- Advanced Manufacturing Capabilities

- One-stop Design & Manufacturing Solutions

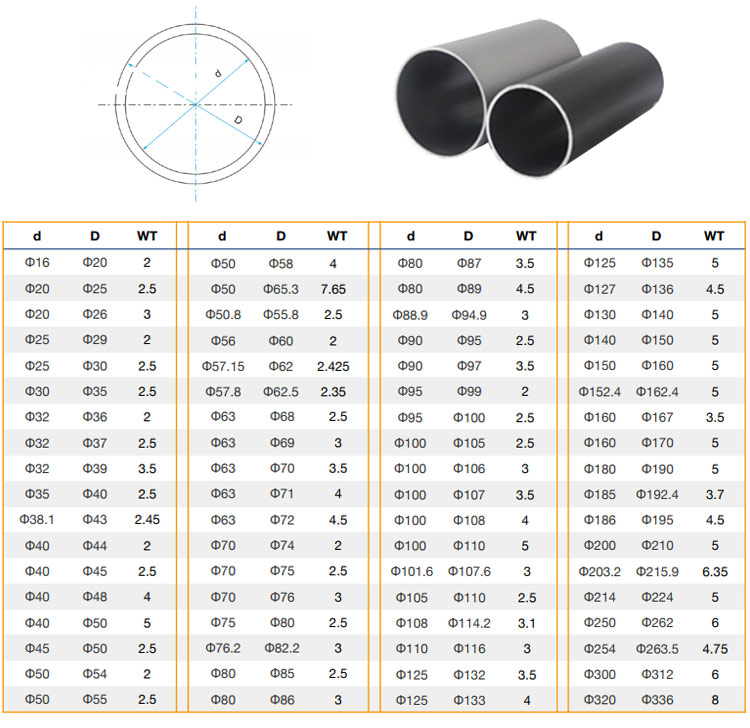

- Standard Existing Size Save Your Initial Cost

- Fast Shipment with a full range of Stock Products

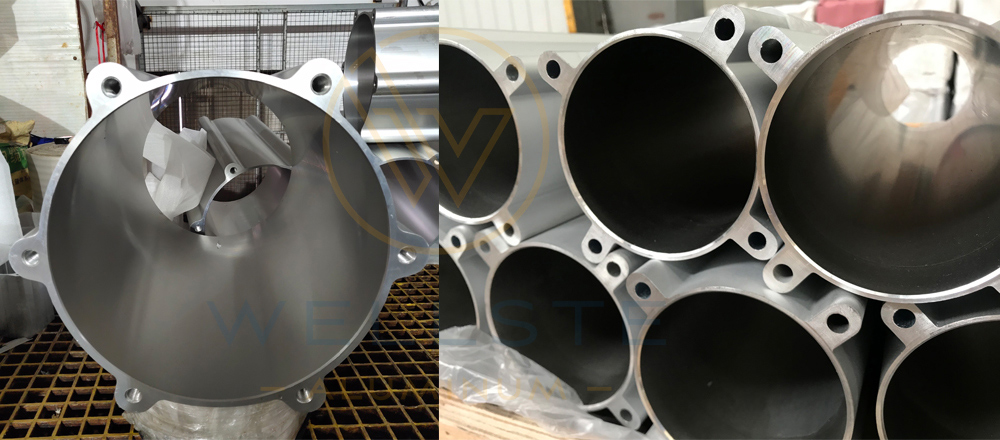

Honed Aluminum Cylinder Tubing

Wellste has a complete set of machine lines and facilities. For 20 plus years, we are proven capable of providing a shorter lead time than our competitors. As a result, we always deliver our products without any delay.

- Visual Check-Up to Eliminate Manufacturing Flaws

- Careful Inspection for Proper and Accurate Dimensioning

- Complete Facilities and Machines for Faster Yet Quality Production

- High-Grade Materials Used and Heat Treated for Maximum Strength

Your Reliable Honed Aluminum Cylinder Tubing Supplier

Wellste honed aluminum cylinder tubing aspect you can trust is its sturdiness. Wellste honed aluminum cylinder tubing possesses reliable durability for any project application.

In fact, Wellste honed aluminum cylinder tubing is easy to handle because there is a reduction in unnecessary installation delays and costs.

Do not hesitate to reach us. Whether you message us to order or only for inquiry, we will gladly accommodate all your concerns.

Fast quote now for a friendly response from our team. Wellste honed aluminum cylinder tubing is one of the best designs of aluminum cylinder tubing.

Our customers trust the performance of honed aluminum cylinder tubing for automotive applications.

There are a lot of benefits that you can get from using honed aluminum cylinder tubing.

In relation to that, Wellste honed aluminum cylinder tubing is very light in weight.

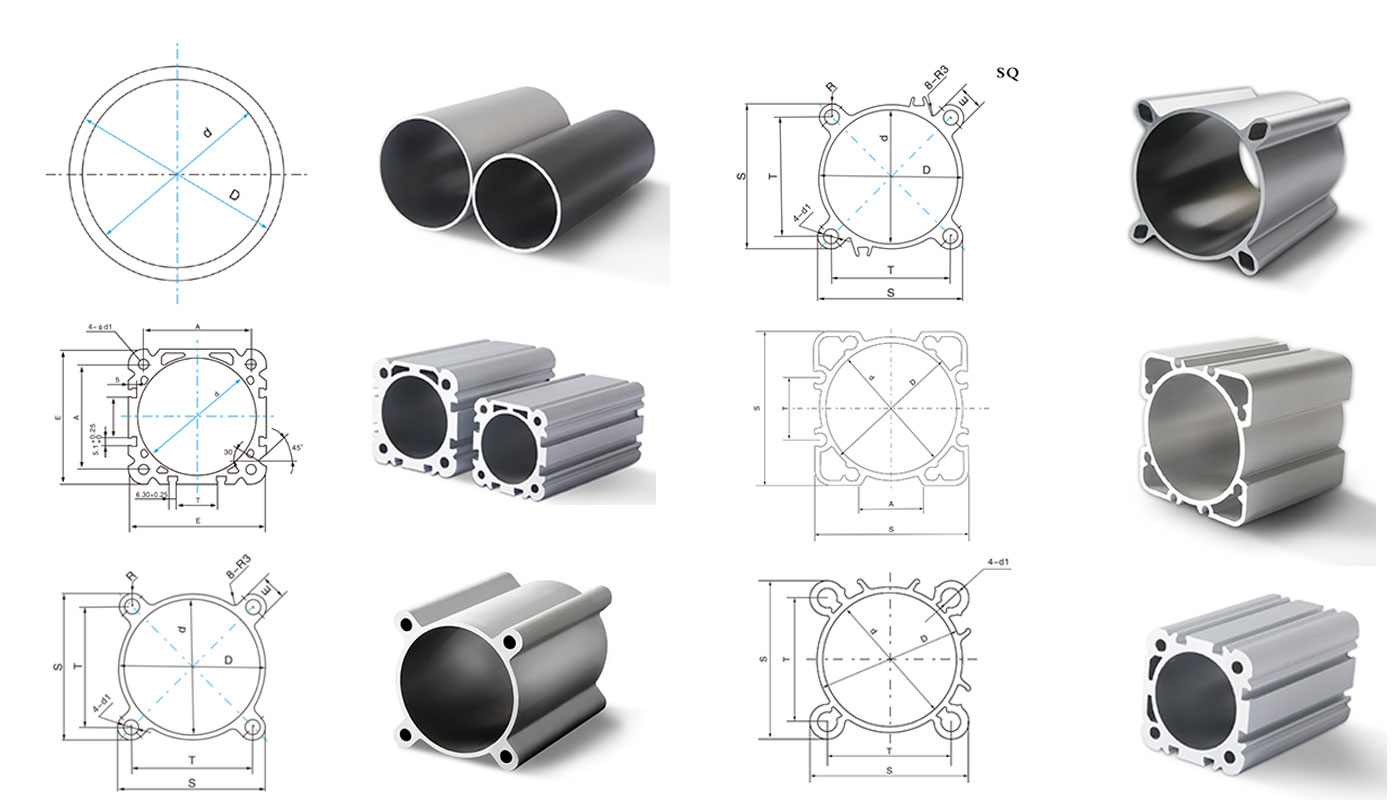

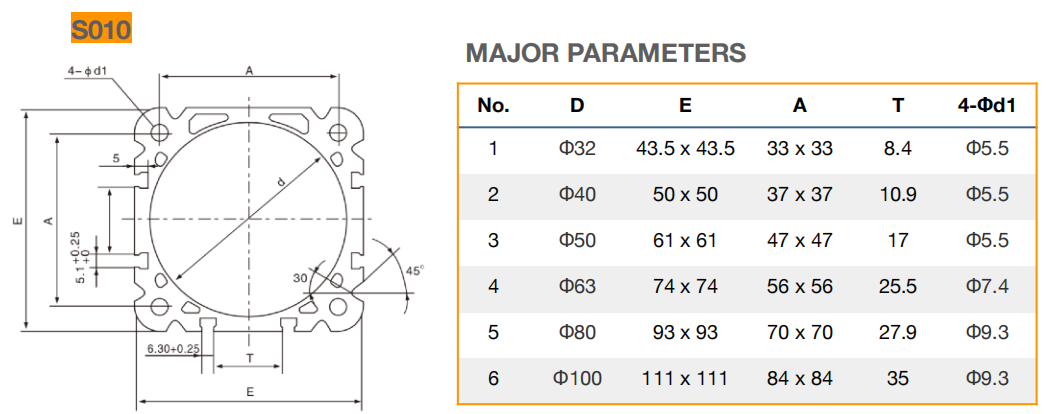

- Technical Parameters

- Tolerance Data

- Advanced Equipment

* Support custom surface finish and your design

| Bore Size | 16/20/25/32/40/50/63/80/100/125/160/200/250/320mm |

| Material | AA6063 T5 |

| Inner Diameter Tolerance | H9-H11 |

| Strightness Tolerance | ≤1mm/1000mm |

| Surface Roughness | Ra <0.6, OR Ra 0.3 upon your request |

| Anodized Film | ≥15 μm |

| Standard Stock Length | 2.0 – 3.0 meters |

| Oxide Film Hardness | ≥ 400HV |

| Tensile strength | 160 Mpa |

| Yield Strength | 110 Mpa |

|

diameter

|

Tolerance | |||||

| H9 | H10 | H11 | ||||

| 16 |

0

|

+0.043 |

0

|

+0.07 |

0

|

+0.110 |

| 20 | +0.052 | +0.084 | +0.130 | |||

| 25 | +0.052 | +0.084 | +0.130 | |||

| 32 | +0.062 | +0.100 | +0.160 | |||

| 40 | +0.062 | +0.100 | +0.160 | |||

| 50 | +0.062 | +0.100 | +0.160 | |||

| 63 | +0.074 | +0.120 | +0.190 | |||

| 70 | +0.074 | +0.120 | +0.190 | |||

| 80 | +0.074 | +0.120 | +0.190 | |||

| 100 | +0.087 | +0.140 | +0.220 | |||

| 125 | +0.100 | +0.160 | +0.250 | |||

| 160 | +0.100 | +0.160 | +0.250 | |||

| 200 | +0.115 | +0.185 | +0.290 | |||

| 250 | +0.115 | +0.185 | +0.290 | |||

| 320 | +0.140 | +0.230 | +0.360 | |||

Yes, Wellste is able to provide honed aluminum cylinder tubing for you to check the quality, Normally stock sample is for free for saving your cost, But it will require tooling cost if custom tube size.

The order amount should more than USD 2000 with existing stock, customize honed aluminum cylinder tubing should no less than 100 meters each type.

It is only taking 7-10 days to complete your sample if the sample size is in stock.

For custom aluminum tubes, commonly it requires 30-35 days at 1st order since it takes more time on making tooling.

30% TT in advance, the balance payment is paid before shipment. OR can be discussed if your qty is large.

Sliver Anodizing, Black Anodizing, Sandy Anodizing, Bronze Hard Anodized.

We inspect the product after each manufacturing process and we have the advanced test facilities and instruments, We also can supply SGS certification for your reference.

Paper tube and exporting wooden case, or customized requirement.

Products You May Looking for

Wellste: Your Leading Honed Aluminum Cylinder Tubing Supplier and Manufacturer in China

As a result, it can be easily transferred from one place to another on the site. Wellste honed aluminum cylinder tubing is very portable.

The lightweight feature of honed aluminum cylinder tubing also means that it is much easier to transport. Wellste honed aluminum cylinder tubing orders have a significantly reduced shipping cost and faster delivery time.

Furthermore, honed aluminum cylinder tubing boasts various characteristics that are quite reliable.

Wellste honed aluminum cylinder tubings present very precise measurements and dimensions. Our experienced workers ensure perfect fitting for your projects.

Wellste honed aluminum cylinder tubing consists of high-strength materials.

Aluminum alloy 6063 plus T5 heat treatment is one reason for the superior strength of honed aluminum cylinder tubing.

Besides, Wellste honed aluminum cylinder tubing has a tensile strength of 160 Mpa and a yield strength of 110 Mpa. Wellste honed aluminum cylinder tubings are the best option for applications that demand superior reliability.

On top of that, Wellste provides various surface finishing techniques you can freely choose. Some of the common surface finishes for honed aluminum cylinder tubing include silver anodized, black anodized, sandy anodized, and hard coat anodized.

Surface finishes will surely improve the visual appearance of your honed aluminum cylinder tubing orders. It will provide an undeniable improvement on your projects’ attractiveness.

At the same time, Wellste honed aluminum cylinder tubing promotes a non-fading color. The dye used stays deep within the aluminum materials’ porous layer.

As a consequence, the color will stay for a long period without the need for frequent repainting.

Yet, the effects of surface finishes are not limited to a more attractive look. It also improves Wellste honed aluminum cylinder tubing’s rust and corrosion resistance.

If you want to have the best possible corrosion and wear resistance, go for hard coat anodized honed aluminum cylinder tubing.

In terms of dimensions, Wellste honed aluminum cylinder tubing has a bore size that ranges from 16-320 millimeters. It has a standard length of 2-3 meters. However, size and length customization is available to fit your projects.

Standard stocks of Wellste honed aluminum cylinder tubing are readily available for shipping. Wellste offers a low MOQ on our aluminum products for you to eliminate extra expenses.

It only takes 7-10 days to prepare the standard sample of your honed aluminum cylinder tubing. On the other hand, a custom design will take a bit longer, between 30 to 35 days.