- Advanced Manufacturing Capabilities

- One-stop Design & Manufacturing Solutions

- Standard Existing Size Save Your Initial Cost

- Fast Shipment with a full range of Stock Products

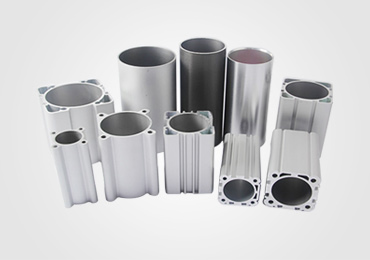

Aluminum Moulding Profiles

Wellste aluminum moulding profiles offer broad choices of standard shapes and sizes. As a matter of fact, Wellste has 2000 tooling sets of standard designs.

- Accepts Drawings of Your Required Design

- Comprehensive List of Available Standard Shapes

- Weekly Update on each Step of the Production Process

- In-house Chemical and Mechanical Testing for Assured Quality

The Professional Aluminum Moulding Profile Supplier

Wellste offers one-stop machining services aluminum moulding profiles that will help you save more. Drilling, punching, milling, CNC machining, welding, and many more are readily available.

| Item Type | Aluminum Moulding Profiles |

| Material | 1000series ~ 7000series aluminium |

| Temper | T3-T8 |

| Thickness | 0.3–50m |

| Color | Silver white, bronze, gold, black, champagne, customized |

| Shape | customized |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| Length | customized length |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Deep process | CNC, drilling, milling, cutting, stamping, welding, bending, assembling, Custom Aluminum Fabrication |

| MOQ | Low MOQ |

| OEM & ODM | Available. our engineer can check and discuss your design, great help! |

| Free Samples | Yes, we can provide free sample |

| Delivery time | 15-20 days after sample confirmed & down payment, or negotiated |

| Port | Shanghai Port |

Wellste aluminum moulding profiles surface finishes include anodize, powder coating, and PVDF coating. These surface finishes make the aluminum moulding profiles more corrosion-resistant and highly attractive.

Do not delay sending us your drawings or just a rough sketch. We will keep you updated on every step of the production process each week.

Send us a message for a quote today. Our customer service is available 24/7 to answer all your questions.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

We always supply a pre-production Aluminum Moulding Profiles sample before mass production; and we always have final Inspection before shipment;

We are a manufacturer with OEM/ODM service.

Yes, Wellste is pleased to provide Aluminum Moulding Profiles for you check quality, Normally sample is for free for saving your cost, But it will require tooling cost if custom size.

It only takes 5-7 days to complete your order if the Aluminum Moulding Profiles size is in stock. For Aluminum Moulding Profiles, It takes a little bit long time to make extrusion tooling, commonly it totally requires 25-30 days to finish production.

We provide Low MOQ for Aluminum Moulding Profiles. 1pc sample is free for you to check our quality.

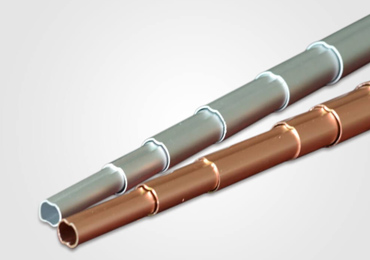

Products You May Looking for

Wellste: Your Premier aluminum moulding profiles Supplier and Manufacturer

Wellste engineers will help you find what aluminum moulding profiles you require. Just send us your designed requirement, and we are capable of finding the best-suited aluminum moulding profiles.

Wellste aluminum moulding profiles are available on our standard shapes, it will reduce your tooling cost.

Moreover, it will speed up the production process of your aluminum moulding profiles.

Wellste aluminum moulding profiles indeed bring many benefits regarding production capabilities.

Before extrusion, the material used for your aluminum moulding profiles passes chemical composition testing. This process is to make sure that the materials we are using are free from impurities.

As a result, Wellste aluminum moulding profiles can truly perform to their maximum capacity. Wellste aluminum moulding profiles have ensured reliability you can trust.

Wellste aluminum moulding profiles stand out, may it be in strength or aesthetics.

Each Wellste aluminum moulding profiles is composed of high-grade material with ensured quality.

Likewise, Wellste aluminum moulding profiles are also mechanically tested by our skilled technicians.

There are a lot of choices of material you can pick to build your aluminum moulding profiles. Depending on your needs, you can choose from 3000, 5000, 6000, to 7000 aluminum series.

For details, the 3000 series brings high strength to your aluminum moulding profiles. Despite its high strength, the 3000 series still features excellent molding.

More so, the 3000 aluminum series is easy to weld and has great corrosion resistance. It also gives Wellste aluminum moulding profiles heat treatment which results in better strength.

The 5000 aluminum series is very resistant to corrosion and rust. Some of its primary features include a high strength-to-weight ratio, great tensile strength, and capable of high elongation.

However, 5000 series alloy has good welding ability and wear resistance.

Next, the most widely used series is the 6000 series alloy. This material offers Wellste aluminum moulding profiles with proven corrosion resistance and oxidation resistance.

Wellste aluminum moulding profiles out of 6000 series alloy are best suited for structural support.

Lastly, the 7000 series alloy is the strongest on the list. It contributes to the wear resistance and welding ability of aluminum moulding profiles.

The only downside of 7000 series alloy is its poor corrosion resistance. Yet, it features heat treatment to give your aluminum moulding profiles extra durability.

Also, Wellste aluminum moulding profiles are capable of various surface treatments.

Wellste is your trusted companion when it comes to the design and manufacturing process. You can simply send us your ideas or drawings.

Our highly capable engineers will take your sent designs as a basis or even suggest some improvements.