Wellste is a leading custom aluminum extrusion manufacturer based in China since 1996.

With 35 extruding press lines, Wellste specializes in producing custom aluminum extrusion, custom aluminum fabrication, window and door profiles, heat sink profiles,etc.

Today, Wellste shows you a case that how to make custom aluminum extrusions.

Custom Aluminum Extrusions Design phase communication

Date: 17nd Jul 2020

Wellste received an inquiry from a axial flow fans manufacturer. They are looking to custom aluminum extrusions to be used in their components, specifically for guiding airflow through the fan.

The customer mentioned that the red highlighted in the two images cannot be modified because they are crucial for directing air flow through the fan.

Custom Aluminum Extrusions Technical negotiations

- Grade Issue: The customer requires aluminum grade 6063 T6. Considering the large opening of the customer’s profiles, which is easy to deformation during the extrusion process, it is more challenging to control the degree of deformation with T6 hardness. Therefore, we recommend sticking with 6063 T5 grade. The customer has accepted this recommendation.

- Wall Thickness Issue: Similarly, considering the issue of large openings and potential deformation, the thin wall aluminum extrusion current wall thickness is 1.9mm. We propose increasing it to at least 2mm to enable mold production. The customer has also agreed to this adjustment.

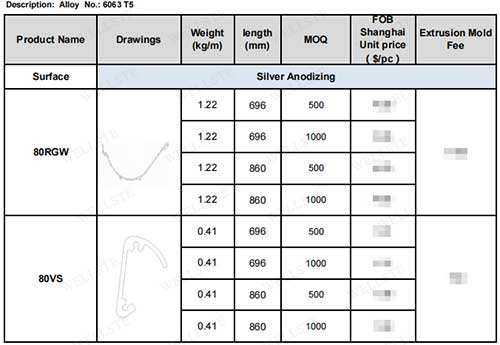

Custom Aluminum Extrusions Preliminary Quotation

Once we have reached a consensus on the technical aspects, we provided the customer with a quotation for their reference.

But, due to the outbreak of the COVID-19 pandemic, the customer’s project was put on hold.

Till to December 9, 2021, the project resumed, and the customer placed an order directly.

Extruded Aluminium Profile Sample Production

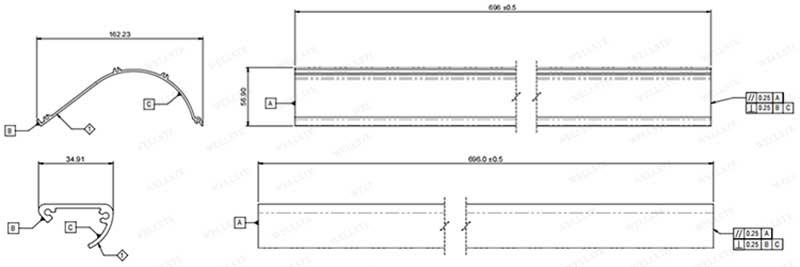

Before production, the customer emphasizes that cutting tolerances, perpendicularity, and parallelism are crucial as the two extruded aluminium profiles, since they need to be assembled together.

Any deviations beyond the specified tolerances can cause assembly issues. We assure the customer that we will provide dimensional inspection reports to ensure compliance with their requirements.

Date: 27nd Dec 2021

we have successfully completed the aluminum extrusions molds and have extruded a few samples:

According to customer requirements, overlap the sample screenshot with the 1:1 printed drawing to detect the shape.

The customer pointed out that this one seems to be a bit out of line with the drawing:

This is because the aluminum extrusion profiles opening is too large, the wall thickness is very thin, and there is a slight deformation during the extrusion process, but this can be corrected by simple manual bending, and this will not affect the installation and use.

The following is our presentation to our customers:

The customer accepts the sample and decides to try the installation first.

Date: 24nd Jan 2022

We finished the sample and shipped it.

After received the samples, the customer provided feedback on a few issues:

- The length tolerance slightly exceeds the allowed range.

- There are issues with verticality, causing unevenness and installation misalignment, as shown in the image.

We will make improvements by using a double-blade cutting machine for bulk production. Additionally, we asked customers to send us the assembled components, which will serve as our inspection criteria before shipping.

In May, the customer sent us the components, and we attempted assembly.

Extruded Aluminium Profile Bulk Production

Date: 16nd Dec 2022

The customer placing the bulk order, we utilized angle measuring instruments to measure right angles. This was done to ensure parallelism and verticality.

Also we try to assemble again to make sure there is no problem.

Custom Aluminum Extrusions Feedback

After received the products, he customer confirmed that there was no problem at all. They are also very satisfied.

Some Thoughts from Wellste

Wellste places great emphasis on continuous improvement and innovation to adapt to market changes and meet customer demands.

We actively listen to customer feedback and incorporate it into product research, development, and production processes, continuously enhancing product quality and service levels.

With this customer-centric approach, Wellste is dedicated to establishing long-term partnerships with clients and providing them with the best solutions and satisfying user experiences.