- Quick quotation after your inquiry within 24 hours

- Support prototype production and have NO MOQ for you

- Extremely strict QC system before and during production

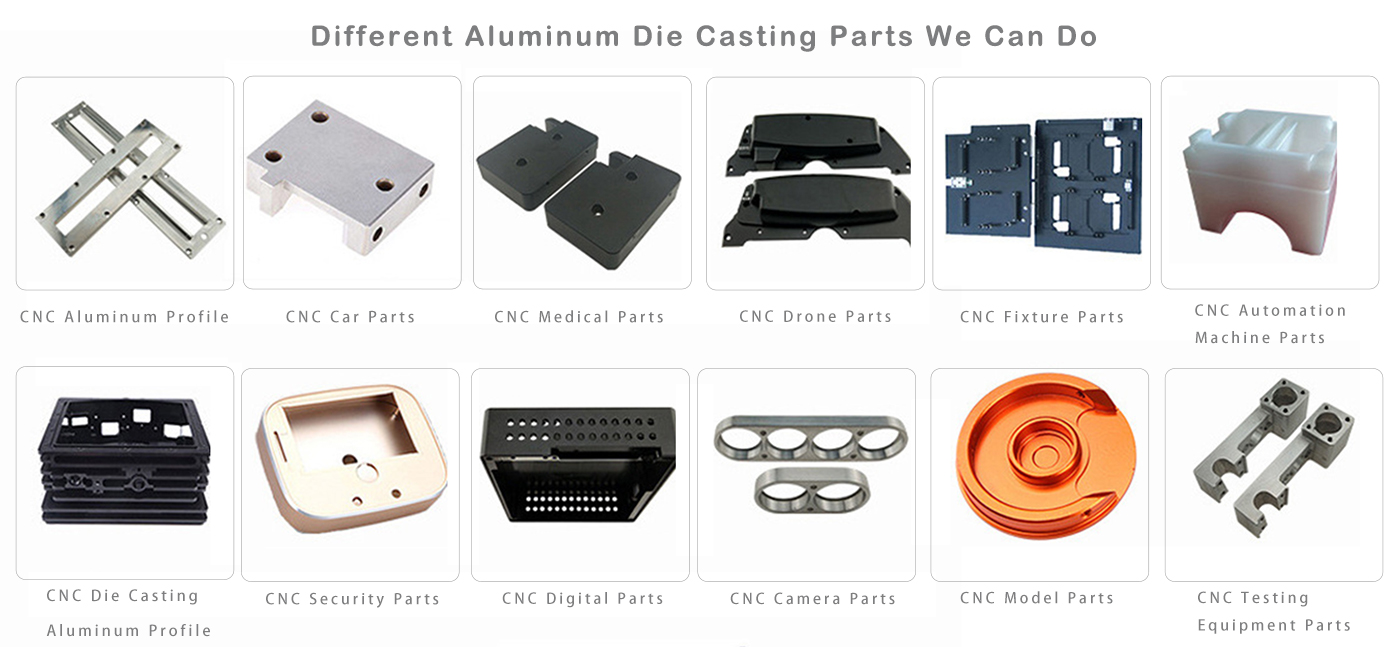

- A wide range of CNC machining methods for your reference

Aluminum Die Casting Parts

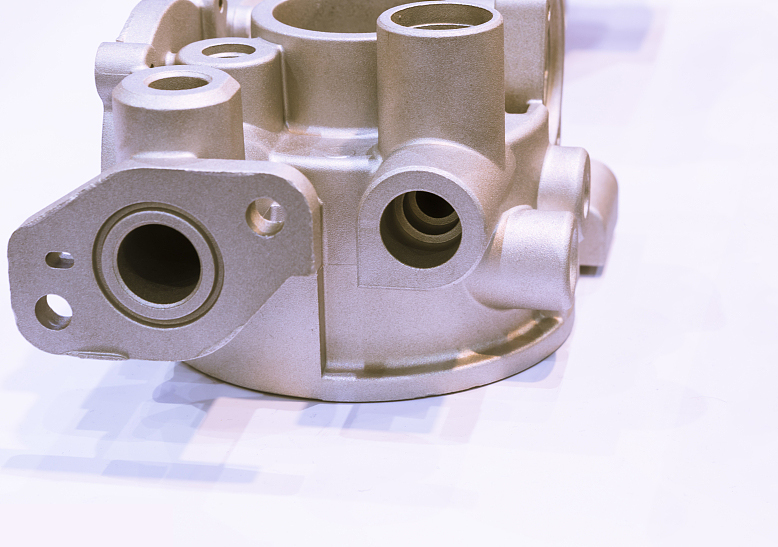

Aluminum die casting parts go through die casting process. Die casting process pours aluminum alloy into a sealed die casting machine. Wellste workers heat aluminum alloy until it becomes tender. Aluminum alloy runs as water into steel cast mold under high pressure.

After cooling down, aluminum alloy is harder and stronger. Opening mold clamps, we can then get a aluminum die casting parts as required. Aluminum die casting is suggested for your project related to aluminum alloys.

Wellste: The Top Aluminum Die Casting Parts Manufacturer

Wellste supports rapid prototype service for you if your lead time is very tight. Wellste started die casting business more than 10 years.

We have our own technical engineering team. Every member of the engineering team is ready to help you improve design 24/7.

What counts most in manufacturing business? It’s high-standard equipment. Wellste keeps expanding its factory and die casting machine lines in order to offer better service.

We have technology like an investment casting process for you.

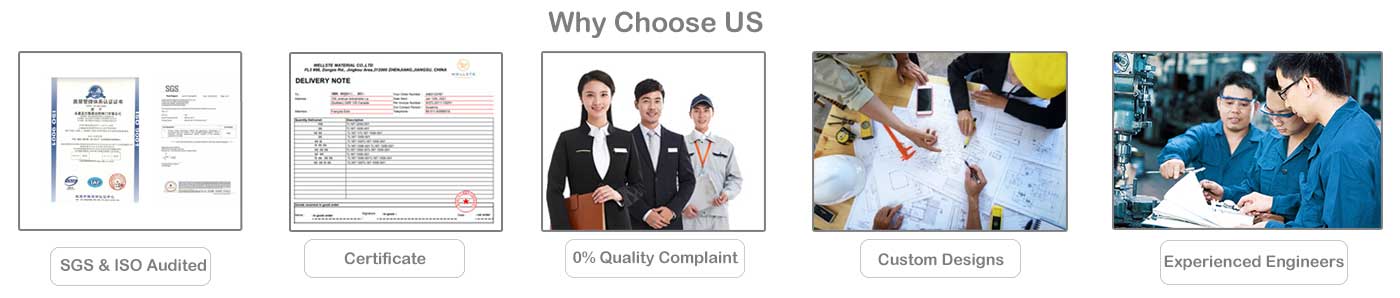

We aim at building a hundred-year business with Wellste excellent product quality. Wellste QC system ensures every stage in die casting is excellent. Final aluminum die casting parts can absolutely reach your original requirements without any mistake about specification.

There are two traditional types of die cast options for your project, one is hot chamber die casting, and another is cold chamber die casting. Hot chamber die casting aluminum alloys is a very quick process. It can finish total production in only 15 minutes. Quick turnaround time is important for prototyping.

Cold chamber die casting process can only deal with aluminum alloy. It is not easy to melt when heating. This method supports bigger size production. Furthermore, it can handle product with thinner wall easily. Thanks to high pressure, aluminum alloys becomes stronger and more durable.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Your Premier Aluminum Die Casting Parts Supplier

Wellste has separated furnace to molten metal like aluminum alloy in advance. And Wellste workers pour melt aluminum alloy quickly into mold.

Wellste suggested this method for your aluminum die casting parts project. It doesn’t need to heat mold itself and saves a lot of fixing fees. It is a very economical option if you only need a small batch before bulk production.

Wellste has wide variety cast aluminum parts.

Aluminum die cast is suitable for your small batch production in the developing stage. Aluminum alloy has good corrosion resistance. It has good mechanical properties like flexibility, electrical conductivity as well.

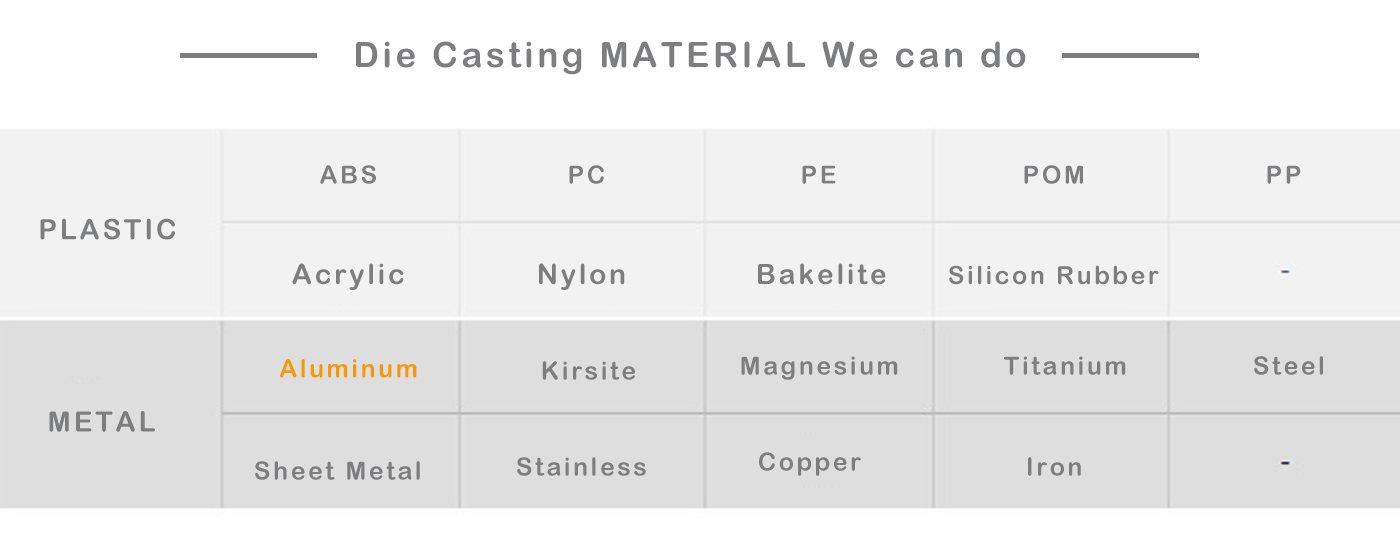

Material counts most at the very beginning of designing casting aluminum parts.. Most commonly used die casting alloys of aluminum are ADC10,ADC12, A380 and so one. We are here to help you make a suitable choice.

Wellste experienced engineering team will keep in touch with you until you confirm aluminum die casting parts design details. Wellste die casting services will start from your inquiry to after-sales services.

Wellste purpose is to reach any requirement you have and ensure the high quality of Wellste aluminum die casting parts. What’s more, considering Wellste high production capacity, we offer you the most economical production plan compared to other suppliers.

Wellste strict QC system makes manufacturing process totally clear to you. You can get photos and videos from Wellste any time during production.

We also have extra secondary operations for your project, we can do CNC machining or surface treatment for you. We have many surface finish options for your die cast components. After aluminum die casting process, we can do powdered coating or anodizing for your aluminum die cast products.

Wellste is an ISO 9001 certificated company, we have ISO 8062 certificates and so on. You can get these certificates directly from Wellste technical engineers.

We are full of confidence to produce your aluminum die casting parts perfectly and reach any standards your industry may have. We also has an assembling service for your project.

If you need us to assemble different parts together in advance, Wellste assembling lines stand by to service you.

Wellste rooted in aluminum die casting for decades of years and has Wellste own shipping agent around the world. We prepare speedy delivery at a low cost for you with the help of Wellste shipping partners.

Wellste technical engineers are all rich in aluminum die casting parts manufacturing experience. They are actively facing any challenges. We will never let you down and overcome any difficulties in your project.

Wellste supports your every project regardless of order quantity. We are willing to produce only one prototype and are also able to handle high volume aluminum die casting parts. All casting produced aluminum parts will be handled carefully. Wellste keeps improving aluminum die casting services.