- Cost-Effective Solutions

- High durability and Low-maintenance

- ISO9001-2001 and ISO 9001-2008 Authenticated Company

- 100% Reliable Aluminium Extrusion Manufacturer and Supplier

Aluminum Picture Frame Extrusions

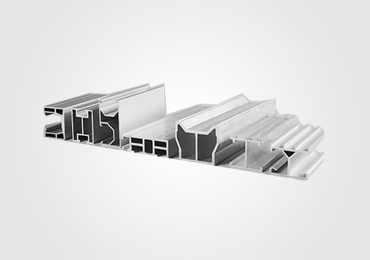

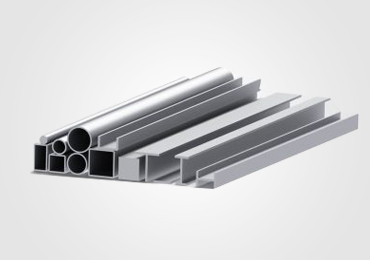

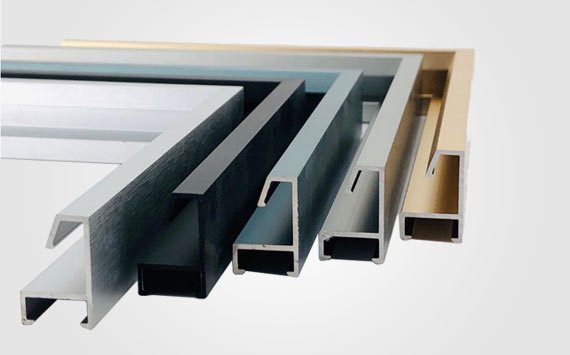

Wellste aluminum picture frame extrusions are broadly used due to its easy machining, flexibility assembling, good corrosion resistance, durability, and non-magnetic properties.

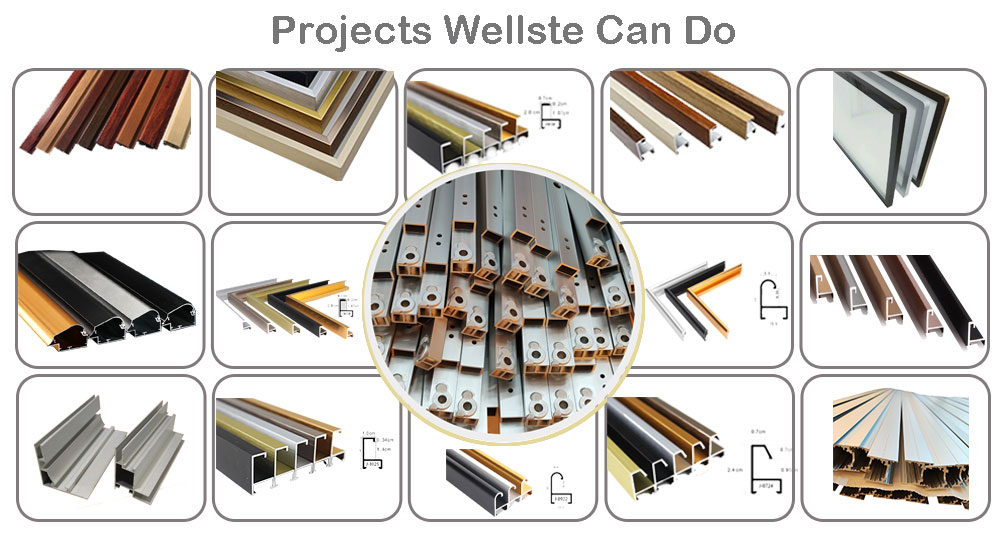

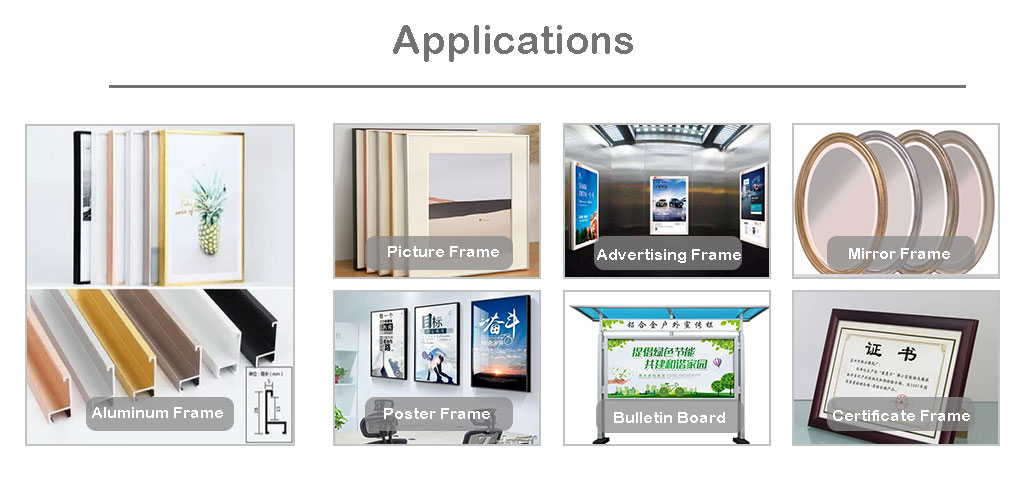

These are utilized in many applications such as in photo frame, conveyor roller, sliding window, curtain wall profile, 3D printer, framing table, T Slot framing system, and many more.

Your Premier Aluminum Picture Frame Extrusions Manufacturer

Wellste aluminum picture frame extrusions are lightweight, durable, and easy to install. Wellste aluminum picture frame extrusions can cover a diversity of industries that you can imagine.

Wellste Aluminum manufacture and supply aluminum picture frame extrusions for more than 20 years. We offer high quality and widest range for your Aluminum profile system or Modular aluminum framing.

The most common aluminum alloy number for producing aluminum picture frame extrusions is 6063. 6063 Aluminum Alloy is widely used as building aluminum windows and doors, a frame of curtain wall, and general accessories of industrial products. It will look appealing after anodizing or coating surface.

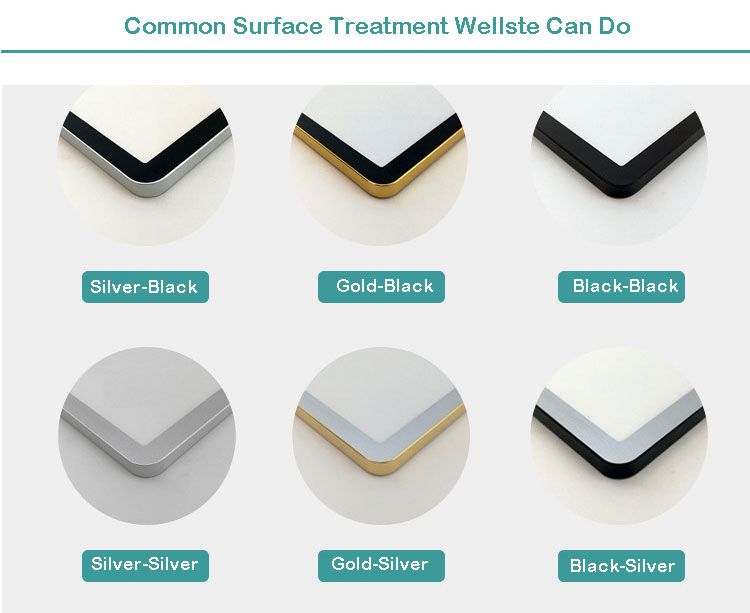

They also come in a clear anodized or sandblasting or stain anodized decorative finish, which makes the aluminum picture frame extrusions more resistant to corrosion. And you can choose the color you prefer for your aluminum picture frame extrusions like silver, black, blue, wood color, RAL powder coating color, and so on.

| Item Type | Aluminum Picture Frame Extrusions |

| Material | Aluminum Alloy 6063/6061/6463/6000 Series |

| Temper | T4/T5/T6 |

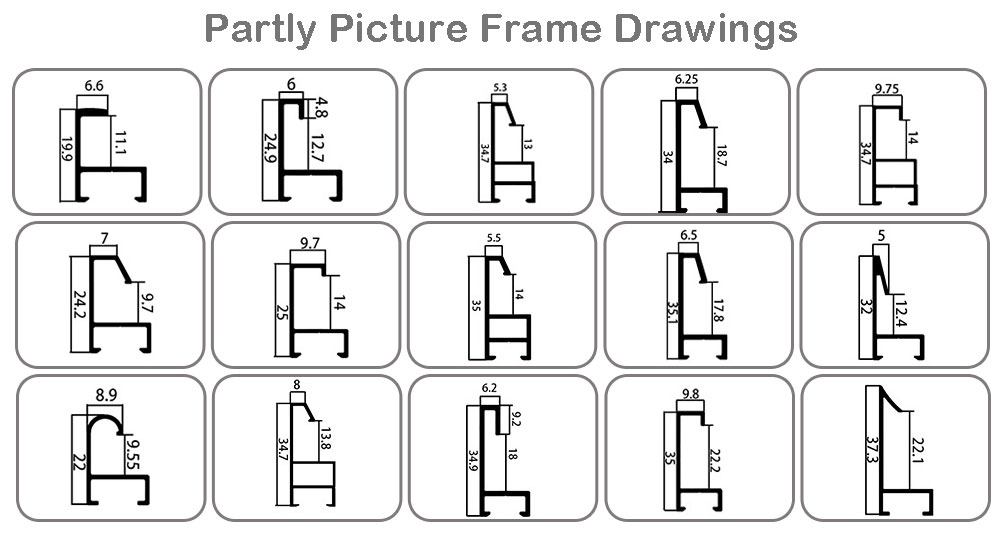

| Shapes | Strip, and customized |

| Application | Picture frame, advertising display in a shopping mall, Metro, Airport, mobile shop and so on. |

| Type | Single side display, double sides display; Floor standing, Wall-mounted |

| Surface treatment | Anodizing, Mill finish, Electroplating, Polishing, Sand blasted, Powder coating, Silver plating, Brushed, Painted, PVDF etc. |

| Deep processing | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| Standard | GB, ASTM , AISI , DIN , BS, JIS |

| Certification | ISO9001 |

| Delivery Time | 15-20 days after sample confirmed & down payment, or negotiated |

| OEM/ODM | Acceptable |

| Service | 1. Free sample, Free design; 2. OEM/ODM available; 3. Custom-made request; 4. New design solution suggestion |

Wellste also offers different surface treatment, which is colorful and Polishing Shiny anodizing, electrophoresis coating, powder coating, and PVDF coating. Plus, Wellste has an innovative anodized line imported from Germany, which can exceed your various demand with high-level quality.

Trust Wellste! We have highly professional engineers that will help you purchase the most suitable aluminum extrusion products.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Wellste: Your Perfect Aluminum Picture Frame Extrusions Supplier

Are you looking for the best manufacturer of aluminum picture frame extrusions? Why not settle with Wellste?

Wellste Aluminum is a well-established manufacturer for aluminum products with more than 20 years of expertise. We’re confident in giving our customers complete satisfaction.

We can produce aluminum picture frame extrusions in 6061,6063, 3003, 6463 aluminum alloy series. You can contact and consult our sales engineer for your special alloy number requirements in 1000 series,2000 series, 3000 series, 5000 series, 6000 series, and 7000 series of your aluminum picture frame extrusions. We can extrude it for you!

Wellste aluminum picture frame extrusions are offered in plenty of stock for standard size and matched accessories. You can customize your own design with our latest Tooling Technology.

Our products have been exported to many countries due to its reliability and high-performance such as in America, Europe, Africa, Poland, and many more. Wellste aluminum picture frame extrusions earned the trust and respect of many valued customers. All clients are always welcome to visit and discuss business with us.

In China, Wellste is one of the popular manufacturers and suppliers of high-quality aluminum products that comes from high-grade materials. We obtained SGS, CE, ISO certifications. In short, Wellste is an expert when it comes to your aluminum extrusion products and accessories need.

Our company has advanced double traction extrusion equipment, vertical processing center, high precision CNC milling machine, 10 meters long profile processing center, saw, double head saw, puncher, bending machine, tapping machine, drilling machine, and other mechanical equipment. It can guarantee fast production and delivery time for your orders.

All your aluminum extrusion necessities are found in Wellste! Don’t hesitate to count on Wellste, your one-stop-shop solution.

Whether you`re a distributor, supplier, or custom factory, Wellste can satisfy your requirements.

We provide 24/7 customer service. We will be on hand to answer any questions you have at any stage of the project. Email us now!

Aluminum Picture Frame Extrusions: The Ultimate FAQ Guide

Let’s look at some fundamental aspects you should consider when choosing aluminum picture frame extrusions.

Take a look:

What Are Aluminum Picture Frame Extrusions?

An Aluminum Picture Frame Extrusion

Aluminum picture frame extrusions are extruded picture frames for your photos, canvases, or panes.

The structure is straightforward and comprises a few unique parts, screws, and a prominent upper bone.

Aluminum picture frame extrusions are suitable for outdoor and indoor applications as they have very high wind resistance.

They will provide you with a broad conception space that will enable you to create even more beautiful and unique works.

What Are Aluminum Tolerances Available For Picture Frame Extrusions?

Tolerances refer to unavoidable distortions that occur to the aluminum metal during the extrusion process.

It applies to such dimensions as flatness, straightness, or twist.

These standards are important because they contribute to maintaining reliability and consistency in the extrusion dimensions of the aluminum picture frame extrusions.

For this case, the achievable tolerances are:

- Width(+/- 3mm) and length(+/- 3mm)

- The general straightness for standard tolerance should be 0.0125 inches per foot.

How Much Do Aluminum Picture Frame Extrusions Cost?

The prices of aluminum picture frame extrusions range between USD 4-200 depending on the size, type of finish, and weight.

The typical minimum order quantity is usually half a ton, which is valued/priced at four dollars per five hundred kilograms.

The aluminum picture frame extrusions are worth every dime as they boast a superior quality build and finish.

If you have any specific price conditions, or you’d like to have deeper understanding of how we calculate the final extrusion cost, please let us know.

We’ll be happy to talk you through any questions.

The Cost Of An Aluminum Picture Frame Depends On Size , Type Of Finish or Weight

How Do You Manufacture Aluminum Picture Frame Extrusions?

Simple, the manufacturing process involves pushing heated aluminum alloys through a cavity known as a die.

This process produces parts that have distinct cross-sectional profiles as the shape in the die cavity.

The result is often an eight- to a twenty-four-foot-long profile later fabricated, finished, and heat-treated to meet your specifications.

A more detailed description of the process is below:-

- Preparation of extrusion die. The die cavity has to have a similar shape and size to the desired cross-sectional profile of the finished product. The die is then put into an extrusion press.

- A billet of desired aluminum alloy is heated to a very high temperature until its malleable. It is heated at 500 °C.

- The aluminum alloy billet is then moved to the extrusion press. Afterwards, it is pushed into a container.

- The intense pressure, i.e., 15000 tons, forces the malleable alloy billet through the die cavity. It is then cut to the table length and then cooled.

- The final step of the process is finishing and cutting to length.

Which Aluminum Alloys Do You Use For The Picture Frame Extrusions?

We use only the best alloys to make our picture frame extrusions. These include 6005, 6063, and 6463.

- Alloy 6463. This is the most common aluminum alloy used in extrusion. When heated, its ductility reduces, and it becomes even more robust.

They are best for custom profiles such as aluminum picture frame extrusions.

They are composed of minimal amounts of zinc and copper and are ninety-eight percent pure aluminum.

This means they are highly dense, tensile, and robust.

Aluminum Picture frame Extrusions Made From Alloy 6463

- Alloy 6063. This aluminum alloy provides the neatest finish of all extrudable aluminum alloys.

It is highly corrosion resistant and can produce very lustrous finishes from the hard coating, dipping, etc.

Alloy 6063 Is Also Used In Making Picture Frames

- Alloy 6005. If you intend to use your picture frame extrusion for applications that require durability and strength, then this is the best option.

Its silicon composition significantly reduces its melting point, thus making it easy to extrude.

Advertising Picture Frames Made From Alloy 6005

What Certifications Do Aluminum Picture Frame Extrusions Have?

The standard certifications which our aluminum picture frame extrusions conform to include the following:-

- EN 12392:2016 EU/68/2014. These are standards that describe requisite conditions that should be met by aluminum alloys used in applications that may involve high pressure.

- EN 12020-2. This is perhaps the most essential standard as it describes the requisite conditions for alloys to be used for complex shapes.

Such alloys include 6060, 6005, 6005 A, etc.

Generally, they are standards to be met by aluminum products with low tolerances like aluminum picture frame extrusions.

- They also conform to standards posited by DIN, ASTMB221, and EN755

Can You Supply Sample Aluminum Picture Frame Extrusions Before The Bulk Run?

Yes, we can provide samples for these aluminum picture frame extrusions.

However, the additional costs like freight charges will be your responsibility.

An alternative way of handling such situations would be to order a 3d print of your desired aluminum picture frame extrusion design.

This is more cost friendly than ordering an actual extrusion sample.

What Are The Advantages Of Using Aluminum Picture Frame Extrusions Over Other Materials?

- Aluminum picture frame extrusions, also known as photo frames, poster frames, or advertising frames, have an elegant look.

They have thick three-dimensional effects, brushed/metal textures that make them appear so.

They are available in various colors to meet your different application needs, including titanium gold, silver, sub-black, etc.

- Aluminum picture frame extrusions have splendid low and high-temperature performance in contrast to other materials.

Moreover, they are easy to install, do not rust, are very robust, do not deform, and are versatile.

- Aluminum picture extrusions are solid and have high levels of sturdiness. Meaning they can hold up heavy window panes.

- With aluminum picture frame extrusions, there are dozens of styles to choose from. There are six mainstream color options to choose from, i.e., porcelain gold, black, purple gold, titanium gold, bright silver, and sub silver.

There are also many surface treatment options, i.e., electroplating, polishing, electrophoresis, wire drawing, etc.

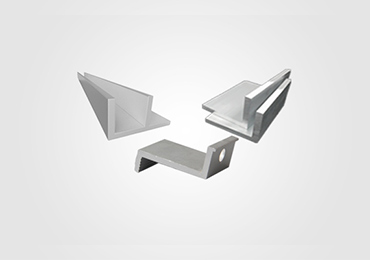

- In addition, the aluminum picture frame extrusions are customizable into different sizes and shapes, depending on your preferences.

You can choose to have an extrusion of a different size or design.

For example, if your application requires frequent frame changes, you can customize your extrusion to be a wide frame open type.

This will go a long way to ensure the longevity of your extrusion.

The Aluminum Picture Frame Extrusions Come In Various Shapes And Designs

Can You Recycle Aluminum Picture Frame Extrusions?

Yes. Aluminum picture frame extrusions are very environmentally sustainable in contrast to other materials.

This is because they are made from Aluminium material, which is a very easy material to recycle.

You can recycle aluminum picture frame extrusions without compromising their quality.

To customize, choose a sizing kit for both width and length after measuring the overall width and height from the outer edges of the extrusion.

Then proceed to use the included hardware to assemble the frame.

What Are The Limitations Of Using Aluminum Picture Frame Extrusions?

- Aluminum picture frame extrusions can get easily damaged or scratched due to carelessness or misuse.

- Aluminum picture frame extrusions may require custom components, e.g., bends. These custom parts may be costly and will, in turn, lead to you incurring a bending charge from the suppliers or manufacturers.

- Some parts of the aluminum picture frame extrusions are very complex. This makes them vulnerable as they can break very easily.

Can You Customize Aluminum Picture Frame Extrusions?

Of course, we can customize aluminum picture frame extrusions to produce frames in sizes you prefer from stock with a slim profile.

You can also achieve different finishes types, including glossy black, brite gold, brite aluminum, etc.

What Variety Of Finishes Are Available For Aluminum Picture Frame Extrusions?

Adding finishing to the aluminum picture frame extrusions presents the following advantages:-

- It enhances the appearance.

- Prepares the surface for additional customizations like painting

- Protects the metal from environmental conditions that may cause damages like corrosion.

The variety of finishes include:-

- Mechanical finishing is used to add a texture to the surface of the aluminum picture frame extrusions. This type of finishing enhances the surface quality and can be done through techniques like sanding, polishing, blasting, buffing, etc.

- Pretreatment finishing. This involves applying a coat of pretreatment solution on the aluminum picture frame extrusion surface after cleaning it with an acidic or alkaline solution.

- Chemical finishes – The aluminum picture frame extrusions are dipped into chemical solutions using techniques such as bright dipping. The preferred solutions are often phosphoric or nitric acid. This type of chemical finishing produces a mirror effect on the extrusion.

- Anodizing finishes – In this type, an electrical process and a chemical are combined. This type provides the aluminum picture frame extrusions with exceptional corrosion resistance, making the oxide film thicker. This type of finish also allows vibrant surface colors.

- Powder coating finishes – To boost the rigidity of the film, the best way would be to add a powder coating finish.

Anodized Aluminum Extrusion picture Frame

What Pretreatment Solutions Do You Provide For Aluminum Picture Frame Extrusions?

These involve applying a coat of pretreatment solutions on the extrusion surface after cleaning it with an acidic or alkaline solution.

There are two types of pretreatment techniques, namely, chrome-free and chrome converter coatings.

- Chrome-free pretreatment coatings do not have any hexavalent chromium composition. These pretreatment method has been proven to meet requisite industry standards to be considered adequate.

- Chrome converter pretreatment coatings convert the aluminum picture frame extrusion surface into an inert state. Unlike the chrome-free pretreatment coatings, these have hexavalent chromium.

What Is The Lifespan Of Aluminum Picture Frame Extrusions?

You should expect a lifespan of up to forty years for the aluminum picture frame extrusions.

They are made from the most long-lasting and durable material available for picture frames, i.e., Aluminum.

Furthermore, the aluminum picture frame extrusion is protected against harsh environmental conditions that may cause damages such as corrosion.

This is done by powder coating.

They also require very minimal maintenance.

Are Aluminum Picture Frame Extrusions Lead-Free?

This depends on the type of alloy used to extrude the aluminum picture frame.

It is most commonly present in alloys like 2011, 6262, and 6061, but only in small amounts.

We do not use said alloys in our extrusion process. You should not have any reason to worry.

Where Can You Use Aluminum Picture Frame Extrusions?

You can use the aluminum picture frame extrusions for home decoration both outdoors and indoors. You can use them to contain pictures, photos, art, canvases, or panes.

How Do You Assemble Aluminum Picture Frame Extrusions?

The first step is to start with one section of the top and the side of the frame.

With corner in hand, proceed to insert the backing angle, lettering side up with the front angle.

Then, clamp the corner securely with your fingers while tightening with a screwdriver. Proceed to repeat the above steps on the other side of the frame.

Slide your artwork, photo, canvas, acrylic, or pane into the frame channel, and you’re ready to attach the last section.

Add your hanging hardware.

Measure approximately 1/3 of the frame’s height down from the top to know where to position. Insert and tighten.

What Is The Typical Lead Time For Aluminum Picture Frame Extrusions Orders?

The lead time for our aluminum picture frame extrusions typically lasts between a fortnight and three weeks.

This period covers the entire process from extrusion to cutting, to packaging, and finally, to shipping.

For most situations, however, the lead time is usually two to three fortnights.

What Is The Minimum MOQ For Aluminum Picture Frame Extrusions?

Our minimum order quantity is relatively low and flexible.

It typically ranges between 500kg to 1 ton, depending on the size of the aluminum picture frame extrusions.

Accommodation of smaller runs inherently results in you incurring extra costs from die charges, freight, and packaging charges.

We do not hold inventory for orders that we consider small since we only do our aluminum picture frame extrusions on order.

Before you choose to go on a bulk run, please order a sample first, especially if you are a small scale buyer and find the MOQ expensive.

Only order once you are satisfied or pleased with what you’re getting.

How Do You Check Quality Of Aluminum Picture Frame Extrusions?

- You can check the quality of the aluminum picture extrusions by verifying their certifications against standards they claim to conform to.

These certifications usually come with your order or are marked on the extrusions.

They are strategically placed to make it easy for you to find.

- Another way to check the quality of your aluminum picture frame extrusions is to test their tolerance.

We recommend the following general guidelines in the testing process:-

- Angularity should vary depending upon the wall thickness and surface size of the extrusion. Thus, the available variation should be between ±2 degrees and ±1 degrees.

- The general straightness for standard tolerance should be 0.0125 inches per foot.

- The general standard tolerance for twists should be ½ °/ft.

- The wall thickness standard tolerance should be ±10 percent for each specified dimension.

What Are The Available Color Options For Aluminum Picture Frame Extrusion?

Aluminum picture frame extrusions are available in various colors, including silver, white, bronze, gold, etc. We anodize all our aluminum picture frame extrusions.

The anodization process often produces colored aluminum oxide layers on the aluminum picture frame extrusion surface.

This, in turn, leads to the production of different shades of bronze, including clear, black, and gold.

We can also produce custom colors to match your needs or preferences.

Colours Are Customized To Suit Your Preference or Needs

At Wellste, we design and manufacture a range of aluminum picture frame extrusions.

It all depends on your unique requirements and specifications – contact us now.