- 100% confidence to make your design come true

- Engineer timely communication with you anytime 24/7

- No requirement for customized aluminum parts’ order quantity

- Quick and economical delivery arranged by Wellste shipping agent

Custom Made Aluminum Parts

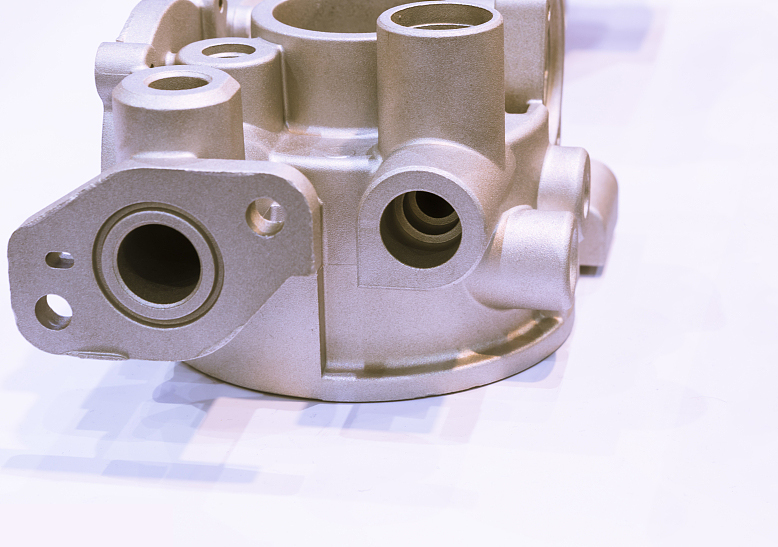

Custom made aluminum parts is a kind of process.

It is different from normal aluminum parts production process. Manufacturers try their best to satisfy customers’ personal or uncommon requirements.

Different people have different requirements. It is related to size, color or production method.

Come to Wellste who offer various production methods, you can always find a suitable solution for your design in mind.

Wellste: The Top Custom Made Aluminum Parts Manufacturer

These methods like aluminum casting, forging, extruding, sheet metal fabrication, and CNC machining services. These methods will definitely satisfy any requirements for custom-made aluminum parts. CNC machining includes milling parts, and laser cutting parts.

Wellste can also offer traditional parts manufacturing services like casting aluminum parts. Wellste runs the business for more than 10 years. Wellste always focuses on custom made aluminum parts. Wellste does well in manufacturing custom machined metal parts and knows a lot about aluminum alloy.

Aluminum alloy is a light weight metal and can undertake high pressure. Wellste will give you satisfactory suggestions based on your actual application. If your project is for aerospace industry application, aluminum 6061 and aluminum 7075 can reach your requirement.

Wellste custom CNC machined parts range from normal hardware to complicated designed components like custom made car parts and so on.

Wellste fully equipped CNC machining lines including 2/4/5-axis machines. Thanks for machines help, Wellste can find suitable solution for your custom aluminum machining project.

Wellste engineering team is confident to handle your project regardless of quantity or design difficulty.

Wellste Specialized as a custom CNC aluminum parts provider, Wellste can offer you tight tolerance and high precision. Wellste tolerance is only 0.01mm!

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Your Premier Custom Made Aluminum Parts Supplier

Furthermore, Wellste cover your any requirements for surface finishing. No matter powder coating or anodizing, Wellste can do it for you under one roof.

Feel free to contact Wellste if you have difficulty designing your product. You will immediately know what unexpected services you can get from Wellste.

Aluminum has been into industry for less than 100 years, but its application range keeps expanding rapidly.

Aluminum has great prospects for development in the human future. It depends on an updated process method and improved aluminum alloy ratios.

One of the most commonly used process methods is CNC custom made aluminum parts.

Pure aluminum is soft because of low-density. It is easy for pure aluminum to get damage. It’s not stable and not applicable in industry.

Aluminum alloy is stronger and harder.Aluminum alloy changes unstable structure.

CNC custom made aluminum parts made from aluminum alloy work actively in different areas including transportation, construsion and aerospace industry.

Different metal ratio causes different alloy properties, following are some commonly used aluminum alloy for your reference. Hope can help you choose the suitable material for your own design project.

6063 is widely applied in aluminum extrusion. The aluminum extrusions are created by the extruded molds.

The shape of the extrusions are various and the surface can stay smooth.

The smooth surface can be anodized perfectly and won’t have any scratches.

So the 6063 comes into the furniture marketing and the construction industry.

6061 has excellent welding characteristics and high toughness.

It is typically used in transportation and printing industry.

It also works well as the metal packaging material for the food and drink.

7075 has the perfect tolerance for heat and is a kind of cold treated forged alloy.

It is far superior to soft steel and works actively in the aerospace industry.

It has the compact structure and high corrosion resistance.

5052 is the most suitable material in metal sheet fabrication and is acceptable in process of bending and milling.

By the way, thanks to its highly corrision resistance ability, it is popular in marine industry. It can create ship propeller and even rocket.

2024 has reasonable composition, good overall performance. Considering its high strength and good fatigue strength, it is commonly utilized as highly loaded parts and components.