- Certified no delivery delay

- Customizable aluminum products

- Cost-effective and low surface finishing cost

- Guaranteed zero concerns on designs and production

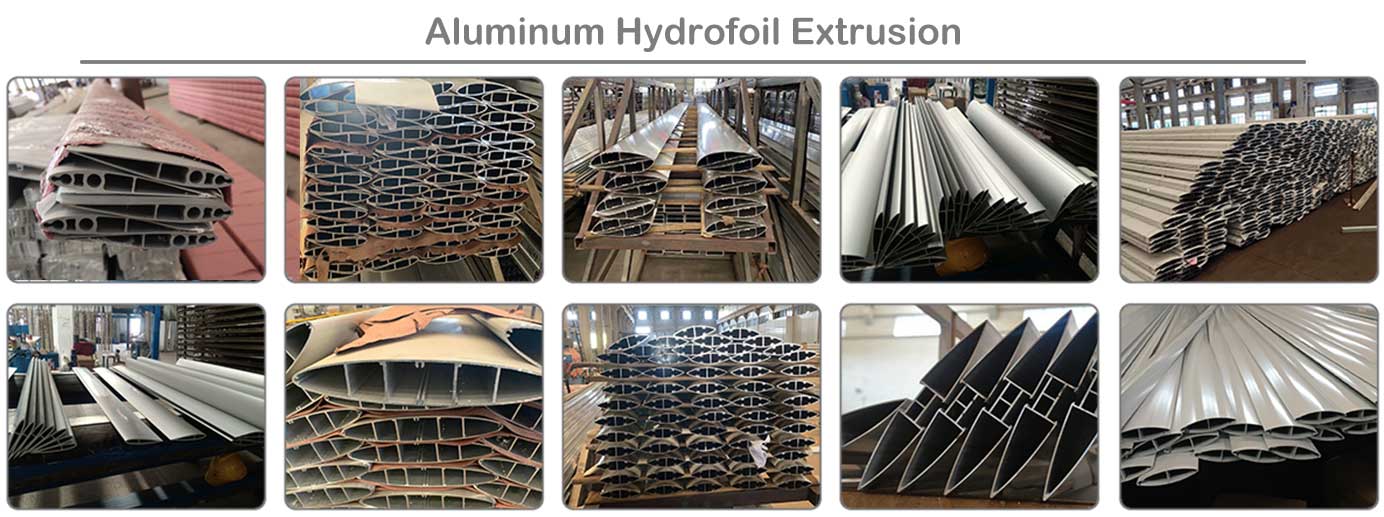

Aluminum Hydrofoil Extrusion

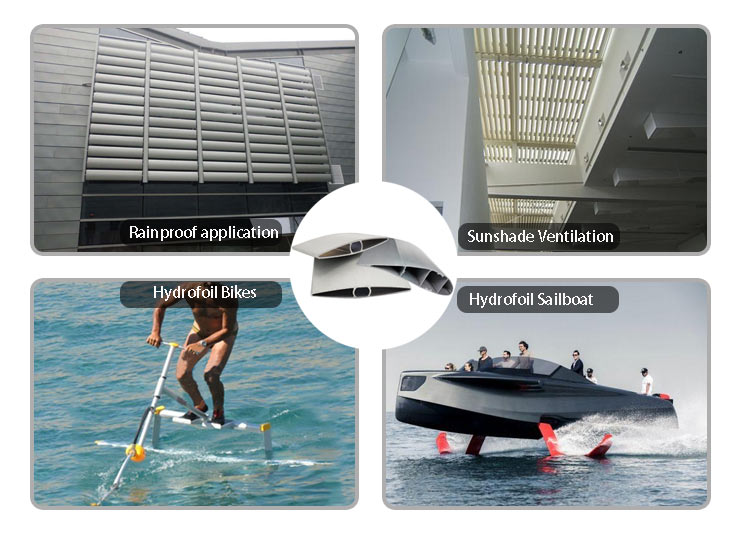

Aluminum Hydrofoil Extrusion is becoming a popular technique to make durable hydrofoil boats. Aluminum Hydrofoil Extrusion is also called extruded aluminum hydrofoils.

Known for its premium durability and corrosion resistance, Wellste aluminum hydrofoil extrusion is your best choice!

Wellste: The Top Aluminum Hydrofoil Extrusion Manufacturer

Wellste aluminum hydrofoil extrusion utilizes a comprehensive variety of aluminum series. Included are the 6xxx, 7xxx, and 2xxx series that are known for their high strength!

Wellste aluminum hydrofoil extrusions are enforced with surface finishes that enhance weather and corrosion resistance!

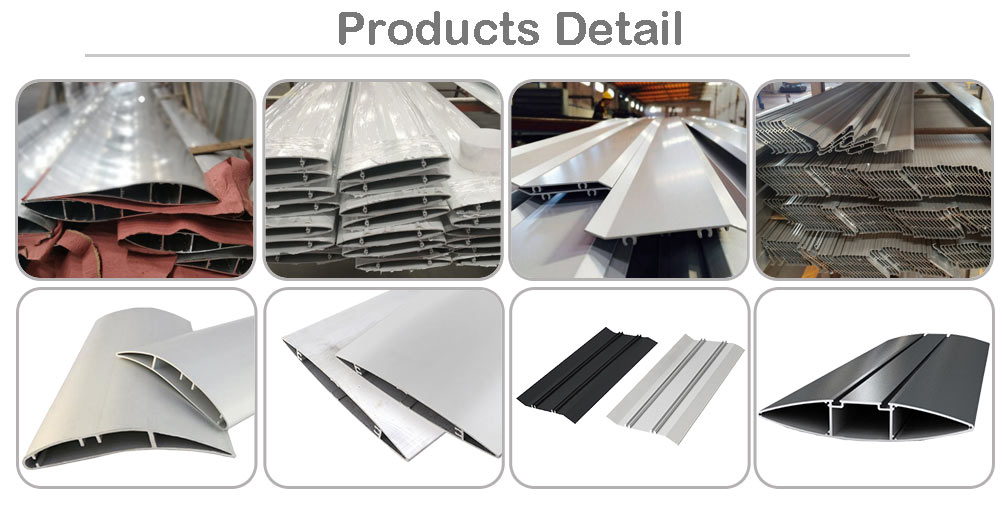

Wellste aluminum hydrofoil extrusion is available in finishes like anodization, powder coating, electrophoresis coating, and PVDF coating.

| Item Type | Aluminum Hydrofoil Extrusion |

| Material | 1000series ~ 7000series aluminium |

| Temper | T3-T8 |

| Application | Architectural, Industry, Window and Door Profiles, and so on. |

| Length | Long bar, or customized. |

| Surface treatment | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| Deep processing | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| Standard | GB, ASTM , AISI , DIN , BS, JIS |

| Certification | ISO9001 |

| Delivery Time | 15-20 days after sample confirmed & down payment, or negotiated |

| OEM/ODM | Acceptable |

| Service | 1. Free sample, Free design; 2. OEM/ODM available; 3. Custom-made request; 4. New design solution suggestion |

Wellste aluminum hydrofoil extrusions anodized passive oxide layer provides better wear resistance from long-term water abrasion.

Wellste’s modern anodization lines imported from Germany guarantee to serve aluminum hydrofoil extrusions of the highest quality crowned with strength.

Wellste aluminum hydrofoil extrusions are built to last even with long exposure to water and sunlight!

Wellste aluminum hydrofoil extrusions are used for rudders, propeller blades, daggers, centerboards, keels, etc.

The aluminum hydrofoil extrusions are employed with different highly durable alloy types that enhance the tensile strength from 70 MPa to about 700 MPa!

- Capabilities

- Workshop

- Package

-Standard Packing Option-

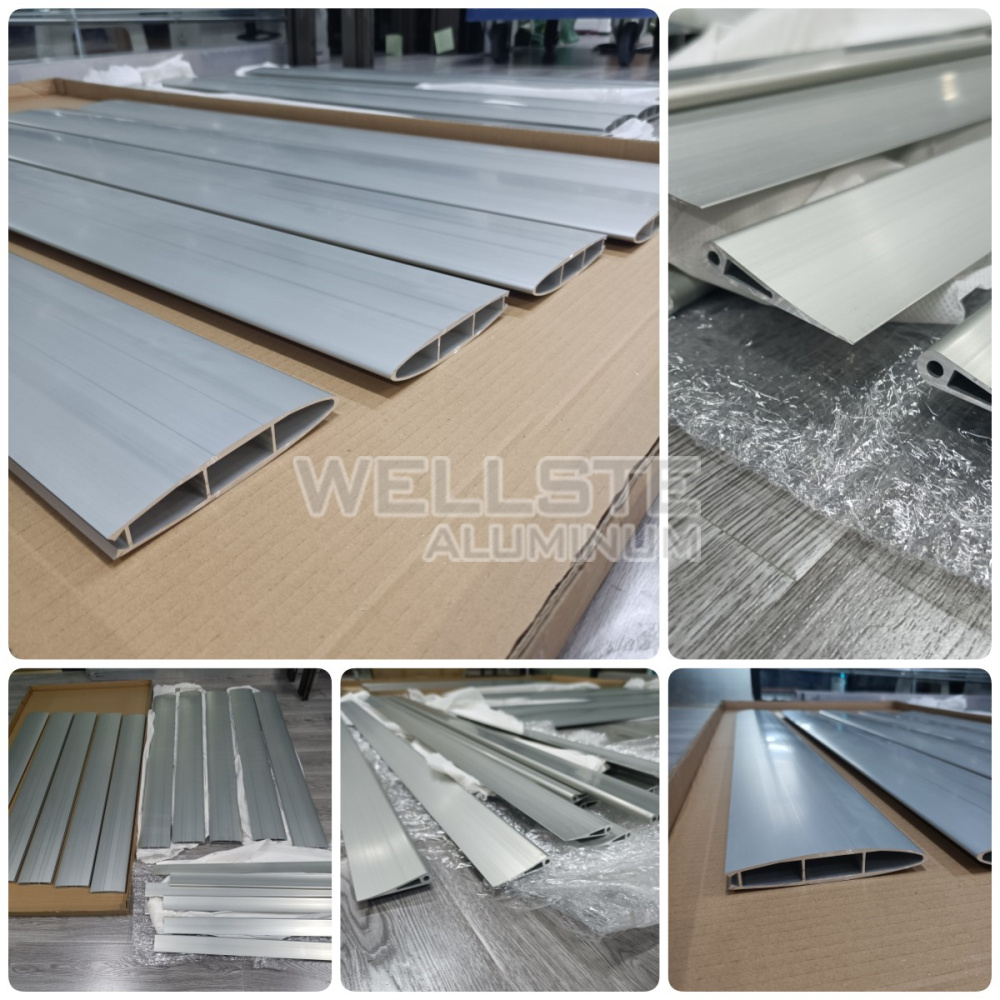

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

500kg, or $2000

Yes, Wellste is able to provide Aluminum Hydrofoil Extrusion for you to check the quality, Normally sample is for free for saving your cost, But it will require tooling costs if custom tube size.

It is only taking 7-10 days to complete your sample if the sample size is in stock.

For Aluminum Hydrofoil Extrusion, It takes a little bit long time to make extrusion tooling, commonly it requires 30-35 days to finish.

30% TT in advance, the balance payment is paid before shipment.

For Aluminum Hydrofoil Extrusion, its surface usually is anodizing or powder coating, you can choose Black, Silver, Red, Blue, Golden, Rose Red, Or can be discussed.

Related Products

Wellste: Your Professional Aluminum Hydrofoil Extrusion Manufacturer and Supplier

Wellste aluminum hydrofoil extrusions are specially designed to withstand the strong forces of waves!

Wellste’s team of experts design the Wellste aluminum hydrofoil extrusions with both quality and efficiency.

Wellste also can do other profiles, like Aluminum Airfoil Extrusion, Extruded Aluminium Louvre Blades, aluminium louver profile, roller shutter profiles, Aluminum Handrail Extrusions, Aluminum Handrail and Fence Extrusions, etc.

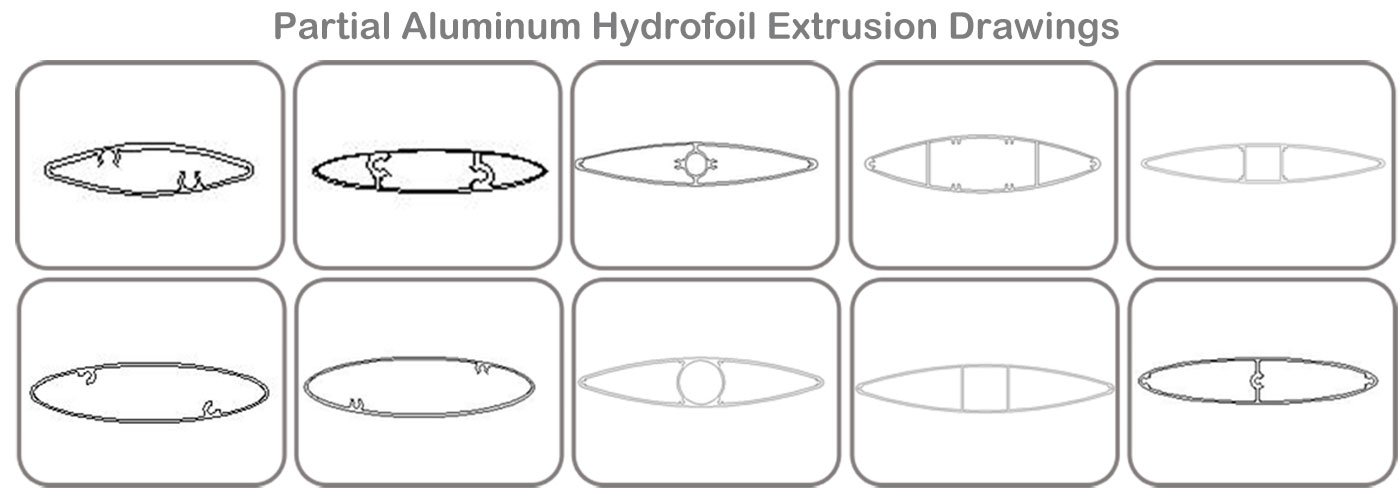

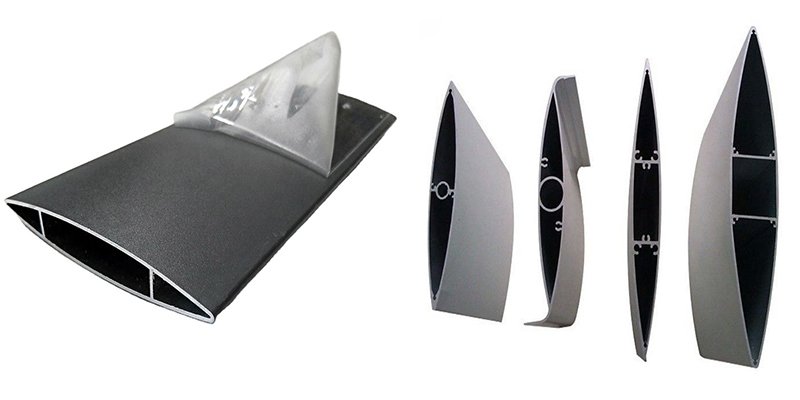

One of the most vital segments of the hydrofoils is the nose part. Thus, the Wellste aluminum hydrofoils extrusion process makes sure that it is made with maximum precision. High-precision and exceptional accuracy are achieved through Wellste’s 35 sets of advanced extrusion lines!

Another strong point of Wellste aluminum hydrofoil extrusion is its brilliant design! The aluminum hydrofoil extrusion features a big strength-to-weight ratio.

Wellste aluminum hydrofoil extrusion is very lightweight and is useful to provide greater hydrodynamic lift force. The aluminum hydrofoil extrusion features a big strength-to-weight ratio.

Also, aluminum alloy’s high ductility and malleability increase precision and help save production time and cost!

Wellste’s heavy-duty and cost-efficient aluminum hydrofoil extrusions are available in different profile variations!

With the help of our expert engineers, you can custom design your aluminum hydrofoil extrusions. You have the freedom to personalize your order on our comprehensive list of available size, shape, thickness, and surface finish.

The thickness of our centerboards is up to 35 millimeters. On the other hand, aluminum hydrofoil extrusion standard rudders are about 20mm to 25mm thick.

However, Wellste aluminum hydrofoil extrusion is available from 13mm to 35mm the standard thickness required. Great thickness infused with hard surface treatments makes Wellste aluminum hydrofoil extrusion your top choice when it comes to design quality, performance, and durability!

Wellste has ISO 9001-2008 and ISO 14001-2004 authorization, modern on-the-spot quality testing labs, and 48+ inspection team quality control! Our company provides one of the best quality assurance in China!

We take good care of our customers! For more than 20 years of focus on quality, Wellste guarantees you to have zero concerns through design, production, and delivery!

We assure no unnecessary delay and fast delivery of our products within or less than 25 days!

Wellste’s group of experts will be happy to design and manufacture your quality hydrofoil extrusions at competitive prices! Our group of responsive customer service assures response to your messages just within 8 hours! Request a quote now for hassle-free ordering!