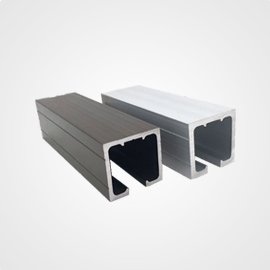

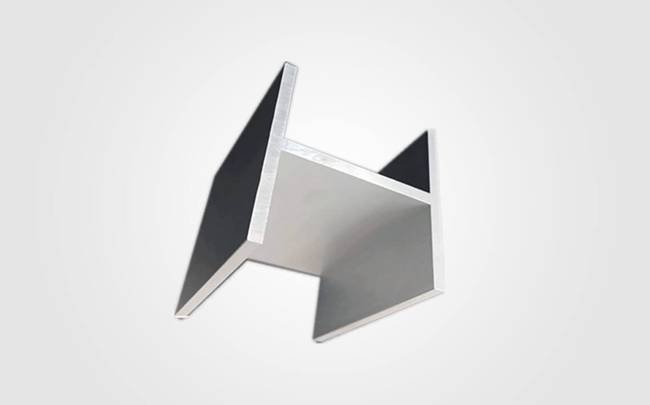

Aluminum I Beam

- Advanced in-house Quality Testing Lab

- Design & Customize your Aluminum I Beam

- Comply with GB/T 6892 Standard Requirements

- 6063,6061 Alloy No, Other special alloys upon request

Features For Aluminum I Beam

The strength of aluminum I beam is quite strong strength, so it is used to provide lightweight structural support for structures such as raceways and framework. These types of beams are also diversely used to provide support to buildings and enclosures.

Lightweight

High Strength

Corrosion Resistance

Ease of Fabrication

Excellent Thermal and Electrical Conductivity

Dimensional Stability and Durability

Size Range

Height

20-500mm

(0.79in-20in)

Width

10-300mm

(0.39in-11.81in)

Wall Thickness

1.5-50mm

(0.06in-2in)

Length

6-12m

(19.7ft-39.4ft ),Customized

Typical Alloy

Wellste Aluminum I beam made from 6061 aluminum alloy, is one of the most popular choices among our customers as it is quite easy to cut, form, weld and even machine.

2000 series

2024

5000 series

5052, 5083 etc

6000 series

6061, 6063, 6082 etc

7000 series

7075 etc

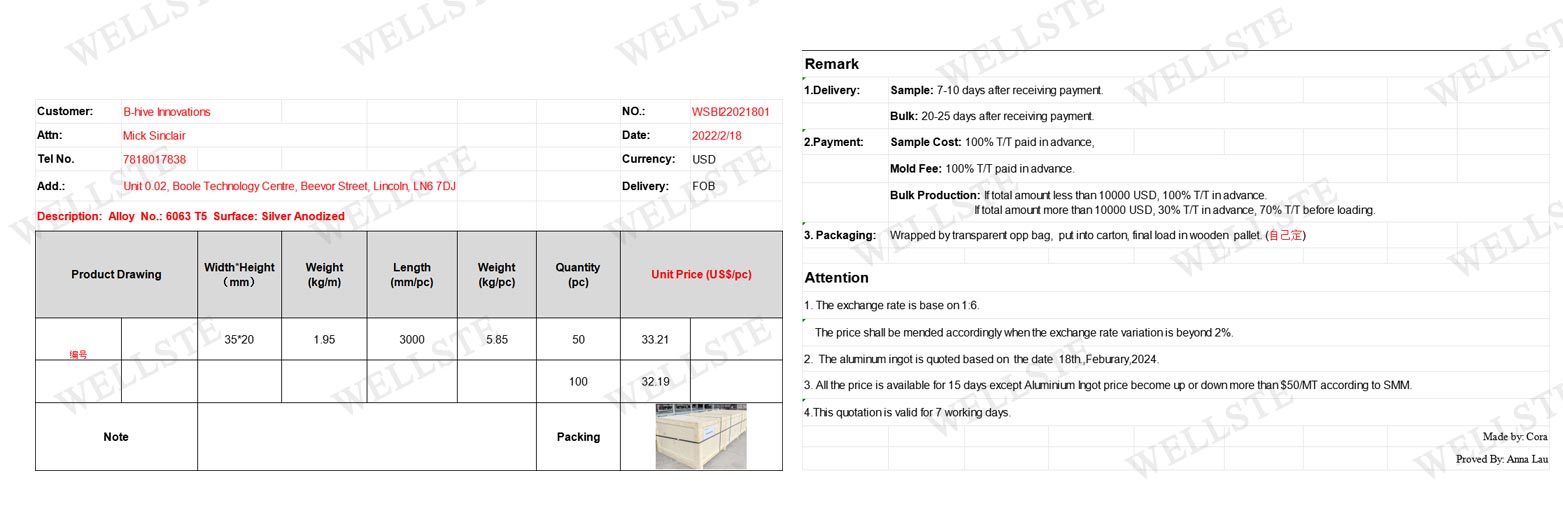

Send your inquiry Now!

Wellste’s customers have an additional advantage of getting a 24/7 fast response, regarding the design and manufacture of the aluminum I beam. Feel free to contact Wellste sales engineer and get your free quote today.

Wellste Aluminum I beam are professionally manufactured and supplied to our customers only after extensive quality assurance. They have been carefully tested by in-house tests and approved only after extensive quality control. Wellste provides In-house Strictly Testing Lab for 6-step internal inspection.

Wellste Aluminum I Beam is our product that is manufactured and supplied to a large number of customers. It is often treated as structural aluminum beams. Most commonly, we use certified 6061 aluminum alloy. This aluminum I beams are only ready for supply after they have been carefully monitored and tested at in-house labs, with special emphasis to quality control. This ensures you can get a strong aluminum I beam but with lightweight aluminum h section.

Wellste Aluminum I beam can meet American standard in the market. When you are ordering your aluminum I beam, you can choose the specific size and design from a wide range of options available. We own plenty of molds in standard size. This will facilitate you in making a choice that is according to your cost budget. In addition, Wellste is also able to customize your own design. Load capacity can be calculated based on some dimensions and specifications. Finally, you can figure out the maximum loading capacity of the aluminum I beam.

| Product name | Aluminum I-Beam |

| Description | Aluminum I-Beam is a kind of aluminum profile with I-shaped cross-section.It is favored for its light weight, high strength and corrosion resistance. |

| Material | aluminum alloy 6061, 6063, 2024, 5052,5083, 7075, etc. |

| Temper | T5, T6, etc. |

| Finish & Color | anodizing, powder coating, sandblasting anodizing, brushed anodizing, etc. |

| Height | 20-500mm(0.787in-1ft 7.685in) |

| Airfoil Width | 10-300mm(0.39in-11.81in) |

| Wall Thickness | 1.5-50mm(0.059in-1.968in) |

| Length | 6-12m(19ft 8.22in-39ft 4.44in),Customized |

| Packing | wooden frame, plywood case, shrink film. |

| Application | Aluminum i beam is widely used in the fields of construction, industrial machinery, transportation, etc. |

Standard Packing Option

* Long bar length profiles 3.0-6.0 meters*

Protective Film

Shrink Sleeve

Brown Paper

Brown Paper

* Short bar length profiles 0.3-3.0 meters*

EPE Foam

Poly Bag

Wooden Crate

Wooden Case

-Loading & Shipment-

Pallet Loading

Bulk Loading

LCL Loading

Expedited Express

Mold Design

1100T Extrusion line

3600T Extrusion Line

Hanging Aluminum Extrusions

Horizontal Powder Coated

CNC workshop

Punching Equipments

Inspection Lab

Wellste: Your Top Aluminum I Beam Supplier

Wellste Aluminum I beam are professionally manufactured and supplied to our customers only after extensive quality assurance. They have been carefully tested by in-house tests and approved only after extensive quality control. Wellste provides In-house Strictly Testing Lab for 6-step internal inspection.

Wellste Aluminum I beam surface are usually mill finish. However, in some cases where the aluminium I beam has to be exposed to extreme weather conditions or has to endure a corrosive environment, likes marine situation, the process of mill finish alone cannot protect it. Anodizing is a must and perfect solution available at Wellste. After a carefully monitored anodizing process, we can get aluminum I beam with better corrosion resistance.

What’s more, Wellste offers fast and friendly customer service. The foremost goal and rigid pursue of Wellste is to ensure customer satisfaction and the common development with our customers.

Get a free quote in 8 hours!

Manufacture in Technology

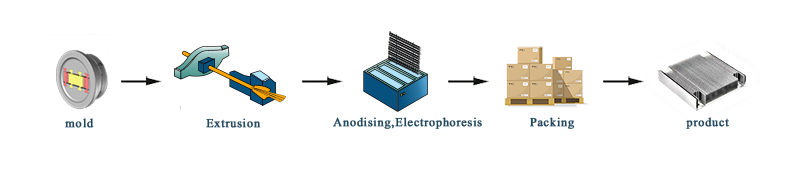

Extruded

Extrusion is the most commonly used process for the manufacture of I-beams and is particularly suitable for the production of small and medium-sized I-beams (usually with a width of 50mm – 500mm).

step1

Mold Design

step2

Aluminum billet heating

step3

Extrusion Molding

step4

Cooling and stretch straightening

step5

Cutting & Finishing

heat treatment

Heat treatment is used to increase the strength and hardness of aluminum alloys, especially the 6XXX and 7XXX series. Common treatments are T5 and T6, T5 is used for alloys such as 6063 to improve strength, T6 is used for 6061 alloys for higher strength and hardness.

T6 is commonly used for alloys such as 6061 to provide higher strength and hardness.

Welding

For larger I-beams (e.g. > 500mm wide), they may need to be manufactured by welding or splicing processes.

Commonly used welding methods include MIG welding or TIG welding.

Applications

Wellste Aluminum I beam provides a firm structural base for the framework. Owing to these useful properties, 6061 aluminum I beam is often used in trailers, trucks, automobiles, railcars, railings, and buses. It has strong strength, excellent hardness, and corrosion resistance.

Metro Station

Silo Tank

Hotel &Residences

Dam

You May also Interest

Contact us to get a free quote and more expertise about custom aluminum extrusion.

Aluminum I Beam with easy

Tell us what you need

Get Solution &Quote

Mass Production