Wellste has a team of engineers and technicians, They work closely with our clients to understand their specific requirements, so that Wellste could provide them with best solutions.

Our production capacity is flexible and can be adjusted to meet the changing needs of our clients.

Custom Aluminum Profiles Design phase communication

On November 22, 2021, Wellste received an custom aluminum extrusions inquiry from a Swiss battery manufacturer, who has many years of experience in designing and manufacturing batteries for many automotive companies in Switzerland.

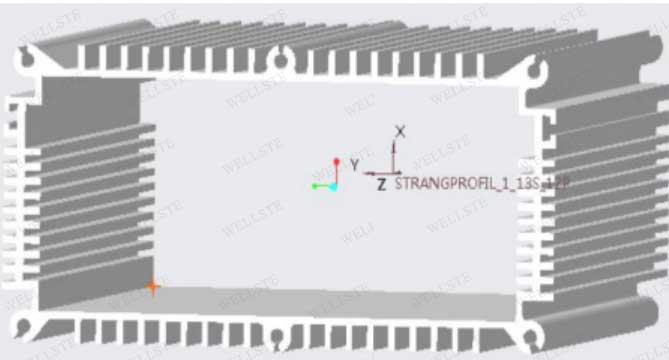

The customer inquired for an aluminum PCB enclosure for battery protection: aluminum one-piece housing, the following is the first design of the customer.

Preliminary Custom Aluminum Extrusions Quotation

On 22.10.2021, after an evaluation by our engineers, we confirmed that we could produce this extruded aluminum enclosure and quoted a price, The customer very appreciated our efficiency after received the quotation.

Custom Aluminum Profiles Technical negotiations

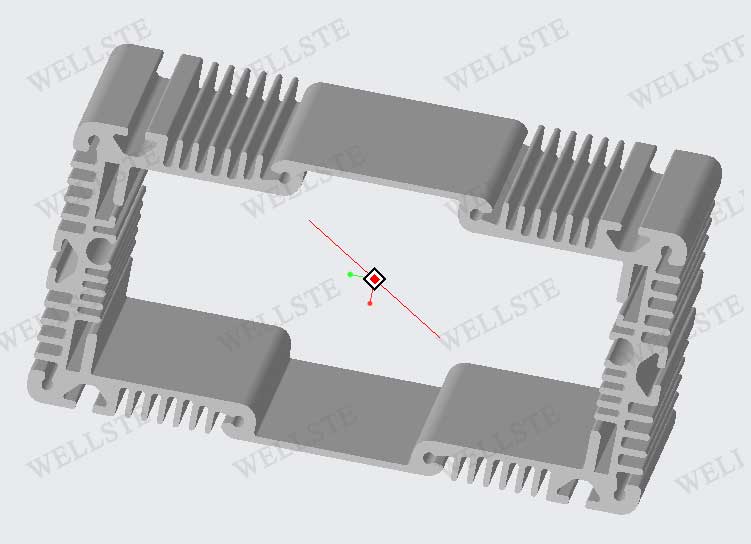

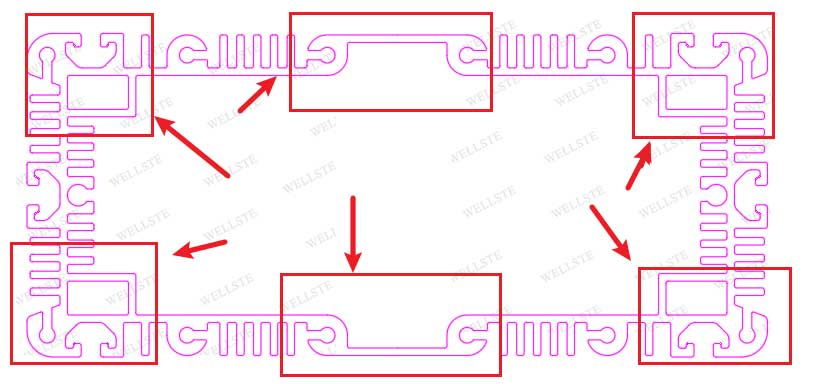

2021.12.13 The customer said the whole battery is still in preliminary design, and sent the second version of revised drawings.

This time, the custom aluminum extrusions design has many more teeth than the first version, and the shape is changed greatly.

Our Sales received the updated drawing and quickly sent it to the technical department for evaluation.

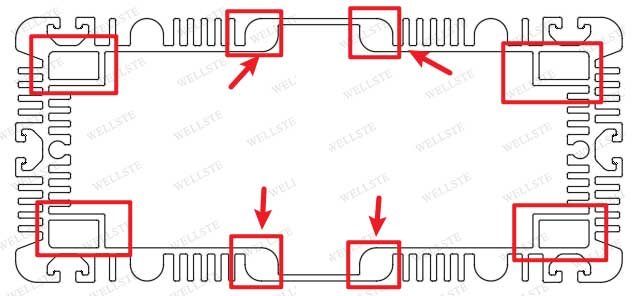

Wellste engineer pointed out that since this is a large extruded aluminum enclosure, 100*250mm, it will lead to curling of the thin edge during extruding if there are too many openings inside, and proposed the following modification solutions:

Solution 1:

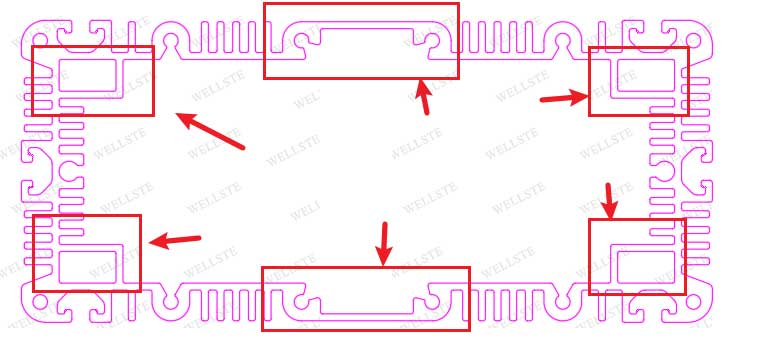

Solution 2:

Solution 3:

The customer communicated with us about their needs after receiving the proposal:

This custom aluminum enclosure needs to be enough space inside to put PCB and battery device, so the surrounding cannot have too much space by the cavity, so the customer will redesign with our production possibilities.

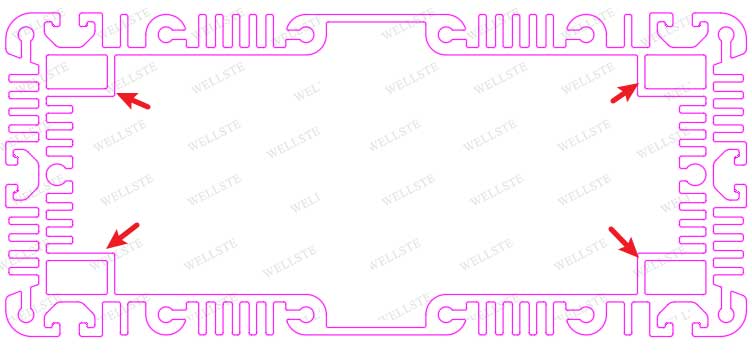

2021.12.23 The customer sent us the third version of the extruded aluminum enclosure drawing, this time the custom aluminum extrusions design is very irregular, Our engineer gave a detailed modification plan after evaluation, basically there is no major problem, but due to the irregular design, we still suggest the customer to change the two sides to a straight wall.

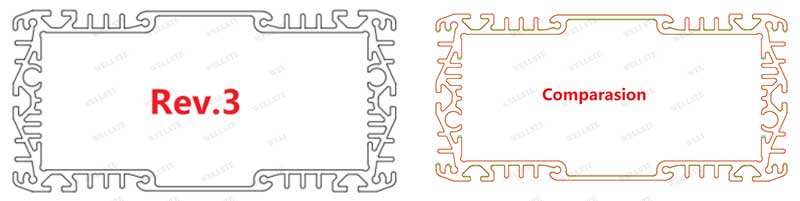

2021.12.30 The customer gave the 4 version of the design after discussion, this time the aluminum extrusion enclosure wall thickness was too thin and easily deformed in extrusion, we suggested that the wall thickness could be thickened.

2022.1.19 After New Year, the customer changed the custom aluminum extrusions wall thickness to 2.8mm, sent the final design and started the production order.

Custom Aluminum Profiles Sample Production

2022.2.25 We finished the aluminum PCB enclosure mold and sent samples to confirm the color and assembly to the customer.

2022.3.20 The customer confirmed the sample, and our company started the production of bulk order.

2022.3.30 The custom aluminum extrusions production and packing are finished, arrange the transportation.

2022.5.1 Customer received the goods

The customer expressed that he was very satisfied with our aluminum PCB enclosure and promised that he would have more demand in the future.

For custom aluminum extrusions, Wellste always receives many projects in the initial design, especially in the application of battery, our company is willing to grow together with these customers to complete the design.

For any quotation, our service will be fast and professional. The success of each production is inseparable from the efforts of both parties, and the Wellste team has always adhered to the business principle of helping customers and making their own achievements, and constantly assisting customers to win the market.

If you have any inquiry, please feel free to contact us at [email protected].