- Durability

- Beauty Finish

- Corrosion resistance

-

Compact design and Aesthetic

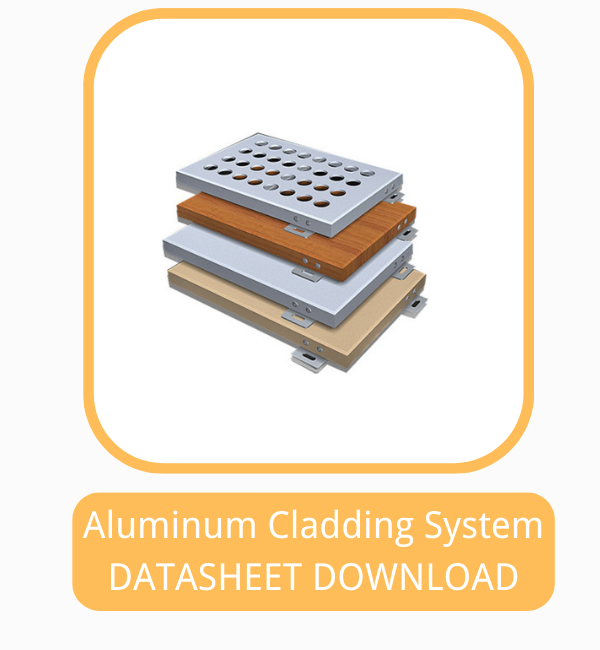

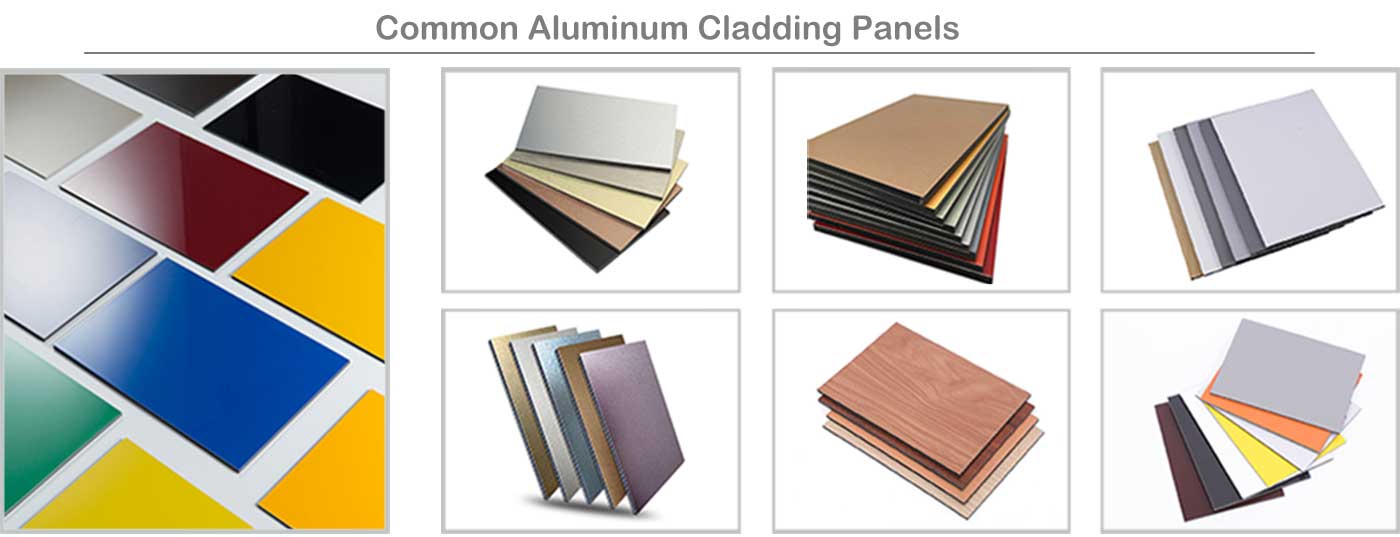

Aluminum Cladding System

Wellste is specializied in aluminum cladding system. We have more than 20 years of production experience.

Whether it is in terms of aluminium cladding panels price, quality, surface treatment, or, installation, Wellste will give you a better solution.

Wellste: The Top Aluminum Cladding System Manufacturer

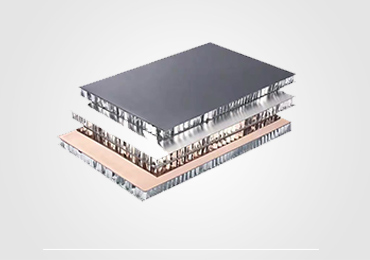

Hard aluminum and super hard aluminum have high strength, but they are not resistant to corrosion, In order to improve their corrosion resistance,

1% zinc high-purity aluminum or a zinc-aluminum alloy layer is often coating on hard aluminum acp sheet cladding surface. This is the aluminum cladding system.

The ACP cladding manufacturing process involves hot rolling an aluminum sheet onto a milled ingot, This greatly improves the corrosion resistance.

In addition to adding fireproof and waterproof materials, the aluminum composite cladding also forms a dense protective film, this provides an extra protection layer and ensures the construction cladding longevity and durability.

Based on different uses, ACP cladding systems divided into two types: process aluminum cladding and anti-corrosion aluminum cladding.

Process aluminum cladding is to improve the aluminum alloys processing performance (such as hot-rolled surface cracks).

Anti-corrosion aluminum cladding is a process to meet specific needs, usually used in construction or aviation.

Because the cladding aluminum composite panel is strong and durable, and has strong plasticity, it often used for aluminum wall panels and aluminium facade systems, such as ceilings, curtain walls, etc.

Considering that cladding for construction needs more performance requirements, Wellste will add fireproof and waterproof materials during the aluminum composite panel cladding production, to ensure the architectural safety performance.

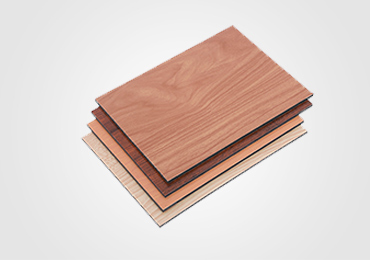

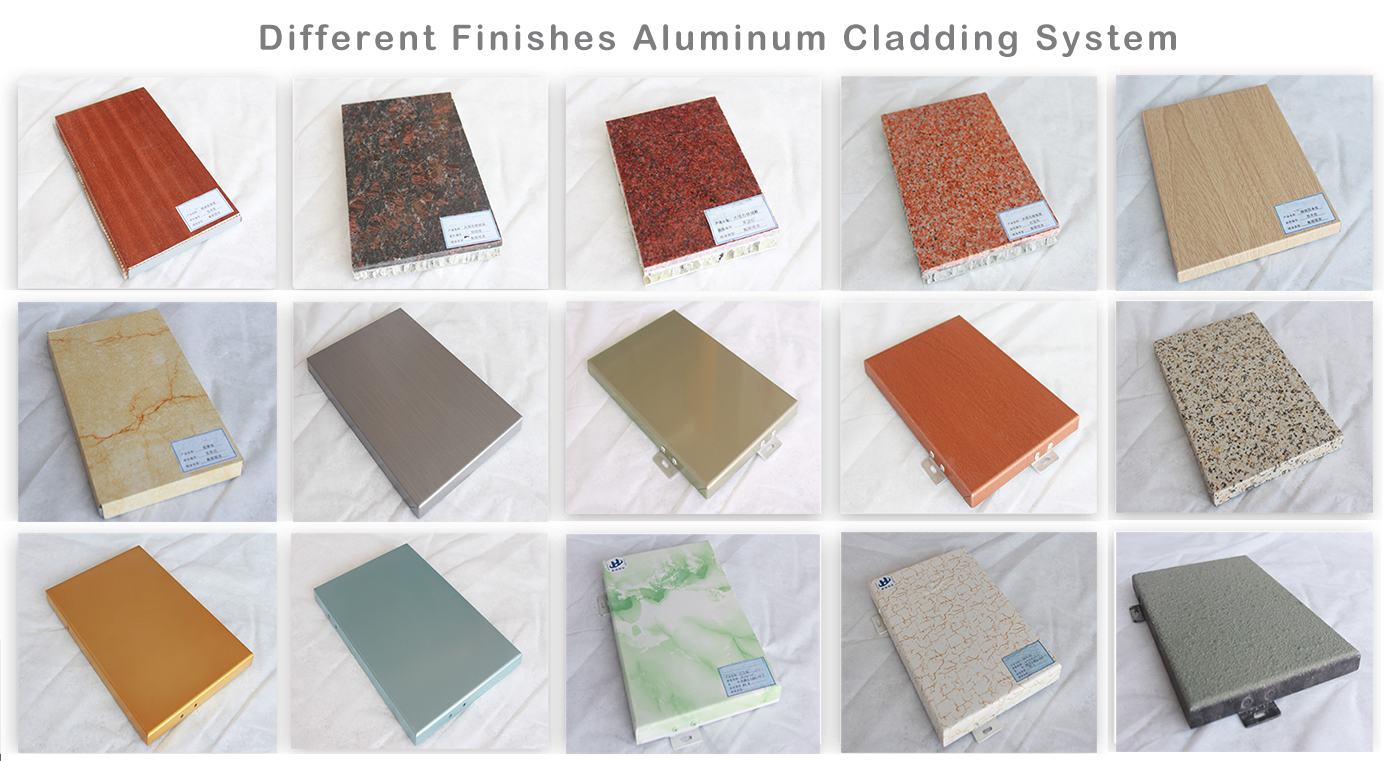

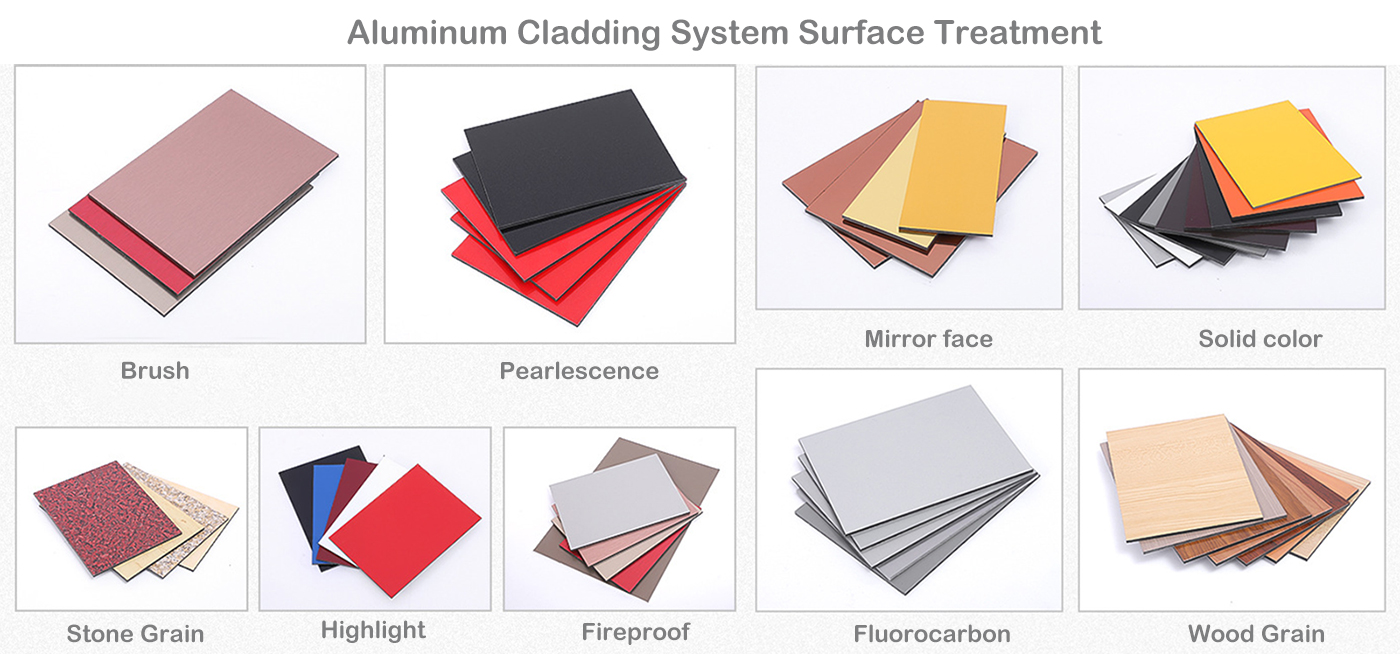

The acp cladding sheet has different surface treatment types, the more common ones are polishing, oxidation, PVDF, paint, etc.

The surface treatment process can protect composite panel cladding surface to achieve the effect of anti-corrosion and anti-oxidation.

Regarding aluminum cladding sheet finish, Wellste gives you more choices, such as embossing, solid color, high gloss, brushed, sandblasting, matte, mirror, etc. You can choose the suitable surface treatment according to your purpose.

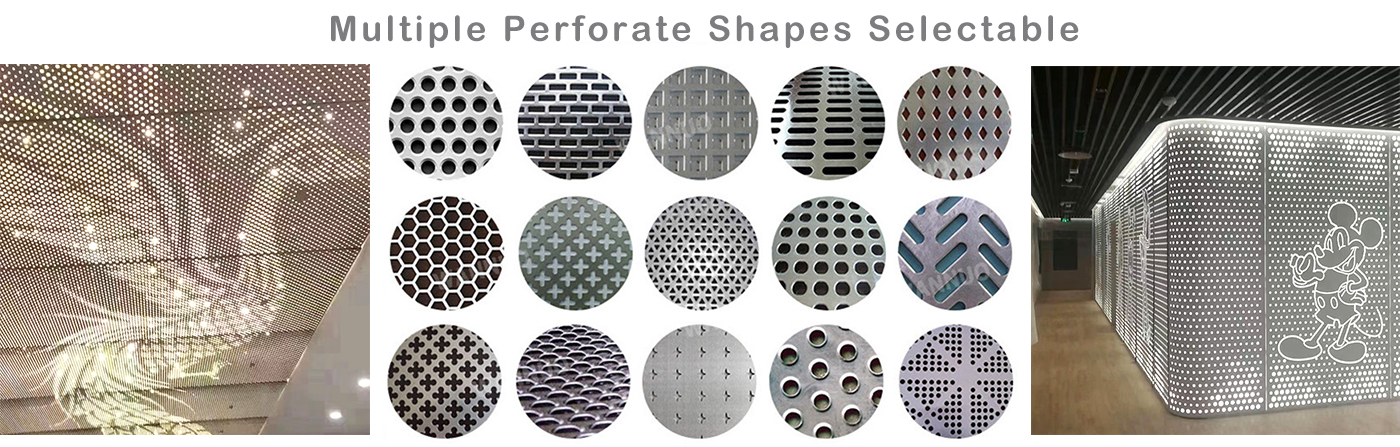

If you want to machining your aluminum composite cladding, we can also provide you with one-stop CNC services, such as perforated, folded, insulated, curved,cutting, laser marking, tapping, threading, groove, etc., Wellste could finish your products under one roof.

Wellste not only provide various aluminium sheet cladding colors, but also a choice of thickness, sizes, shapes, patterns, and so on.

Wellste provides customized service, you can customize any size and shape you want.

Wellste has its own strict aluminum cladding material testing system to conduct various performance tests on raw materials and finished products, such as metal strength, durability, corrosion resistance, etc, Ensure aluminium facade cladding can adapt to the worst weather conditions the surface beauty.

| Item Name | Aluminum Cladding System |

| Aluminum Grade | 6063, 6061, 6005, 6082 etc |

| Heat Treatment | T5 T6 T4 |

| Item Name | Aluminum Cladding System |

| Panel size | 1200*2400, 1400*3000, 1200*240, 1400*3000, 2000*6000mm or customized. |

| Total thickness | 10~100mm |

| Application | Home furniture, Building material,Industrial products, etc |

| Production Time | 15-20 days after payment arrived |

| Length | Long bar or cut to specific length |

| Surface treatment | Embossed, mirror, embossed, brushed, electroplated, anodized, matt, high-gloss. |

| Thickness | 0.04/0.06/0.08/0.1/0.12/0.15/0.18/0.2/0.25/0.3/0.35/0.4/0.45/0.5mm |

Regarding aluminium composite panel cladding later maintenance and cleaning, we give you some suggestions:

For aesthetic reasons, aluminium cladding profiles need regular simple cleaning, you can do by simply scrubbing with water or cleaning tools.

A fresh paint coat every year can help your aluminum exterior&interior wall panels keep its color looking good.

If you find your exterior aluminum panels facade or acp interior wall damaged, replace it immediately.

Get more aluminum cladding system information, send us inquiry now!

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Yes, Wellste is able to provide Aluminum Cladding System for you to check the quality.

Order amount should be more than USD 2000 with existing stock,

Customize Aluminum Cladding System should be no less than 500kg for each type.

It is only taking 3-5 days to complete your sample if the sample size is in stock.

For bulk orders, the lead time according to the factory production plan is usually 7-25 days.

30% T/T in advance, and the balance payment is paid before shipment.

Monochrome/Wood Grain/Stone Grain/High Gloss/Pearl/Brushed/Mirror/Fluorocarbon

Wellste is a manufacturer with over 20 years of experience in aluminum products.