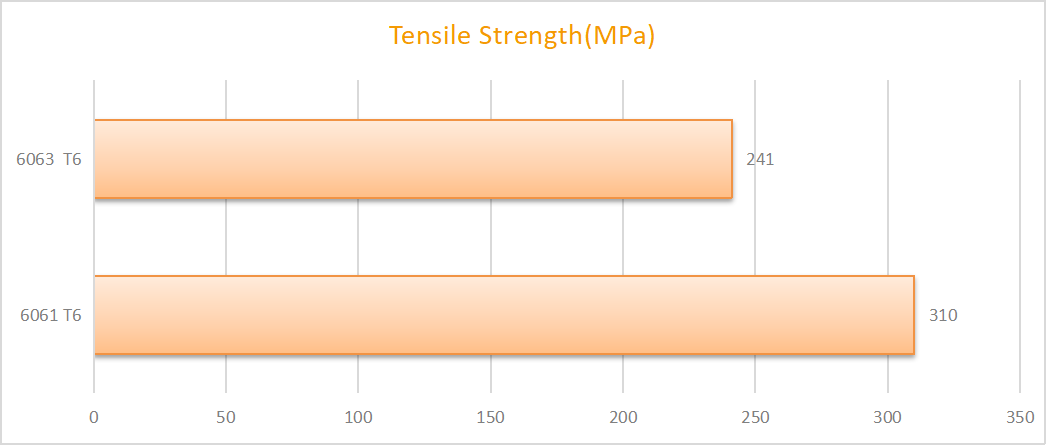

3.1.2 Tensile strength

6061 aluminum tensile strength is higher. In the T6 state, its tensile strength is about 310MPa.

On the other hand, 6063 aluminum tensile strength is lower, around 241MPa in the T6 state.

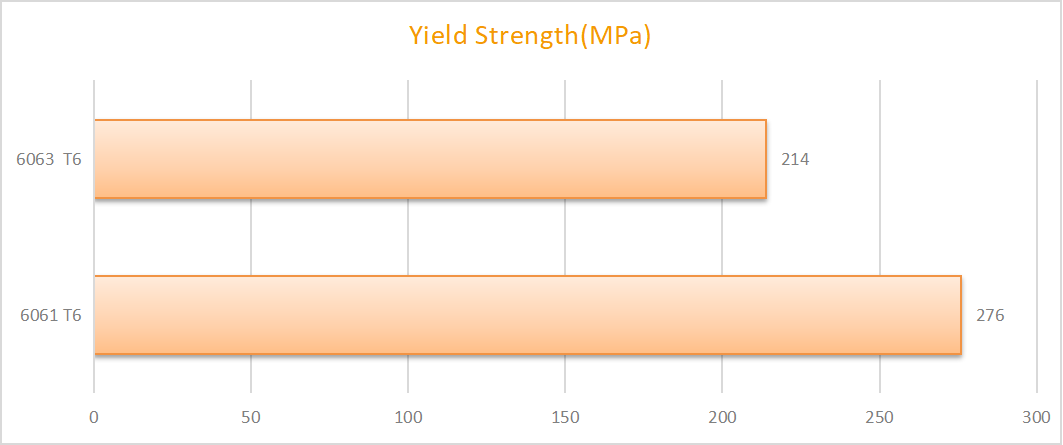

3.1.3 Yield strength

6061 aluminum yield strength is about 276MPa in the T6 state.

On the other hand,6063 aluminum yield strength is a lower, approximately 214MPa in the T6 state.

Therefore, 6063 is relatively softer and more prone to deformation.

3.1.4 Brinell Hardness

6061 T6 aluminum Brinell Hardness is 95, while 6063 T6 is 73. The lower hardness makes 6063 easier to machine than 6061.

3.1.5 Elongation at Break

6063 aluminum elongation at Break is 15%, 6061 aluminum Elongation at Break is 12%, which means 6063 has a stronger ability to withstand pressure.

3.1.6 Shear Strength

6063 T6 aluminum Shear Strength is 152MPa, and 6061 T6 aluminum Shear Strength is 207MPa. So 6063 can withstand greater shear forces.

3.1.7 Thermal Conductivity

6061 T6 aluminum thermal conductivity is 170W/m-K, and 6063 aluminum thermal conductivity is 200W/m-K. Therefore, 6063 is more suitable as a heat dissipation material.

3.1.8 Electrical Resistivity

Both 6061 and 6063 are electrical conductors. In comparison, 6063 has the lowest resistivity, 6061 Electrical Properties is higher, so 6063 has better conductivity.

3.1.9 Modulus of Elasticity

6061 and 6063 aluminum modulus of elasticity is the same, so they are comparable in terms of elasticity.

3.1.10 Melting Point

6061 aluminum melting point is 582 – 651.7°C, 6063 aluminum melting point is 616 – 654°C. 6061 is slightly lower and it has more resistant to high temperatures.

For more details about aluminum melting point, refer to this article: Aluminum Melting Point – The Ultimate Guide For Optimal Castings.

4.Tips on choosing the right alloy for your project

4.1 Determine Your Applications

6063 and 6061 aluminum alloys provide flexibility in their usage, choose which one depends on the material performance.

Here are Wellste recommendations for your consideration.

| 6061 Aluminum Applications | ||

| Industry | Feature | Applications |

| Ship parts | Good corrosion resistance and machinability | Hull structures, decks and other parts of ships |

| Aircraft parts | Good machinability and strength | Structural components, engine components and other parts of aircraft |

| Bicycle frame | Good machinability and light weight | Bicycle frames and other components |

| Electronic devices | Good electrical conductivity and machinability | Electronic device casings and heatsinks |

| 6063 Aluminum Applications | ||

| Industry | Feature | Applications |

| Construction | High strength and Good corrosion resistance | Windows&Door, door handles, curtain walls, handrial, etc |

| Cars and motorcycles | Light weight | Car door frames, roof racks, seat frames, etc |

| Electronic | Thermal Conductivity | Electronic equipment enclosures, heat sinks and electronic cables |

| Decoration and homewares | Common features | Decorative items, furniture, lighting accessories,etc |

4.2 Consider The Budget And Availability

6063 alloy is common, so the MOQ requirement is relatively small and the price is cheaper than 6061.

4.3 Evaluate Machinability

6061 vs 6063 machinability: 6061 aluminum alloy has slightly better machinability compared to 6063. It exhibits higher mechanical performance, including higher hardness, making it more common in applications that require high mechanical strength.

6061 vs 6063 welding: 6063 aluminum alloy has relatively better weldability. It has higher plasticity and is more suitable for various types of welding, including TIG welding and argon arc welding. In contrast, the welding performance of 6061 may be somewhat inferior.

6061 vs 6063 bending: 6063 aluminum alloy has better formability, making it easier for stamping, bending, and shaping operations. Therefore, it is more popular in applications requiring complex shapes.

6061 vs 6063 aluminum corrosion resistance: Both 6061 and 6063 have good corrosion resistance, but in some cases, 6061 may be slightly superior to 6063.

Therefore, if your application requires higher mechanical strength and hardness, or need machining operations, 6061 may be more suitable.

However, if you prioritize formability, and specific appearance requirements, then 6063 may be a better choice.

4.4 Evaluate Heat Treatability.

Both 6061 and 6063 are heat-treatable alloys, and different heat treatment states result in varying mechanical properties.

| 6061 VS 6063 Aluminum Tempers | |

| Grades | Tempers |

| 6061 | F,O,T4,T451,T42,T5,T6,T651,T6511,H112 |

| 6063 | O,T1,T4,T5,T6,T83,T831,T832,T835 |

It’s important to choose the heat treatment state that best suits your hardness requirements.

4.5 Consider Your Surface Treatment

6061 resists corrosion and easily anodized than 6063, making it an ideal choice for many industries.

4.6 Check For Industry Or Regulatory Standards

If you are not sure, you can consult industry standard documents, different product types will have the most suitable material requirements

4.7 Consult With An Expert Or Supplier

You can also consult industry experts. They will recommend suitable aluminum grades for you based on their experience.

5. Conclusion

In summary, both 6061 and 6063 have excellent properties suitable for different applications.

6061 Aluminum Alloy:

- Offers higher mechanical performance with typically higher tensile and yield strength.

- Use for requiring higher mechanical strength applications.

- Has relatively poorer welding performance.

- For applications requiring higher hardness and strength, such as aerospace and automotive components.

- Suitable applications need high mechanical performance.

6063 Aluminum Alloy:

- Demonstrates good machinability and is easy to stamp, bend, and shape.

- Has good welding performance and is suitable for various welding types.

- 6063 is suitable for applications requiring complex shapes and appearances, such as construction, decoration, windows, and door frames.

- Suitable applications need good machinability and appearance.

If there is a need for increased mechanical strength and hardness, especially in industrial settings, 6061 is an appropriate choice.

If good machinability, welding performance, and appearance are important, or for applications in construction, decoration, 6063 is a good option.

Wellste is a manufacturer specializing in extruded aluminum profiles. We provide a variety of different grades of aluminum alloy materials to meet various customer requirements. Common grades include 6061, 6063, 7075, 7005, 5086, 5082, 2024, etc. For details about the aluminum grade, recommend you refer to our complete article: Aluminum Grades Unveiled: Selecting the Perfect Match for Your Project.

Wellste can customize different grades of aluminum profiles according to customers’ specific requirements. These aluminum profiles meet industry standards, are of high quality and competitively priced, and are suitable for various applications. In addition, we also provide one-stop processing services to meet your product machining needs.

Whether you need custom aluminum extrusion or custom aluminum fabrication, Wellste can provide you with a satisfactory solution.

Useful documents downloads:

6061 VS 6063 Aluminum Properties

6061 VS 6063 Aluminum Composition