- Anodized surface enhance corrosion resistance

- 6063, 6061 aluminum alloy no. with T5, T6 temper

- Comply with DIN-EN 755 European Aluminum Standard

- Long bar 3-6M or cut to specific short length as you require

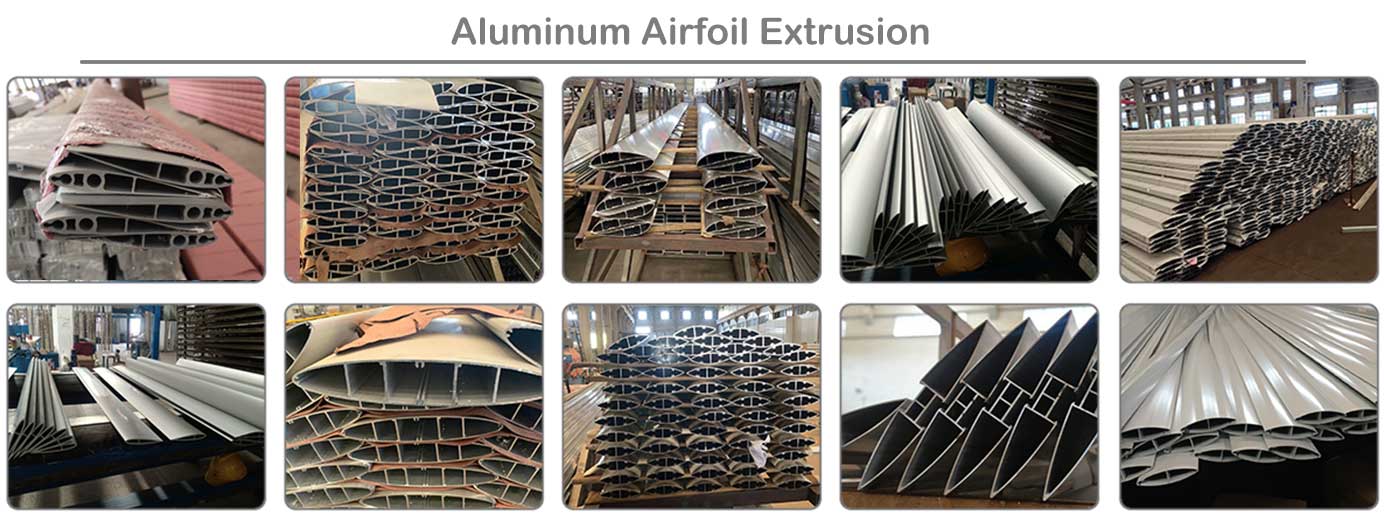

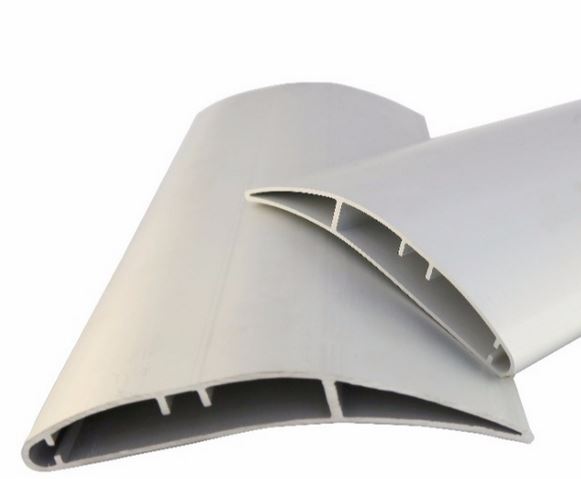

Aluminum Airfoil Extrusion

Wellste has broad range of Aluminum airfoil extrusion for your application needs.

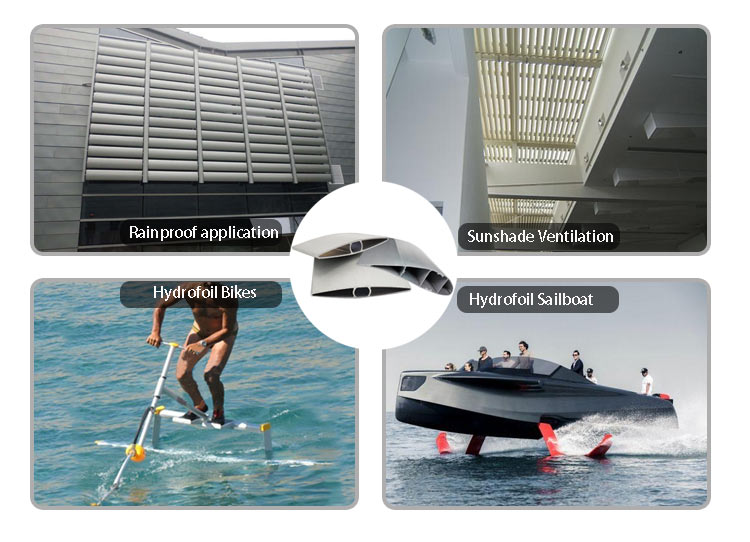

Our aluminium airfoil extrusion can be installed by Vertical, Horizontal, Roof Pattern, with fixed, manual, or motorized system including stationary.

Wellste: The Aluminum Airfoil Extrusion Supplier

Wellste aluminum airfoil extrusion is made up of aluminum alloy and aluminum 6063-t5, t6, For some marine or sea sports applications, it is also made up of aluminum 6061 T6.

| Item Type | Aluminum Airfoil Extrusion |

| Material | 1000series ~ 7000series aluminium |

| Temper | T3-T8 |

| Application | Architectural, Industry, Window and Door Profiles and so on. |

| Length | Long bar, or customized. |

| Surface treatment | Anodizing, Mill finish, Electroplating, Polishing, Sand blasted, Powder coating, Silver plating, Brushed, Painted, PVDF etc. |

| Deep processing | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| Standard | GB, ASTM , AISI , DIN , BS, JIS |

| Certification | ISO9001 |

| Delivery Time | 15-20 days after sample confirmed & down payment, or negotiated |

| OEM/ODM | Acceptable |

| Service | 1. Free sample, Free design; 2. OEM/ODM available; 3. Custom-made request; 4. New design solution suggestion |

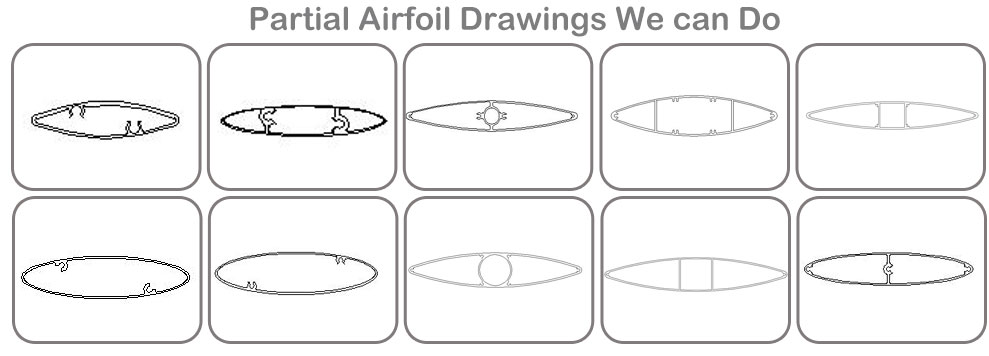

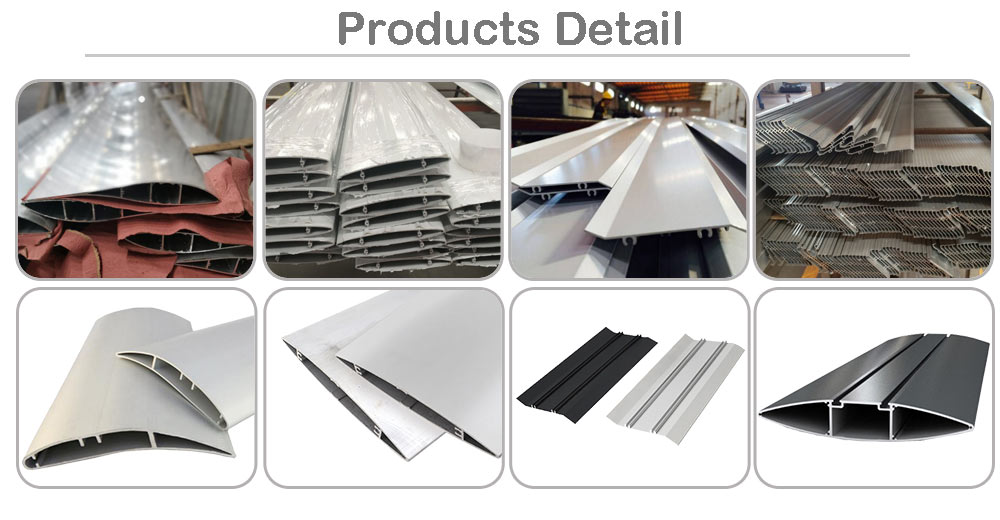

Wellste offers aluminium aerofoil extrusions with a wide variety of shapes. It can be tube, rectangular, olive or ellipse, flat, square, round, and many others.

You can choose among our aluminium aerofoil extrusions in different sizes or we can customize your desired shape according to your request.

Our professionals guarantee high precision to verify the authenticity of the aluminium aerofoil extrusions we manufacture for you to fit your needs.

Moreover, Wellste manufactures aluminum aerofoil extrusions in different colors.

At Wellste, the aluminium airfoil extrusion is usually available in wood grain color and RAL colors.

But we have a lot of aluminum aerofoil extrusions for you to choose or you can request us your ideal color of your aluminium aerofoil Extrusions.

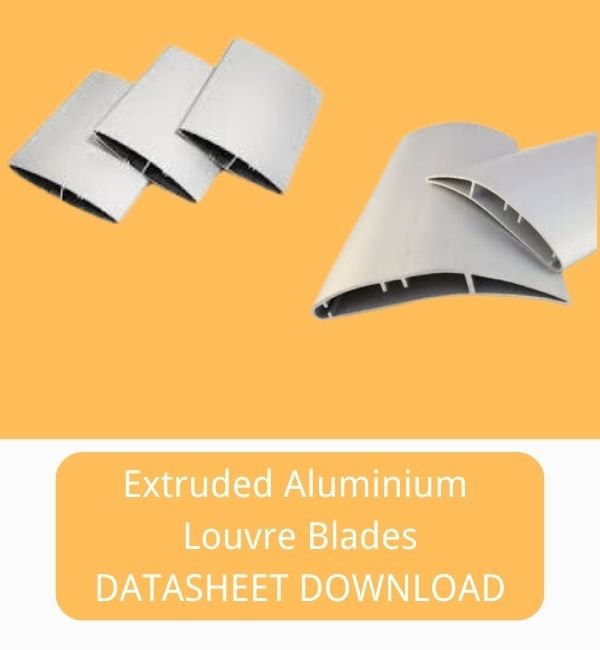

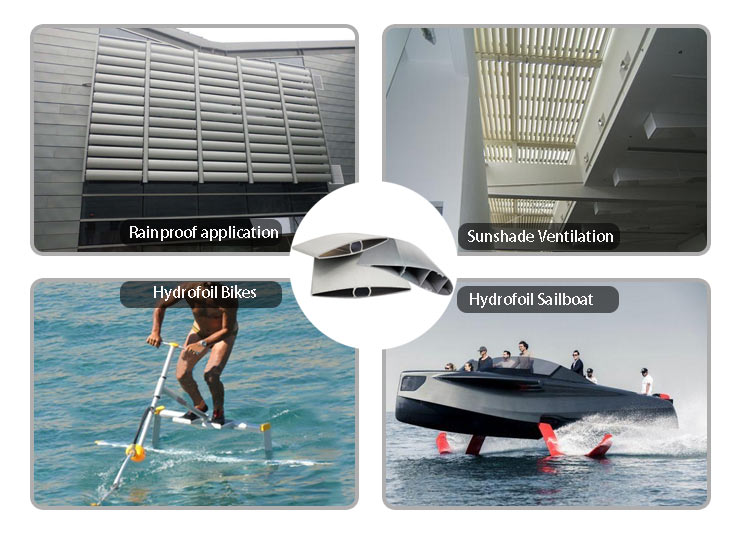

In addition, our aluminium airfoil axtrusion can be used for windows and doors, aluminum louver blade, architectural ventilation louvre, ceiling, solar panel, decoration, ladder profile, hydrofoil, etc.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

500kg, or $2000

Yes, Wellste is able to provideAluminum Airfoil Extrusion for you to check the quality, Normally sample is for free for saving your cost, But it will require tooling costs if custom tube size.

It is only taking 7-10 days to complete your sample if the sample size is in stock.

For Aluminum Airfoil Extrusion, It takes a little bit long time to make extrusion tooling, commonly it requires 30-35 days to finish.

30% TT in advance, the balance payment is paid before shipment.

For Aluminum Airfoil Extrusion, its surface usually is anodizing or powder coating, you can choose Black, Silver, Red, Blue, Golden, Rose Red, Or can be discussed.

Related Products

Wellste: Your Leading Aluminum Airfoil Extrusion Manufacturer

Wellste also can do other profiles, like aluminum hydrofoil extrusion, Extruded Aluminium Louvre Blades, aluminium louver profile, roller shutter profiles, Aluminum Handrail Extrusions, Aluminum Handrail and Fence Extrusions, ect.

In fact, we deal aluminium airfoil extrusion guaranteed with 10-40 years life span for doors.

At Wellste, you can order a different part number of aluminium airfoil extrusion with a standard sizes, colors, and shapes.

Wellste aluminium airfoil extrusion is very useful for government building, commercial building, exhibition hall, airport and hotel.

Furthermore, Wellste aluminum aerofoil extrusions is suitable for various façade, construction cladding, plane and bevel indoor.

Also, it is widely used for modern commercial building’s outdoor sun shading, glass roof for awning, curtain wall with large-scale glass, windows with a structure of grand building.

The choice of color slats is as architect, designer or requirements of the owner. That’s why, it harmonized the decoration of the building perfectly.

We offer you our easy to install Aluminum Airfoil Extrusion. Wellste manufactures aluminum airfoil extrusion with many advantages.

We provide aluminium aerofoil extrusions for strong sunlight protection, heat insulation, and low maintenance costs.

At Wellste, we deal aluminium aerofoil extrusions with long life span and can upgrade your building.

Wellste manufacture aluminium airfoil extrusion is available in basic surface treatment, the anodized surface. It is designed to have a good protection.

Wellste aluminium airfoil extrusion is also available in the electrophoresis surface which gives more durable and beautiful to your application. Aluminium airfoil extrusion with powder coating surface gives comfortable and colorful surface treatment.

As a professional and certified aluminum airfoil extrusion manufacturer and supplier, we can guarantee you our reliable, durable and excellent aluminium aerofoil extrusions in order to meet the requirements of every application.

Contact us today! You can get our technical staff is 24/7 fast response.

Aluminum Airfoil Extrusion: The Ultimate FAQ Guide

If you have any question about aluminum airfoil extrusion, you will find the answer right here.

This guide covers everything about aluminum airfoil extrusion – from features, extrusion process, tooling, surface treatments, cost and classification, just to mention a few.

So, if you want to be an expert in aluminum airfoil extrusion, read this guide.

- What Is Aluminum Airfoil Extrusion?

- Why Is Aluminium Extrusion Important?

- What are the Advantages of Aluminium Material for Airfoil Extrusion?

- What are the Aluminium Extrusion Process Advantages?

- What is the Typical Application of Aluminium Airfoil Extrusion?

- What are the Various Sizes of Aluminium Airfoil Extrusion Available?

- Are there Length Restrictions for Aluminium Airfoil Extrusion?

- Which Shapes and Patterns does Aluminium Airfoil Extrusion Come In?

- What are the Factors to Consider for Aluminium Airfoil Extrusion Design?

- How is Aluminium Airfoil Extrusion Made?

- Which Grades of Aluminium Alloy are Used to Make Aluminium Airfoil Extrusion?

- What is Aluminium Airfoil Extrusion Die?

- How Long does Aluminium Airfoil Extrusion Die Last?

- How do you Install Aluminium Airfoil Extrusion for Different Applications?

- What is BS EN 12020 for Aluminium Airfoil Extrusion?

- What are Some Inspection Methods used in Aluminium Airfoil Extrusion?

- What is the Cost of Aluminium Airfoil Extrusion?

- What is the Typical Tooling Cost for Aluminium Airfoil Extrusion?

- What is the Minimum Order Quantity of Aluminium Airfoil Extrusion?

- How is Aluminium Airfoil Extrusion Packaged?

- Which are the Available Color Options for Aluminium Airfoil Extrusion?

- What Determines the Durability of Aluminium Airfoil Extrusion?

- What are the Surface Treatment Options for Aluminium Airfoil Extrusion?

- Is there a Recommended Powder Coating Thickness For Aluminium Airfoil Extrusion?

- Can I Order Samples of Aluminium Airfoil Extrusion?

- How Strong is Aluminium Airfoil Extrusion?

- What is the General Tolerance for Aluminium Airfoil Extrusion?

- What are the Different Joining Methods for Aluminium Airfoil Extrusions?

- Is Aluminium Airfoil Extrusion Recyclable?

- What is Temper for Aluminium Airfoil?

- Which are the Typical Tempers for Aluminium Airfoil Extrusion?

- Are there Any Limitations to Using Aluminium Airfoil Extrusion?

- What is the Difference Between Aluminum Extrusion and Roll Forming?

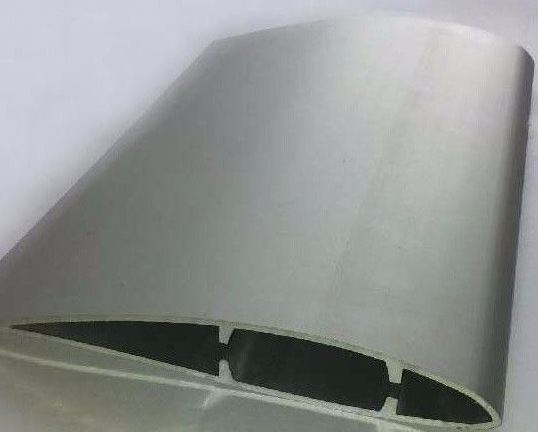

What Is Aluminum Airfoil Extrusion?

Aluminum Airfoil Extrusion refers to aluminum metal extruded into various shapes and sizes.

The different extruded aluminum airfoil designs allow for use in a variety of areas, including in building and sea sport applications.

They are popular because of their toughness and durability, in addition to quality of aluminum airfoil extrusion.

Aluminum Airfoil Extrusion

Why Is Aluminium Extrusion Important?

One of the main importance of aluminum extrusion is that the process allows the production of very complex cross-sections.

Also, aluminum extrusion is essential as it helps the material adapt the cross-sectional profile and maintain its profile up-to-the final extrudate.

What are the Advantages of Aluminium Material for Airfoil Extrusion?

Here are some of the benefits of using aluminum for airfoil extrusion:

1) Recyclable

The advantage of using aluminum is the ability to use it many times without worrying about it degrading.

This is a feature that enhances the efficiency of the material and makes it superior over other materials.

2) High Strength

Aluminum allows you to make the airfoil extrusions as strong as you want them to be. The material enables you to concentrate on the point you would wish the strength to be.

3) High Strength-to-Weight Ratio

Aluminium is relatively light, which is a feature that makes it easier to handle.

Also, this lightweight property of aluminum makes it inexpensive to ship.

Fitness, sports, and transportation sector use aluminum airfoil extrusion due to this particular feature.

4) Resilient

This aluminum airfoil extrusion advantage allows you not worry about the amount of weight it will bear.

This is because aluminum is a light yet very robust material.

5) Corrosion Resistant

One element that makes aluminum an ideal material to use in airfoil extrusion is that it does not rust.

This is because anytime aluminum reacts with oxygen, it forms a thin oxide layer that is resistant to corrosion resistant and durable.

Moreover, the layer forms another one immediately in case you scratch it.

This is in addition to aluminum being an alloy capable of resisting corrosion when exposed to salty water or any other chemical.

6) Thermally Conductive

Aluminium is among the few materials that can conduct heat during heating or cooling applications.

7) Reflective

Aluminum is 80 percent reflective. Not only does it reflect light, but also it reflects infrared radiations and radio waves.

You can apply this characteristic of aluminum airfoil extrusion to produce an aesthetic feature.

8) Non-magnetic

This feature makes aluminum a preferred material in high-voltage hardware such as MRI or machines making use of magnetic fields.

Non-combustible and non-sparking

This feature makes it the right choice for areas that are susceptible to explosion.

Also, you do not have to worry about exposing aluminum to heat because it does not produce any hazardous emissions.

Cryogenic Strength

Cryogenic is the behavior materials exhibit when present in cold temperatures.

One thing that makes extruded aluminum airfoil ideal is that it gains strength when subjected to cold temperatures.

Offer Wide Range of Finishes

Aluminium does not limit you on the number of finishes you can achieve.

Easy join of Aluminum Profile

You can use brazing, mechanical fastening, soldering, adhesive in attaching aluminum airfoil extrusion to other aluminum products.

What are the Aluminium Extrusion Process Advantages?

Here are some of the advantages of the aluminum extrusion process:

Cost-effective

Unlike other molding processes, extrusion is a relatively low-cost procedure. Furthermore, you can easily recycle most of the waste material obtained during the process.

This additionally lowers the cost of disposal and raw material.

Broad Variety of Finishes

Using this method, you are confident that you will not get tied down to one particular finish.

This advantage comes in handy, particularly when you wish to extrude several materials and still maintain their finish variation.

Attractive

This is mainly why many people prefer extruded aluminum.

Extrusion makes the finishing of the aluminum airfoil appear quite appealing.

Flexibility of Operation

The flexibility feature is of benefit when you wish to manufacture different products and still maintain a cross-section pattern.

Short Lead Times

This is a huge bonus when you wish to extrude a number of materials.

This is because you are confident that the extrusion process will not take you too long.

Wide Range of Products

Another benefit of aluminum extrusion process is that it does not limit the type of products you can produce.

Not only can it offer pipes, wire rods, and rods, it can also make solid and cross-sectional shapes.

Improved Quality

Extrusion tends to help improve the structure of aluminum. The extrusion also helps improve the mechanical properties of aluminum.

Also, compared to other methods like roll forming forging, extruded aluminum airfoil tends to have great dimensional accuracy and better surface quality.

Simple Process

Compared to other processing methods; extrusion tends to have few procedures.

It gets better as the process does not require a lot of equipment.

What is the Typical Application of Aluminium Airfoil Extrusion?

Here are some of the areas you can use aluminum airfoil extrusion:

Aluminum Extrusion for Construction

This application ranges from building bleachers to railings.

Aluminum airfoil extrusion is ideal for construction because of its lightweight feature.

You can use the extruded aluminum while constructing canopies.

This is because aluminum can hold a lot of weight due to its strength and still maintain its tolerance.

Display Equipment

In most cases, most stands used in trade shows are often from an extruded aluminum airfoil.

This is because interlocking the small pieces is relatively easy and quick.

Moreover, it is pretty easy to move due to its light weight.

Some of the display structures include display cabinets and picture frames.

Electrical Systems

Aluminum airfoil extrusion is a great conductor. This is why it finds application in electrical equipment and busbars.

Extruded aluminum airfoil also makes a suitable heat exchanger or radiator.

Industries

Most factories make use of aluminum airfoil extrusion for inspection tables, carts, and workbenches.

The industries prefer using this product as it is easy to drill and cut.

Transportation

In transportation, weight matters. This is why the industry prefers using extruded aluminum airfoil due to its light weight and sturdy features.

Extruded Aluminum Airfoil Applications

What are the Various Sizes of Aluminium Airfoil Extrusion Available?

There are different sizes of aluminium airfoil extrusion and they include; 20,25,30,40,45,50,60 mm. Note that the sizes vary on the type of alloy.

Are there Length Restrictions for Aluminium Airfoil Extrusion?

No, there is no a length restriction for aluminum airfoil extrusion, which ranges between 1.0 to 6.0 meters.

In order to ensure that you have the right measurement, you should leave some allowance for scrap.

The allowance should be at the beginning and at the end.

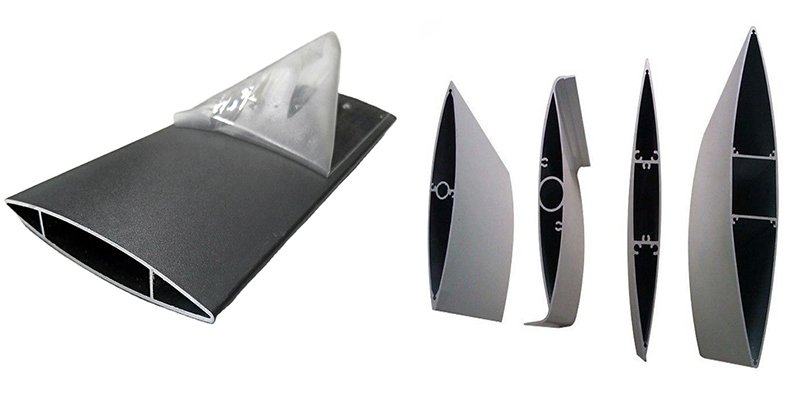

Which Shapes and Patterns does Aluminium Airfoil Extrusion Come In?

Here are some of the shapes and patterns aluminum airfoil extrusion come in:

Solid Shapes

You can use these shapes in products like rods and solid bars with different cross-sections (rectangles, squares, and circles.)

Semi-solid Shapes

These shapes involve angles, channels, or any other partially open forms.

Hollow Shapes

Products with hollow shapes include tubes. This shape completely encloses the opening.

What are the Factors to Consider for Aluminium Airfoil Extrusion Design?

You can produce different shapes and designs of extruded aluminum airfoil.

Let’s look at some of the considerations when designing aluminum airfoil extrusion:

Circle Size

It is imperative to ensure that you only work with a manufacturer who can offer the kind of circle size you need. This is because not every manufacturer offers a full range of options.

Weight per Foot

You ought to take into account the weight per foot before you start making any design. This is because the measurement greatly influences the operation of the press and the press size.

Shape Constraints

For you to achieve the best extrusion shape, it is ideal to consider all the shape limitation of the design.

Tongue Ratio

For you to have an optimum extrusion process, it is best that you avoid having a high tongue ratio.

Tolerance Finish

It is advisable to assess the capacity the material can endure while designing the surface finishing.

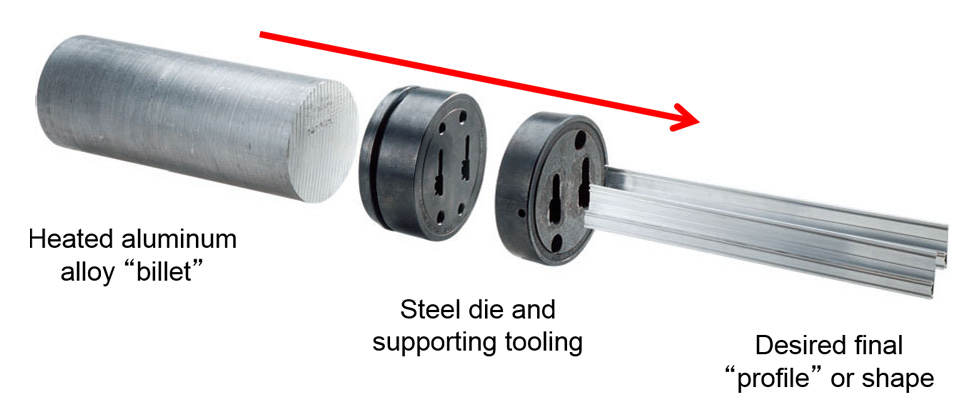

How is Aluminium Airfoil Extrusion Made?

Here are some of the steps involved in the making of aluminum airfoil extrusion:

Aluminum Airfoil Extrusion Process

- You develop the extrusion die and then move to the extrusion press. Here you forge a round-shaped die from H13 steel.

It is advisable to preheat the die between 400-500 degrees Celsius before you start extrusion.

Preheating the die helps maximize its lifespan and make sure that it offers an even metal flow.

After preheating, you can now load the die in the extrusion press.

- Preheating aluminum billet before doing extrusion. A billet is a solid, cylindrical block of aluminum alloy.

The billet is cut from a more extensive log of alloy material, which you preheat in an oven. Preheating the billet is important since it helps to make it malleable enough for it to work during the extrusion process.

- Transferring the billet to extrusion press: You then mechanically transfer the preheated billet to the extrusion press.

Before the transfer, you need to lubricate the billet. You should also lubricate the ram to prevent it from sticking to the bullet.

- The ram impels the billet material into the container. Here, the hydraulic ram puts pressure on the billet, pushing it in the extrusion press container.

During this process, the material expands for it to fit in the container.

- The extruded material emerges through the die. While the alloy materials fill the container, the system presses the extrusion die against it.

During this stage, the process forces the aluminum material to go through die’s opening due to continual pressure applied to it. Once it emerges from the die’s opening, you shape it in the form of a fully-formed profile.

- Extrusion moves along the runout table and as it cools. Once the extruded material emerges, the puller grips the extruded material.

The puller directs it along the runout table at a speed that is equivalent to its exit from the press. As the extruded aluminum airfoil moves along the runout table, water or fan above the table cool it uniformly.

- Shearing of the aluminum extrusions at the table length: The hot saw shears the aluminum airfoil extrusion only when it reaches its full table length.

This helps in separating the extruded aluminum airfoil from the extrusion process. Temperature plays a big role during this step.

- The extrusion is cooled at room temperature- The table-length extrusion is transferred from the runout table to a cooling table. Note that the table-length extrusion will remain there until they are at room temperature.

The table-length aluminum extrusions get stretched once they reach room temperature.

- The system moves the extruded aluminum airfoil to the stretcher. Not that there are some alternations in the profile during these processes.

There is need to stretch the extruded material so as to correct it. You mechanically grip the profiles on both sides and stretch then until every aspect is right.

- After stretching and hardening the table-length aluminum airfoil extrusion, you transfer them to the saw table. The table-length extrusion is cut to a specific measurement.

Subsequently, you heat the extrusion to improve the properties of aluminum airfoil extrusion.

After the heat treatment, the extrusion obtains different surface finish in order to prevent corrosion and to improve their appearance.

Which Grades of Aluminium Alloy are Used to Make Aluminium Airfoil Extrusion?

The common aluminum alloys used in the fabrication of extruded aluminum airfoil include:

- Aluminum alloy 6063: This is the preferred alloy because it offers a high-quality finish.

- Aluminum alloy 6061: This is a medium-strength alloy that has good non-corrosive abilities. It is suitable for machining as it is known as a structural alloy.

- Aluminum alloy 6005: It has a high minimum composition percentage with a treatable heat attribute.

- Aluminum alloy T5 and T6: T5 refers to aluminum that is air-cooled. On the other hand, aluminum alloy T6 is one cooled by water for each to reach higher hardness properties.

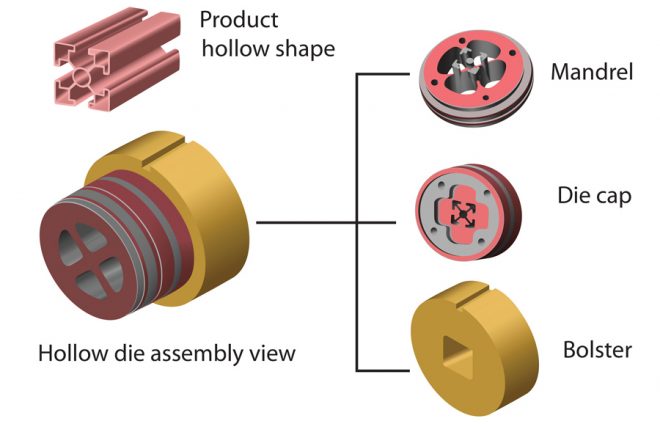

What is Aluminium Airfoil Extrusion Die?

An aluminum airfoil extrusion die is a thick circular steel disc with one or more openings essential in creating the preferred profile.

Malleable aluminum passes through the disk during the extrusion process.

Hollow Aluminum Airfoil Extrusion Die Set

How Long does Aluminium Airfoil Extrusion Die Last?

The uneven pressure that goes in the profile’s design is one element that reduces the longevity of the die.

Hence, to improve the durability of the die, it is imperative that you design a die that can easily control the heat.

Moreover, the die should not be affected by the uneven pressure.

How do you Install Aluminium Airfoil Extrusion for Different Applications?

There are different ways you can install the aluminum airfoil extrusion. You could choose to install it vertically, horizontally, or roof pattern.

Note that the installation method you choose is dependent on how you intend to use the aluminum airfoil extrusion.

What is BS EN 12020 for Aluminium Airfoil Extrusion?

This is a European standard that details out the tolerance on the dimension and the precise form profile.

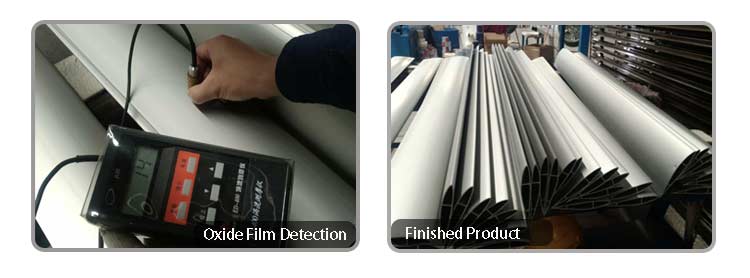

What are Some Inspection Methods used in Aluminium Airfoil Extrusion?

Here are some of the inspection methods used to extrude aluminum airfoil extrusion:

Aluminium Alloy Check

This inspection ensures that you are using the right type of aluminum. Some of the aluminum alloy approved internationally are 6063, 6061, and 6005.

Extrusion Die Inspection

Here, you check hardness elements, bearing squareness and length, dimensional measurement, and support for thin parts.

Consult an expert if you are not certain on factors to address for your extrusion die.

Additives Check

Some of the additives used in extruded products are colors, stabilizers, finishing materials, and flame retardants.

Before using additives, it is essential to ensure that you communicate with the suppliers before the extrusion process starts.

Visual Defects Check

Some of the factors inspected during visual defects check are uneven coatings, internal cracking, uneven wall thickness, black specks.

It is imperative to know these factors as it will act as a guide to your supplier and inspector.

Ask for sample from your supplier if you do not understand what to assess during visual defects check. The sample will guide you on what you need to check.

Dimensional Inspection

In this inspection method, you ought to check on the holes’ location and size, wall thickness, width, mitered, and length joints.

Corrosion Resistance

This test includes checking whether the extruded aluminum airfoil has excellent corrosion resistance.

Some of the test conducted during this inspection is humidity resistance and salt spray test.

Hardness Test

This test helps verify that the extruded aluminum airfoil meets the required hardness properties.

What is the Cost of Aluminium Airfoil Extrusion?

The cost of aluminum airfoil extrusion ranges between USD 900 to USD 1500.

Extruded aluminum airfoil

What is the Typical Tooling Cost for Aluminium Airfoil Extrusion?

Here is a detailed tooling cost for aluminum airfoil extrusion:

a) Process Typical Tooling cost in USD

- Steel extrusion: 300 and above

- Stampings for machining process:

- (Short run) minimum

- (Long run) is 5,000 and beyond

Remember, these cost vary depending on the design and features of the aluminum airfoil extrusion.

At Wellste, we offer cost competitive aluminum airfoil extrusion rates.

What is the Minimum Order Quantity of Aluminium Airfoil Extrusion?

The minimum order quantity of aluminum airfoil extrusion is 500 to 1000 pounds.

How is Aluminium Airfoil Extrusion Packaged?

Proper packaging helps protect aluminum airfoil extrusion from any damages during transportation.

There are a few things that determine the kind of packaging that you ought to use.

These include the market location and transportation time and distance. For instance, the ideal packaging for extruded aluminum airfoil meant for local market is craft paper, wood pallets, or wood crates.

Moreover, you can store the aluminum airfoil extrusion using craft paper, PE foam, plastic box, or carton tube.

The machine used in packaging aluminum airfoil extrusion include:

- Aluminum wrapping machines

- Aluminum film application machines, and

- Aluminum automatic bagging machines.

Which are the Available Color Options for Aluminium Airfoil Extrusion?

You can find extruded aluminum airfoil in the following colors:

- Black

- Silver

- Golden

- Red

- Blue

What Determines the Durability of Aluminium Airfoil Extrusion?

Aluminum air foil extrusion section

One element that makes aluminum airfoil extrusion very durable is that it cannot rust. The thin oxide layer that forms on its surface helps protect the aluminum material.

Also, it is very strong. Therefore, it does not matter the amount of weight you put on it as it has excellent tolerance.

What are the Surface Treatment Options for Aluminium Airfoil Extrusion?

The popular surface finish option for extruded aluminum airfoil consist of:

· Mechanical Finishes

This type of surface treatment is available in different textures. You can develop the textures using several mechanical methods like polishing, blasting, sanding, buffing.

· Chemical Finishes

Aluminum airfoil extrusion finish of this type involves etching. It provides a frosted surface appearance which offers a shiny surface.

· Anodizing

The technique allows the aluminum profiles to maintain their metallic luster while accepting vibrant color and durable feel.

· Powder Coatings

This kind of treatment provides a durable finish while not using any solvents.

· Electrophoresis

This surface treatment involves removing of grease, which helps to harden the aluminum. By using this kind of surface, treatment option helps in providing smooth features.

Is there a Recommended Powder Coating Thickness For Aluminium Airfoil Extrusion?

Yes, the recommended powder coating thickness for aluminum airfoil extrusion ranges between 70 to 130 microns.

Can I Order Samples of Aluminium Airfoil Extrusion?

Yes, you can place a sample order. When placing your order, make sure that you detail the right measurements to have better picture of the product you will receive.

How Strong is Aluminium Airfoil Extrusion?

Aluminum airfoil extrusion is a very sturdy product. The strength ability ranges between 190 to 310 MPa.

What is the General Tolerance for Aluminium Airfoil Extrusion?

There is standard tolerance for aluminum airfoil extrusion, and it is 0.012″.And the dimension tolerance is decided on the size.

What are the Different Joining Methods for Aluminium Airfoil Extrusions?

There are different joining methods you can use for aluminum airfoil extrusion; they include:

Nesting Joints

A nesting joint involves using of tongue-and-groove joints and lap joints. This kind of method does not need any self-locking action or may require little self-locking action.

Interlocking Joints

This is a modified nesting joint. The mating elements in interlocking joints are curved.

This simply means it is hard to disassemble or assemble it using a straight-line motion.

While using interlocking joints, you need to use a rotating motion while assembling, and counter-rotation motion while disassembling.

You do not have to worry about the joints disassembling as it has parts firmly assembled in both vertical and horizontal directions.

Snap-Fit Joints

This is a self-locking method, thus does not require any fasteners for it to hold together. You can apply it to join flexible regions.

The good thing is that you are certain that you cannot disassemble unintentionally by using this type of method.

Three-Piece Interlocking Joint

This joint entails using a hidden fastener interlocking the two principal extrusions. The design includes one side that has a smooth appearance.

The joining technique features no visible mounting hardware.

Combination Joints

A combination joint involves using different types of joints in the same extruded assembly. For instance, you can use rotating elements with snap-fit elements.

Slip-Fit Joint

You obtain this type of joint by sliding two extruded mating parts while factoring in the direction of their length.

There are three classes of this joint including rigid dovetail joints, freely-rotating joints, and close-fitting.

Hinge Joints

This kind of joints allows motion. You achieve it by using the ball and socket shapes that permit rotation without causing any separation.

Key-Locked Joints

This joint has two or more primary elements which get locked together. This type of interlock makes it easy to assemble and disassemble.

The joint makes it an ideal method when you wish to have a temporary installation.

Screw Slots

In this technique of joining Aluminum Airfoil extrusion, the slot has single horizontal identification.

Is Aluminium Airfoil Extrusion Recyclable?

One feature that makes aluminum the preferred material for making metal extrusion is its recyclable attribute.

This is because aluminum retains its properties regardless of its prevailing conditions.

China Aluminum Airfoil

What is Temper for Aluminium Airfoil?

Temper is a designation that appears as hyphenated suffix tagged to the alloy number.

Remember that you classify all alloys based on their heat-treatable or non-heat-treatable features.

Those classified as non-heat treatable often manifest their strength during cold work while you are extruding.

Some of the most suitable alloys are 6063, 6061 aluminum alloy no. with T5, T6 temper.

Whereas the heat-treatable alloys tend to gain their strength under controlled heat treatment.

Note that the heat-treatable heat alloy tends to have the strongest aluminum alloys.

Here are some of the tempers for aluminum airfoil extrusion:

- F extruded: The alloy does not have any special thermal control; it does not possess any strain-hardening properties. Also, it has no mechanical property limits.

- Annealed: This is a type of temper that you need to thermally treat to receive the lowest strength temper.

- T thermally treated: You need to thermally treat the extruded aluminum airfoil for it to get stable tempers other than F, O and H.

An example of how a designated alloy-temper reads is 6063-T5. This alloy indicates that it is in the 6xxx series that you need to thermally treat for stable tampers.

Which are the Typical Tempers for Aluminium Airfoil Extrusion?

- T5 that you cool from a raised temperature and it is not naturally aged.

- T6 Solution that is heat-treated and it is not naturally aged.

Are there Any Limitations to Using Aluminium Airfoil Extrusion?

There are a few limitations to using aluminum airfoil extrusion; they include:

- There is uneven tissue performance of products. This is due to the non-uniformity during the extrusion process.

The inconsistent tissue performance can be a lot, especially if there is no lubricant.

- The working conditions of extrusion die are hard, and it can quickly wear out. There are high temperatures and high friction during the extrusion process, and the die can easily wear out during this process.

- Low production efficiency. You cannot conduct continuous production while doing extrusion because of the relatively slow speed of extrusion.

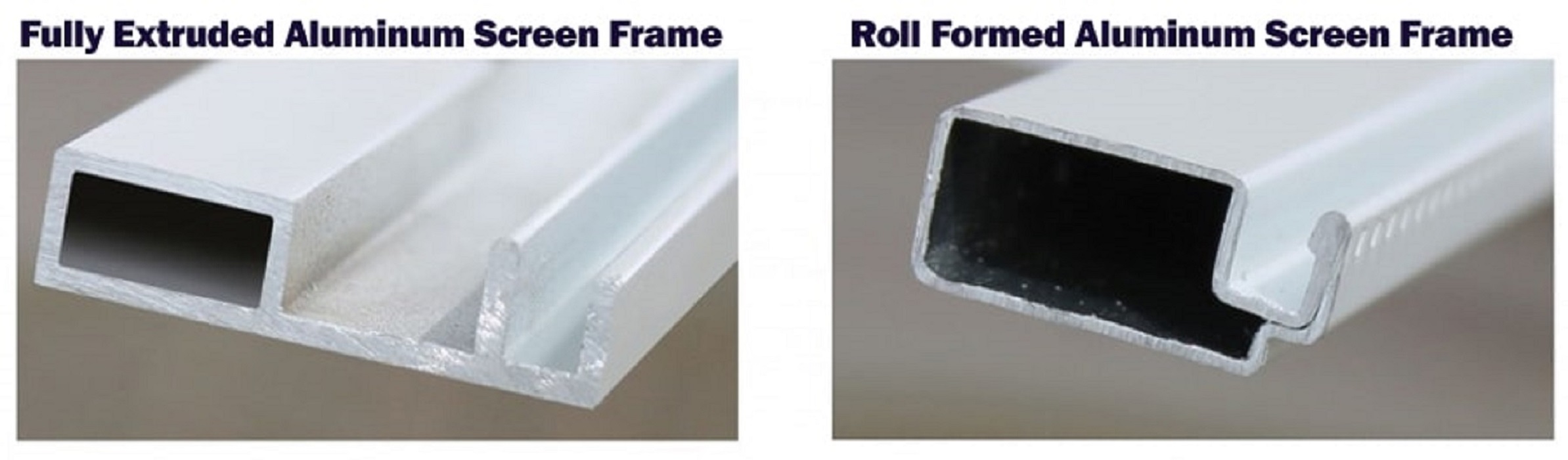

What is the Difference Between Aluminum Extrusion and Roll Forming?

Aluminum Extrusion vs Aluminum Roll Forming

Roll-forming refers to a type of rolling that constitutes non-stop bending of a long sheet to create a preferred cross-section.

Conversely, extrusion is a process utilized to form objects that have a fixed cross-sectional profile.

One main difference between roll-forming and extrusion is that roll-forming is much faster than extrusion.

Also, roll-forming produces a large amount of quantity in comparison to extrusion.

The advantage of aluminum extrusion over roll-forming is that it allows addition of slots and openings in the beginning of manufacturing process.

Whereas roll-forming only offers this option during the secondary post-process.

Moreover, the dies used in aluminum extrusion are less expensive compared to those used in roll-forming.

This is because roll-forming requires a complex die.

However, you cannot apply extrusion to produce extruded aluminum airfoil with multiple bends.

Therefore, roll-forming is the best choice for a product with multiple bends in them.

Lastly, extruded aluminum airfoil tends to have more materials, which helps in enhancing its strength. This is not the case when you use roll-forming.

At Wellste, we have all systems in place to ensure we produce the best grade of aluminum airfoil extrusion.

Whether you want aluminum extrusions or aluminum profiles, we offer a range of finishing options for your specific needs.

Contact us today for all your aluminum airfoil extrusion needs.