Do you know the difference between 7075 and 7005 aluminum? Let Wellste take you deep into this topic.

What’s the advantages of Aluminum? Where is aluminium used in everyday life?

Aluminum density is only about 2.7×10³ kg/m³, which is roughly 1/3 of steel, copper, or brass.

Due to its lightweight material, aluminum is common use for the manufacturing of land, sea, and air transportation vehicles. such as cars, trains, subways, ships, planes, rockets, and spacecraft, to reduce weight and increase payload capacity.

What is 7000 series aluminium?

7000 series aluminum is an aluminum alloy mainly composed of zinc and sometimes containing small amounts of magnesium, copper or lead.

7000 series aluminum advantage is that it has a high hardness close to steel, but it is much lighter than steel.

7000 series aluminum is famous for its good yield, high strength, toughness, and good resistance to fatigue.

What is 7000 series aluminum used for?

7000 series makes ideal for industries such as aerospace, automotive, and manufacturing.

It is frequently application for critical components such as load-bearing structures, landing gear, propellers, and spacecraft for airplanes, and rockets.

The unique aluminium 7000 series properties enable it to withstand extreme operating conditions, making it a dependable material for the aerospace industry.

Due to their lightweight, durability, and good corrosion resistance, 7 series aluminum also use for computer parts, smartphones, and other consumer electronics.

7000 series aluminum is popular used in Apple phones,apple watch, and computers enclosure, and the enclosures of Xiaomi products.

They also use to produce antennae, including TV antennae and radar construction. Some countries even use 7-series aluminum alloys to construct pylons for power lines.

Among the many grades of 7 series aluminium, 7075 aluminum and 7005 aluminum have the highest quality properties.

These alloys possess excellent strength-to-weight ratios and can strengthen further by undergoing a heat treatment process.

Today, Wellste will explain the difference between 7075 aluminium alloy and 7005 aluminium alloy from Component Elements Properties, Mechanical Properties, and Thermal Properties.

Composition Properties 7005 VS 7075

For 7 series aluminium alloys, zinc accounts for a relatively high alloy composition. magnesium and copper also account for a certain proportion.

As we can see in the below “Chemical Composition of Deformed Aluminum and Aluminum Alloys” chart.

These are 7005 and 7075 aluminum chemical composition found in the GB/T 3190-2008 standard.

Zinc, magnesium, and copper in 7075 aluminium is higher than that in 7005. especially the zinc element, which can even reach 6%.

Compared to other series of aluminum alloys, both 7005 aluminium alloy and 7075 aluminium alloy have higher alloy proportions, making them more difficult to machine.

In particular, 7075 aluminum alloy composition is higher than 7005, so it is generally not weldable.

The biggest difference between 7005 and 7075 aluminum is that “7005 can welding“.

Among the aluminium 7 series,only 7005 can use for bike frames. other grades of aluminum cannot because they are not good in weldability.

7075 cannot use for bike frames, but it is more suitable for one-piece molded components such as chainrings.

Mechanical Properties between 7005 and 7075

In addition, there is also a significant difference between 7005 aluminium alloy and 7075 aluminium alloy, we can see the 7005 and 7075 mechanical properties comparison below.

7075 aluminum has poor processability because it contains a lot of zinc elements. Zinc makes 7075 alu difficult to weld, This characteristic decides that it is often for parts of CNC machines.

How strong is 7075 aluminum?Is 7075 aluminum stronger than steel?

Hardness is a very important parameter in mechanical properties.

Look at the chart, we can find that the 7075 alloy hardness is obviously much higher than 7005. 7075 hardness can reach up to 150HB, significantly greater than 94HB of 7005.

7005 is a lightweight aluminum alloy with lower strength than 7075.

Although 7075 alloy is light in weight, it is a high-strength metal, and its strength is similar to steel.

The difference in mechanical properties makes 7005 and 7075 also have different uses.

7005 aluminum alloy main usage is in the manufacture of bicycle or car frames, auto parts, etc.

7075 aluminum alloy main usage is manufacture aircraft structural parts, engine parts, satellites, and so on.

Thermal Properties of 7005 & 7075

Aluminum 7075 belongs to Al-Zn-Mg-Cu super duralumin. Its characteristic is that even after solution treatment, it still has good plasticity.

And at the same time maintain a good heat treatment effect.

Aluminium alloy 7000 series has good mechanical properties.

It is easy to process, has good wear resistance, good anodic reaction performance, high strength, and heat treatment.

In addition, 7005 aluminum alloy can do CNC machining, and after machining, 7005 aluminum alloy will not deformation and distortion.

7075 melting point range is 477-635℃. Since the 7005 aluminum alloy elements are relatively lower than 7075. the melting point is relatively high, and the 7005 melting point is 607-643℃.

In short, although 7005 and 7075 aluminum alloys are both high-strength aluminum alloys, their specific uses are slightly different, and appropriate materials need to be selected according to actual conditions.

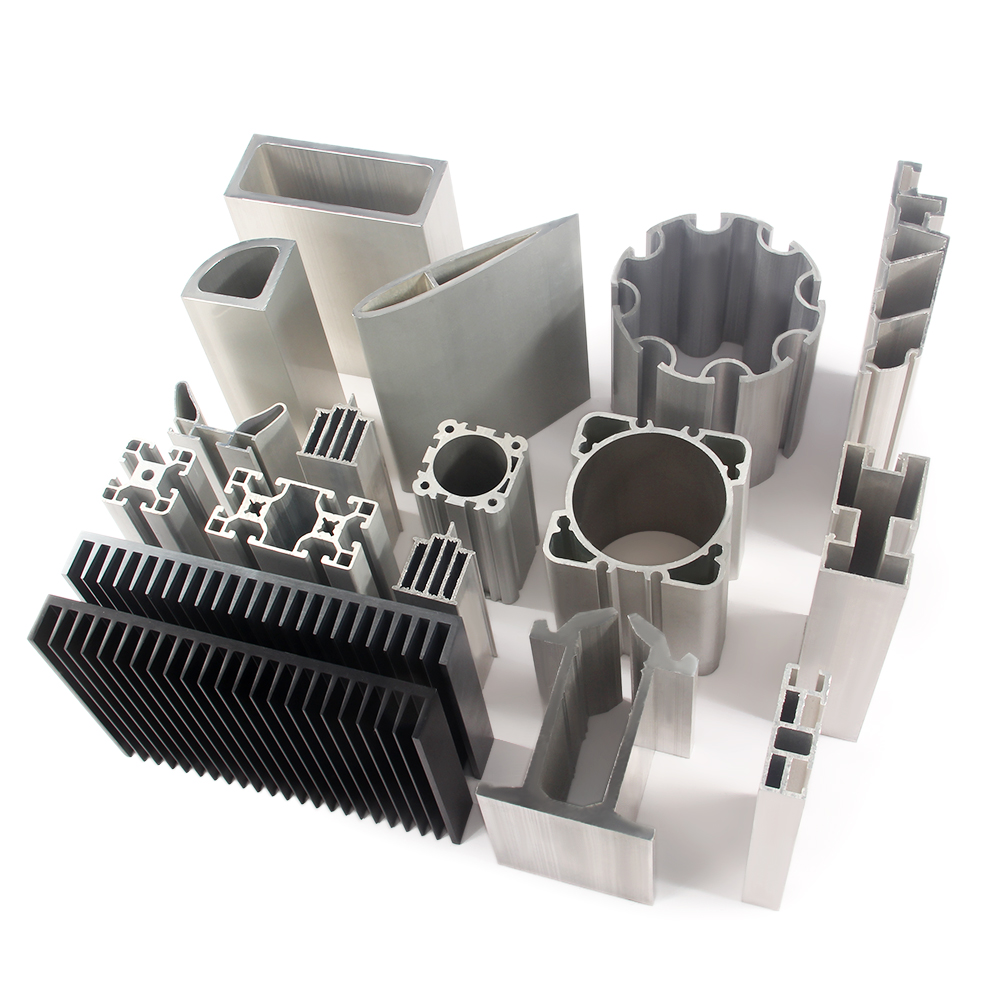

As a professional manufacturer of aluminum profiles in China, Wellste has won the trust of customers with its multi-variety management.

The long-term stock of various types of aluminum raw materials, such as: 6063/6060/6061/6005/6463/6082/6005A/6351/2024/2A12/7075/7005/7003/7021/7020/6013/1060/1070/1100 /3003/5052/5A02/5754/5083/6101/6101B/5025/5052/5072/5082/5083, etc.

Common specifications are in stock, and special specifications can customize.

Wellste aluminum profile products are reliable in quality and competitive in price. We can provide customers with material samples and material certificates for testing and confirmation for free.

We manufacture 7075 aluminum profiles like 7075 Aluminum Angle Extrusion,7075 Aluminum Tube, Aerospace Aluminum Extrusion, and other Custom Aluminum Extrusions.

Welcome your inquiry!