- Tolerances decreased to +-0.01mm

- Rapid Global delivery within 15 days

- One-stop CNC drilling solution for you

- Machined prototypes completed in only one day

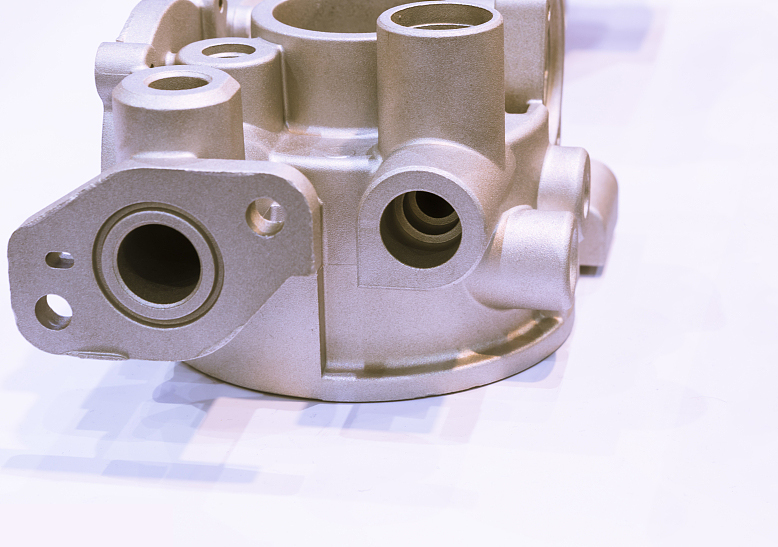

CNC Drilling Parts

CNC drilling parts are created by CNC drilling process. CNC drilling method is one of the most commonly method in CNC machining. It is applied in aerospace, automation and ship fabrication industries.

CNC drilling use a spinning cutting drill bit to create circular holes in fixed workpiece.

Wellste: The Top CNC Drilling Parts Manufacturer

The holes are usually made to assemble screws and bolts for CNC drilling parts’ later application. Nevertheless, CNC drilling parts can be applied for beautiful appearance.Wellste engineers setup diameter and dimension by operating computer. It all depends on your initial purpose of designed components.

Wellste is well-equipped with various kinds of machine tools for CNC drilling parts. We ensure a rapid turnaround time. You can receive your CNC drilling parts even within 10 days and can then start your test immediately.

Wellste has shipping partners and can arrange your delivery quickly and can also save shipping fees for you. With the help of drilling machines, Wellste supports tightly tolerances ranging from 0.01m to even 0.004mm for your CNC drilling parts.

Wellste is confident enough to give you high quality CNC milling services. Specifications all depends on your actual requirement, Wellste is here to realize your design.

Wellste also offer customized surface treatment for CNC drilling parts. If you have any special requirement of color or finish types, feel free to contact us. We do it for you without hesitation and give you a quick quote.

For example, short anodizing, Wellste will do surface treatment for your CNC drilling parts after drilling process. Surface of holes is also included in anodizing treatment then. In order to ensure your product is perfect without any scratches after short anodizing.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Your Premier CNC Drilling Parts Supplier

Wellste is confident to handle any project you have, and Wellste aluminum CNC drilling parts are all certificated by ISO 16090, ISO 14649 and so on. You can come to Wellste engineers and get certificates anytime.

You may not familiar with the term CNC drilling parts, and Wellste is here willing to explain it for you.

How does CNC drilling work during the machining process?

Firstly, Wellste technical engineers deal with design drawings of any format including STEP and DWG and even a sketch. Wellste engineers will make evaluations based on your drawings.

We deal with any format darwing.

Secondly, Wellste engineers have already completed evaluation and are confident enough to prepare CNC drilling parts solution for your own project.

They will choose suitable drill bits and choose appropriate material based on former evaluation. Wellste can solve any problems when designing or een in later testing.

Wellste experience engineers will prepare everything in advance for you.

After these preparations, Wellste engineers are ready to operate your CNC drilling parts.

They will control computer panel and start CNC drilling immediately. CNC spindle comes down to deal with workpiece and bits will drill holes with setup size and diameter.

Wellste offers CNC drilling services for production of prototypes or bulk production regardless of design complexity.

Wellste apply different types of drill methods including upright, bench and radial.

These methods allow Wellste to drill holes based on your requirement.

No matter simple or difficult, Wellste can even create patterns as far as 8 cm in dimension.

Wellste CNC drilling parts have high accuracy in precise tolerances.

It saves cost for you while increasing productive efficiency.

Wellste CNC drilling parts will benefit your total product marketing lines.