6061 and 7075 aluminum alloy are two common aluminum alloy materials, the regular usages are aerospace, automobile, bicycle, and construction.

These two aluminum alloy materials have obvious differences in chemical composition, mechanical properties, processing performance, etc.

Each alloy material also has its unique advantages and weak points.

How to tell the difference between 6061 and 7075 aluminum?

With years of industry experience, Wellste will make a detailed 7075 VS 6061 aluminum materials comparison.

Also, provide professional advice to ensure you choose the most suitable aluminum alloy material for your aluminum extrusion profiles.

1. Overview of 7075 and 6061 Aluminum

1.1 6061 Aluminum

6061 aluminum alloy has superb processability and it is a heat-treatable alloy. Its flexibility makes it suitable for intricate components, as it provides exceptional resistance to anodizing, notable strength, and corrosion resistance.

These features make it a preferred choice for manufacturing high-strength components in the aerospace, automotive, and bicycle industries. Furthermore, this alloy exhibits good weldability and machinability.

6061 aluminum profile extrusion cooling method is water cooling(T6). Except for aluminum extrusion profiles, 6061 alloy also use for aluminum plates.

1.2 7075 Aluminum

7075 aluminum alloy is light in weight, high in hardness, good in wear resistance and good in corrosion resistance.

It is suitable for preparing parts requiring high strength, such as aerospace parts, aircraft parts and racing car parts.

7075 aluminum alloy application relates to various performance requirements.

During the preparation and processing, ensure excellent performance and reliability, the alloying elements and the heat treatment process need strict control.

1.3 6061 VS 7075 Aluminum

When you choose extrusion profiles between 6061 aluminum alloy and 7075 aluminum alloy, you need to consider many factors. Such as the hardness, strength, corrosion resistance, processability, and even budget of the alloy material.

Wellste has compiled the most complete parameter table for you, giving you an intuitive comparative analysis, please refer to the table below:

1.4 Density

6061 aluminum density is 2.70g/cc, and 7075 aluminum density is 2.81g/cc.

This heightened density is a key aspect underlying the exceptional strength of the 7075 aluminum alloy.

1.5 Hardness

7075 alloy is harder than 6061. 6061 aluminum hardness O temper is about HB 30-35, T6 temper hardness is about HB 90-95.

7075 aluminum hardness O temper is HB 60, T6 temper hardness is HB 150.

1.6 Strength

Is 6061 or 7075 aluminum stronger?

7075 aluminum strength is stronger than 6061 aluminum alloy, and its strength is no less than steel, about 1.5-2 times 6061.

7075 superior strength become an ideal material in many fields, especially in applications that need to withstand high stress and load.

Compared with 6061 aluminum strength, it also shows better ability in resisting bending deformation.

1.7 Durability

7075 aluminum alloy is superior in durability to 6061 due to its high strength.

The strength close to steel, allows it to maintain structural integrity and stability in the face of high stresses and loads.

The ability to maintain its performance over a long period of time in wet, corrosive environments prolongs its service life.

1.8 6061 vs 7075 Corrosion Resistance

6061 aluminum corrosion resistance is better than 7075 aluminum alloy without any heat treatment. especially in some common environments.

7075 aluminum corrosion resistance also displays corrosion resistance, however, it is vulnerable to certain corrosive agents, resulting in localized corrosion.

1.9 Machinability

In order to adapt to different processing requirements, it is very important to choose suitable materials.

6061 aluminum machinability is well, and it is a machinability and form aluminum alloy. It has high plasticity and enforceability, mainly suitable for various processing methods, such as milling, stamping, forging, bending and welding, etc.

Low hardness makes 6061 aluminum alloys easy to cut and form, and also can machining over a relatively wide temperature range.

In comparison, aluminum alloy 7075 can be a bit challenging.

Due to its high strength and hardness, 7075 aluminum alloys may require greater cutting forces and machining efforts. This can lead to faster tool wear and add cost and time to the machining process.

In summary, 6061 aluminum alloy has good machinability in terms of processing performance and is suitable for various processing methods.

7075 aluminum machinability may be challenging in terms of processing performance, but it can still be processed by appropriate processes and methods. Machined to meet its needs in high strength applications.

1.10 Weldability

7075 aluminum alloy is more difficult to weld than the 6061 aluminum alloy.

6061 aluminum has good welding performance, it is suitable for many common welding methods. Including argon arc welding (TIG welding), gas shielded welding (MIG welding), and resistance welding.

This is because the 6061 aluminum alloy has high plasticity and workability. it can flow and fill the weld well in the molten state, so as to obtain good welding quality.

Generally speaking, 7075 aluminum weldability may be slightly poor.

Due to its high strength and hardness, it is more likely to crack and deform during welding. Aluminum 7075 makes welding relatively difficult.

In summary, 6061 aluminum weldability is better, it is easier to weld and is suitable for many common welding methods.

7075 aluminum alloy welding performance is poorer, requiring more careful welding operation and control to ensure welding quality and structural stability.

1.11 Surface treatment

It is easier to anodize 6061 aluminum, while 7075 aluminum is unstable when anodized.

6061 aluminum is relatively easy to carry out various surface treatments, such as anodizing, electrophoretic coating, spraying, mechanical polishing, etc.

Anodizing is the most common surface treatment type, it creates a strong oxide layer to provide protection and improves appearance. This oxide layer has many colors, making 6061 aluminum have a wider range of applications.

7075 aluminum surface treatment performance may be poor.

Due to its high hardness and strength, it may not be easy to carry out certain surface treatments. For example, due to the higher hardness, it required higher current and voltage when anodizing. Only that is to ensure a uniform and stable oxide layer.

In general, 6061 aluminum alloy is relatively good in surface treatment performance. It is suitable for a variety of surface treatment methods and can machining to improve appearance.

7075 aluminum alloy surface treatment performance is poor than 6061. But it can still meet some surface treatment requirements by appropriate treatment methods, especially in applications that require high strength and high performance.

1.12 Heat Treatment Tempers

6061 aluminum alloy can be used in a variety of different heat treatment states, including T4, T6 and T651.

Features: T6 state is the most commonly used heat treatment state, with high strength and excellent welding performance. In the T6 temper, 6061 alloy has good corrosion resistance and is suitable for various engineering and structural applications. In comparison with T6, T651 is more stable, avoiding residual stress issues.

Heat treatment state: 7075 aluminum alloy is usually used in T6 state, which is also the most common heat treatment state.

Features: 7075 alloy has extremely high strength. However, its weldability is poor and it is prone to hot cracks. Due to its high strength, 7075 alloy can be challenging to machine in some cases.

In general, 6061 and 7075 aluminum alloys have different advantages in different application scenarios.

6061 is suitable for situations that require corrosion resistance and better welding performance, while 7075 is suitable for occasions that require extremely high strength and rigidity, but attention should be paid to its difficulty in welding and processing.

When selecting the appropriate material, decisions need to be made based on specific project needs and requirements.

1.13 Cost

On the other hand, considering the cost of materials is also an important factor. Under normal circumstances, 6061 aluminum price is about 20~40% cheaper than 7075. This is mainly due to several reasons.

The first is the difference in material composition. zinc and copper content will increase the strength and hardness of the alloy, thereby improving its performance.

However, this may also lead to an increase in production costs, so 7075 aluminum cost is usually relatively high.

Secondly, in terms of production cost. due to the higher strength and hardness, 7075 aluminum manufacturing is more challenging and require stricter process control and equipment.

Furthermore, regarding the market demand and supply situation. if the 7075 aluminum alloy demand is higher and the supply is scarce, its price may rise. In contrast, if 6061 aluminum alloy is sufficient, 6061 aluminum cost may be relatively stable. that is due to the relationship between supply and demand.

Finally, consider the application. Due to its high strength, 7075 aluminum alloy usage is high performance fields, such as aerospace, military and high-speed vehicles. These high-end applications are willing to pay a higher price, so the 7075 aluminum price may be relatively high.

It is important to note that market conditions and prices may change over time, they affect various factors. If you need to obtain the latest price information, we recommend you consult with local metal suppliers, manufacturers, or market professionals.

1.14 Applications

Owing to its elevated strength and remarkable corrosion resistance, aluminium alloy 7075 applications are widespread.

Industries like aerospace, arms production, racing, and bicycle components require durability and long-lasting quality

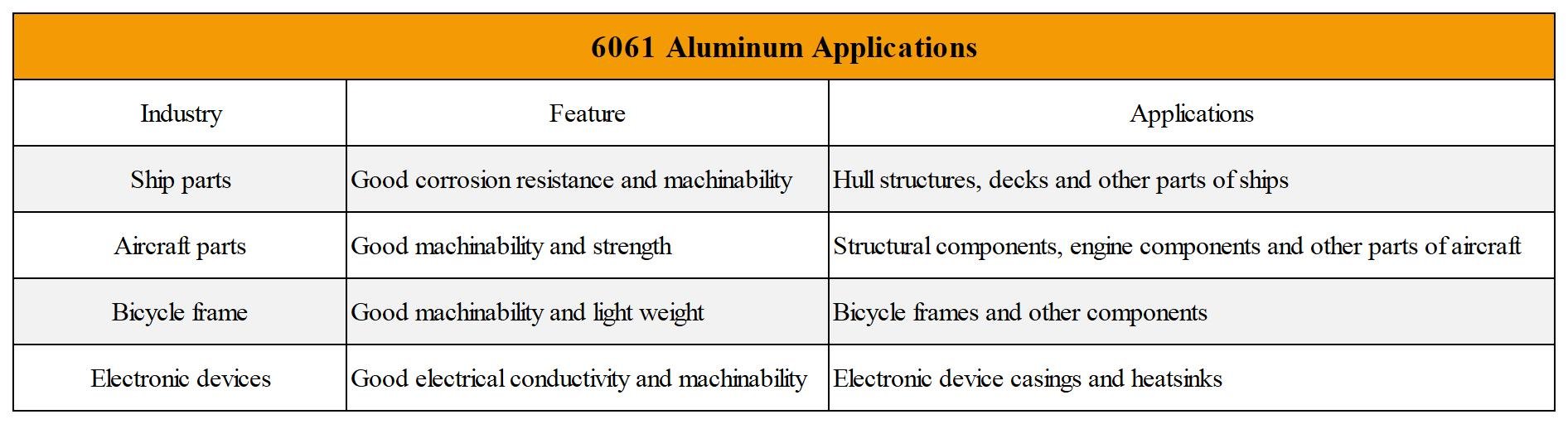

The 6061 aluminum alloy is often used in areas needing good workability and corrosion resistance, like aircraft parts, marine gear, bike frames, and electronics.

In summary, 7075 and 6061 aluminum alloys have significant differences, spanning aspects of strength, workability, corrosion resistance, applications, and cost.

If you can’t decide which alloy to use, just consult Wellste experts, we are glad to give you some advice.

2. 6061 VS 7075 Aluminum: Chemical Composition

The following is Wellste specific analysis table, which includes chemical composition, mechanical properties, thermal energy, processing properties, etc.

Finally, Wellste teaches you how to choose the most suitable alloy grade for your application.

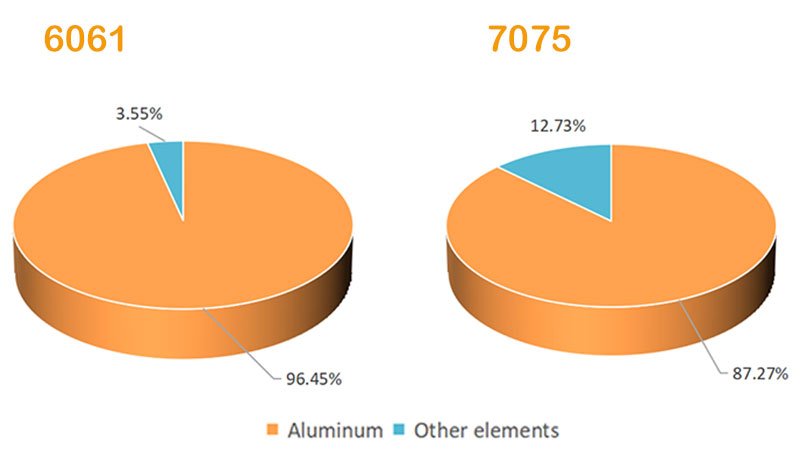

2.1 6061 Aluminum Composition

6061 aluminum contains a low other metals proportion, with magnesium and silicon as the main alloy, and a low proportion of components.

If you want to increase the strength, you can add a small amount of copper or zinc.

2.2 7075 Aluminum Composition

7075 aluminum contains 6% zinc as the main alloy, it also adds magnesium and copper alloys according to specific usages. so that to further improve its performance.

2.3 6061 VS 7075 Aluminum Composition

Regarding chemical composition, the primary contrast between 6061 and 7075 resides in distinct alloying elements within the aluminum matrix. Notably silicon, zinc, magnesium, and copper.

Different amounts of these elements determine the aluminum alloy’s properties such as strength, hardness, and corrosion resistance.

6061 aluminum has more silicon and magnesium, making it easier to machine and weld.

On the other hand, 7075 aluminum has more zinc and copper, giving it greater strength and hardness but possibly reducing its ease of processing and welding.

3. 6061 VS 7075 Aluminum: Mechanical Properties

3.1 6061 Mechanical Properties

6061 mechanical properties are good, it is easy to weld, and very suitable for aluminum extrusion materials. It is very friendly to surface treatment, whether it is electroplating or oxidation, the effect is very good.

6061 is also corrosion resistant and well suited for requiring relatively high strength, good processability, and high elongation at break applications.

3.2 7075 Mechanical Properties

7075 mechanical properties’ main advantage is high strength and hardness. and its processing performance is poorer than that of 6061, especially its welding performance and anti-corrosion performance.

3.3 6061 VS 7075 Mechanical Properties

The following chart is a detailed comparison: 7075 VS 6061 mechanical properties.

3.4 Fatigue Strength

Due to 7075 aluminum alloy having high-strength properties. it is better than 6061 aluminum fatigue strength. It exhibits excellent fatigue resistance when subjected to cyclic loads and repeated stresses.

Since the 7075 aluminum fatigue strength is better, the 7075 aluminum extrusions have a long service life, prolonging the time between precision instrument inspections and reducing maintenance costs.

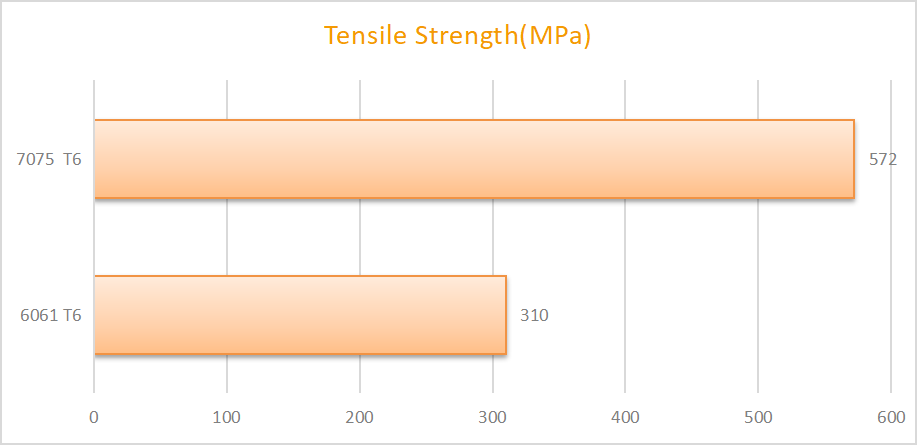

3.5 Tensile strength

7075-T6 aluminum Tensile strength is 572MPa, and 6061 aluminum Tensile strength is 310MPa.

The 2-fold difference means that 6061 is easier to form, while 7075 can withstand greater tensile strength. Therefore, it is more suitable for those who require higher strength applications.

3.6 Yield strength

Choosing the right aluminum alloy depends on the particular application needs, and requires comprehensive yield strength consideration, and other performance indicators.

Yield strength is the stress that a material bears when it begins to produce visible plastic deformation. and it is an important indicator for evaluating the strength and deformation characteristics of a material.

7075 aluminum Yield strength is 503 MPa/73,000 psi, 6061 aluminum Yield strength is 276 MPa/40000 psi.

7075 T6 aluminum Yield strength is about double that of 6061, making it ideal for high-strength applications like aerospace, military, and high-speed vehicles.

Meanwhile, 6061 aluminum, with its lower yield strength, is suited for general use and less demanding parts, such as basic mechanical components and building materials.

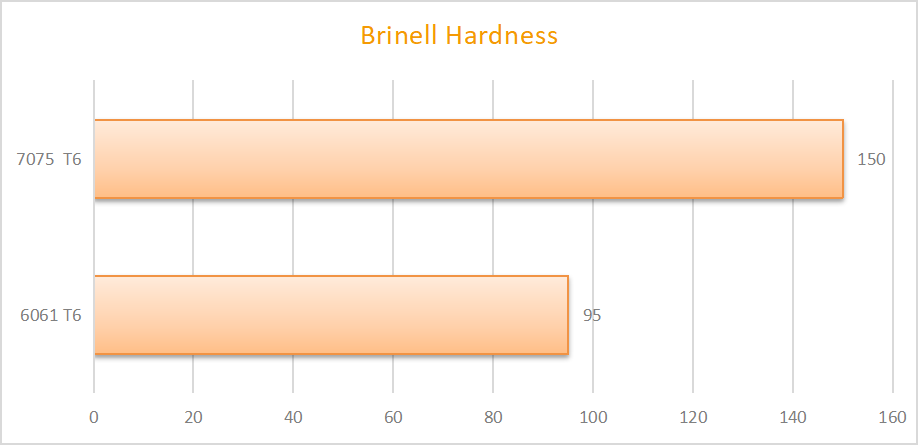

3.7 Brinell Hardness

Hardness measures a material’s capacity to withstand scratching and deformation.

Commonly employed to assess the material’s resistance to wear and overall durability.

7075 aluminum Brinell Hardness is 150, and 6061 aluminum Brinell Hardness is 95.

7075 aluminum alloy high hardness makes it excellent at carrying loads, resisting wear, and maintaining shape stability.

In contrast, 6061 aluminum alloy has a lower hardness and is suitable for some general applications. It requires lower hardness, such as general mechanical parts and building materials.

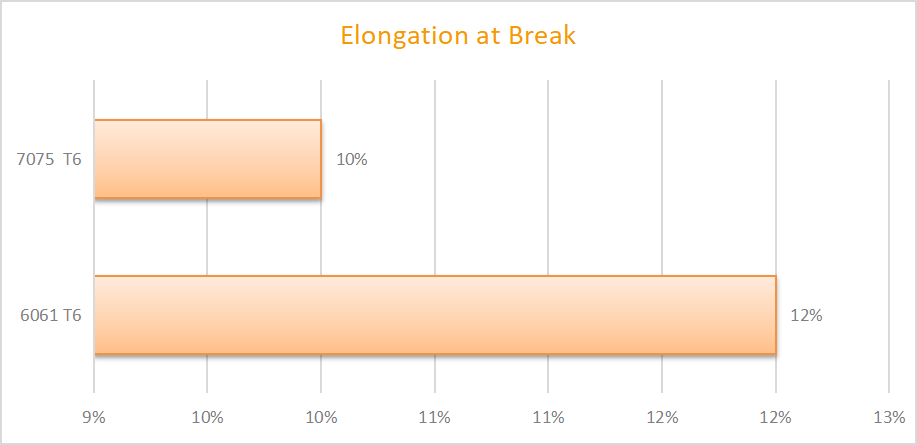

3.8 Elongation at Break

6061 aluminum Elongation at break is 12%, 7075 aluminum Elongation at break is 10%.

Elongation at break shows how much a material can stretch before breaking, indicating toughness and ductility.

More elongation means better ability to stretch under stress, preventing sudden fractures from impact or stress.

We can see from the above data, 6061 aluminum alloy generally has a higher elongation at break. The elongation at break of 7075 aluminum alloy is relatively lower than 6061.

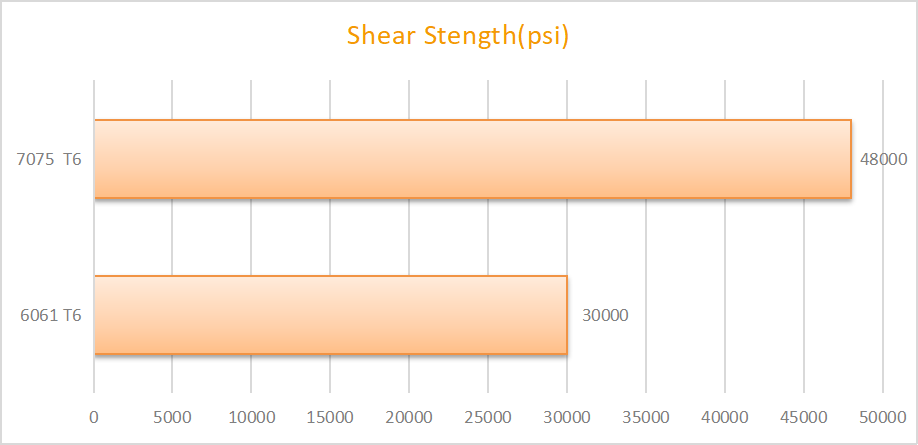

3.9 Shear Strength

Shear strength refers to the material resistance when it is subject to a shear force.

It usually uses to evaluate the material performance in applications such as cutting and shearing.

7075 T6 aluminum Shear Strength is 331 MPa/48000 psi, 6061 T6 aluminum Shear Strength is 207 MPa/31000 psi.

7075 aluminum shear strength means that it can withstand greater forces when subjected to shear stress. It is more suitable for those applications that require high strength and high performance.

In contrast, 6061 aluminum alloy has low shear strength and is suitable for some general applications that require low shear strength.

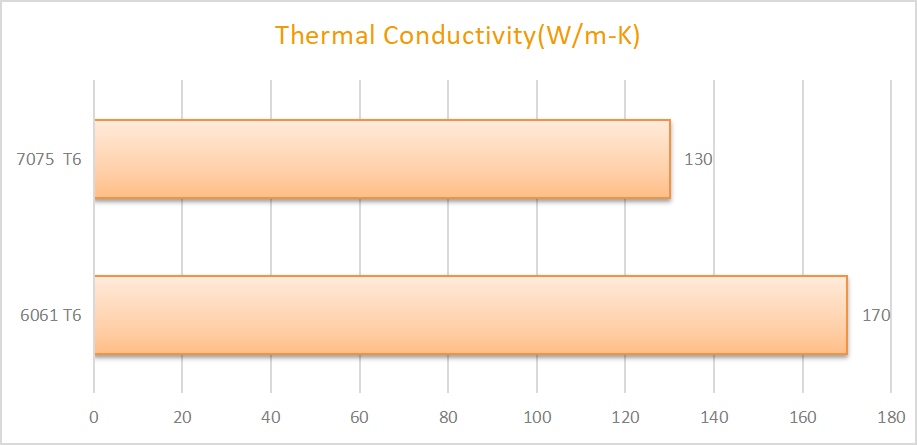

3.10 Thermal Conductivity

6061 aluminum thermal conductivity is 170W/m-K, 7075 aluminum Thermal Conductivity is 130W/m-K.

This indicates that 6061 aluminum conducts heat better than 7075.

High thermal conductivity materials excel in transferring and dissipating heat quickly. offering advantages in applications like using aluminum alloy profiles as heatsinks.

For instance, 6061 exhibits better cooling performance than 7075.

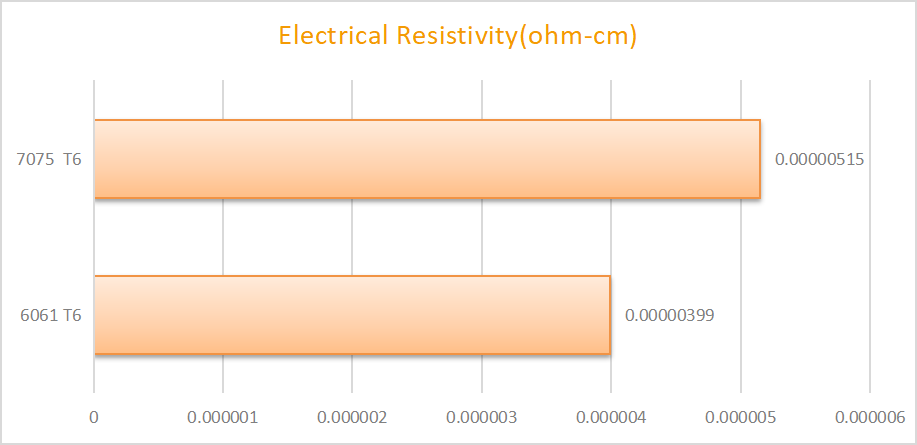

3.11 Electrical Resistivity

Materials with lower resistivity are generally better at conducting electricity, allowing them to conduct electricity more efficiently.

6061 aluminum alloy electrical resistivity is lower than 7075 aluminum alloy. Therefore, the conductivity of 6061 aluminum alloy is better than that of 7075.

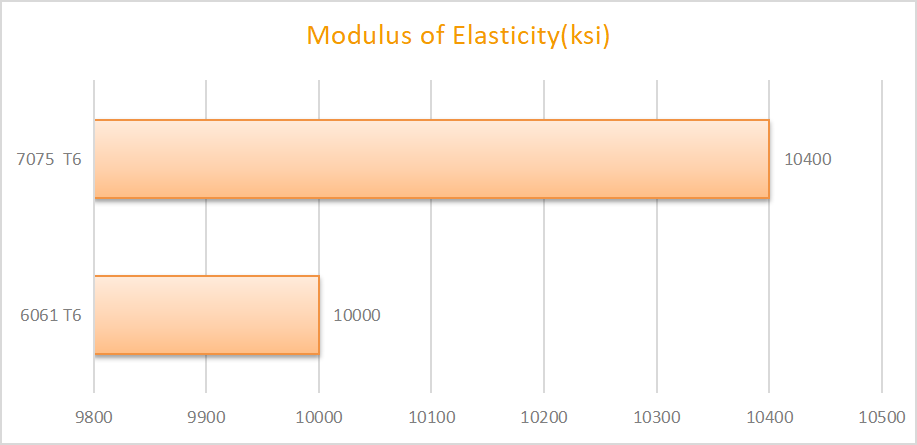

3.12 Modulus of Elasticity

6061 aluminum Modulus of Elasticity is 10000ksi, 7075 aluminum Modulus of Elasticity is 10400ksi.

Modulus of elasticity variations impact material strain, deformation traits, and elastic recovery under stress.

The modulus of elasticity of 6061 aluminum alloy is slightly lower than that of 7075 aluminum alloy. So, 6061 does not respond as elastically as 7075 when stressed.

3.13 Melting Point

6061 aluminum melting point is 582 – 651.7°C, 7075 aluminum melting point is 477 – 635°C.

7075 aluminum has a slightly lower melting point. Therefore, 6061 alloy is more resistant to high temperatures than 7075 alloy.

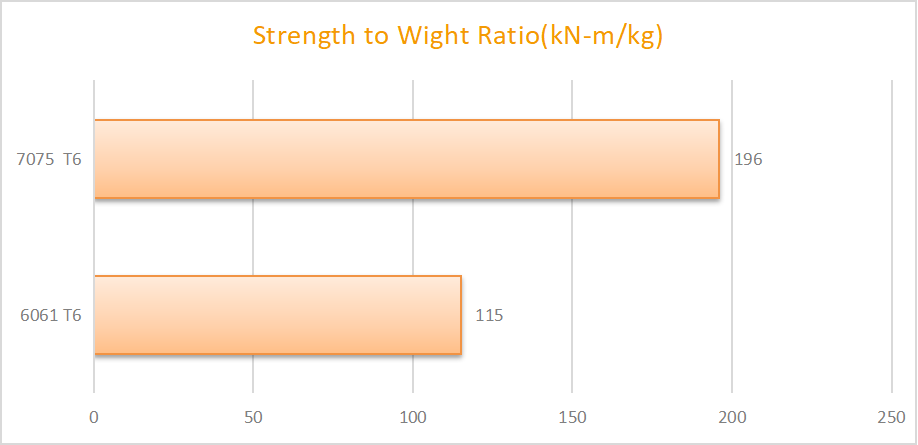

3.14 Strength to Weight Ratio

Strength to weight ratio = tensile strength/density.

6061 aluminum alloy Strength to weight ratio ≈ 276 MPa / 2.70 g/cm³ ≈ 102.22 MPa/g/cm³.

7075 aluminum alloy Strength to weight ratio ≈ 524 MPa / 2.81 g/cm³ ≈ 186.48 MPa/g/cm³.

Through these calculations, we can see that the 7075 aluminum alloy strength to weight ratio is higher than 6061 aluminum alloy. It means that at a given density, 7075 aluminum alloy is lighter relative to its strength performance.

4. Tips on choosing the right alloy for your project

4.1 Determine Your Applications

Both 7075 and 6061 aluminum alloys have a wide range of applications. We select them according to specific application requirements and material performance requirements. Here are some suggestions for you.

6061 aluminum is apply for tubing, heatsinks, and so on, 7075 aluminum is often used for angle, tube, and other aircraft aluminum extrusion.

4.2 Consider The Budget And Availability

Commonly, 7075 aluminum alloy is more expensive than 6061.

In addition, many manufacturers have a MOQ limit. So price and MOQ are also factors you have to consider.

4.3 Evaluate Machinability

Which is better 6061 or 7075 aluminum? 6061 aluminum machinability performance is better than that of 7075. In terms of extrusion, weldability, surface treatment, and corrosion resistance, it is better than 7075. If your product needs to processing, Machinability is an important factor for you to consider.

4.4 Consider Your Surface Treatment

Compared with 7075, 6061 is more corrosion-resistant and easier to anodize.

If your product requires both aesthetics and corrosion resistance, 6061 is your best choice.

4.5 Check For Industry Or Regulatory Standards

The industry standards of different countries may be different. Wellste recommended you to check your country industry standard documents.

According to your product classification, you can distinguish the main performance and effect. so that it is more convenient to choose the aluminum alloy grade that meets your needs.

4.6 Consult With An Expert Or Supplier

If you still don’t understand what is the difference between 6061 and 7075 aluminum, Wellste recommend you consult industry experts, they will recommend the most suitable aluminum grades based on their own experience.

Even providing you with relevant case references, help you carry out your projects faster.

5. Conclusion

In summary, is 7075 aluminum better than 6061? No, both 6061 and 7075 have good performance and are suitable for different applications.

6061 can basically meet general industrial manufacturing requirements. the 7075 use in more demanding applications.

Wellste is a professional manufacturer that excels in assisting you to select the most appropriate alloy for your specific needs. Our expertise extends across a wide spectrum of industries, ensuring that you receive expert guidance tailored to your application.

Whether it is custom aluminum extrusion or custom aluminum fabrication, Wellste completes the aluminum products under one roof, we will meet your high quality requirements.

In addition to quality products, Wellste also focuses on providing excellent service. We have a professional after-sales team to provide technical support and solutions for customers at any time.

Whether it is product installation and use problems or after-sales maintenance, Wellste can respond in a timely manner and actively solve customer needs.