- CNC machining advanced technology service

- Wide range of different series aluminum alloys for you

- Anodizing and powder-coating surface treatment available

- Experienced engineers 24/7 in time reaction to your question

Aluminum CNC Turning Parts

Aluminum CNC turning parts are created by aluminum CNC turning method. Aluminum CNC turning is a type of aluminum CNC machining.

Wellste engineers will fix a whole aluminum alloy workpiece on CNC turning lathe. After high-speed operation, cutting blades on lathe will remove material away from original workpiece.

Wellste CNC aluminum machining including CNC turning, CNC milling and drilling.

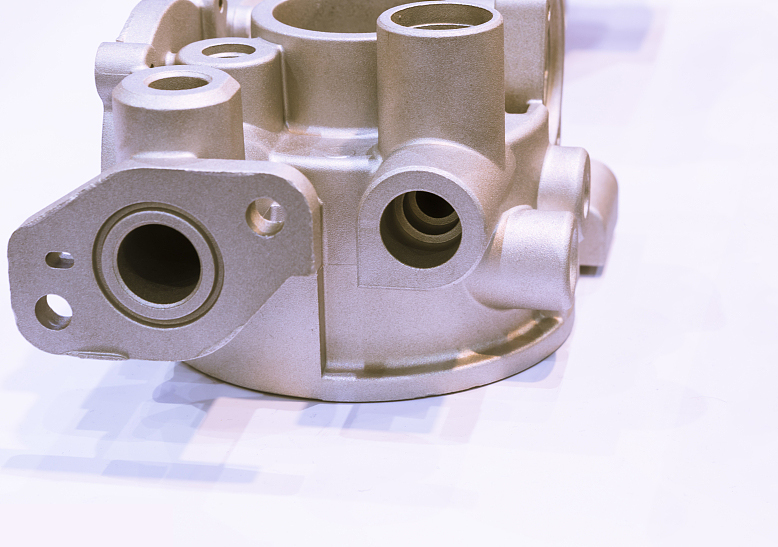

Wellste: The Top Aluminum Die Casting Parts Manufacturer

Wellste both manufactures and provide various custom machined aluminum parts. Wellste has advanced equipment and technology.

They enable Wellste to CNC machine highly precised aluminum parts with or without surface finish.

Wellste machining services all depend on customers’ personal requirements. Wellste aluminum CNC turning parts are known for high quality. They works actively in a variety of industry applications.

We suggest that you can choose the most suitable aluminum alloy for your own aluminum CNC turning parts project. Machinability aluminum alloy will always be the best options for your project!

Wellste engineers has been in aluminum CNC machining area for more than 10 years. They deal with various aluminum CNC turning parts created by different aluminum alloy everyday.

Don’t worry and they can obviously solve any problem you have.

Wellste engineers will prepare cutting tools for you. In order to get ready for production. CNC machines can produce aluminum components as you require automatically.

Contact Wellste experienced engineers anytime if you have any difficulties choosing a right CNC machining method. Aluminium is a kind of metal with low-weight,high weight ratio, high strength.

Pure aluminium is tender and easy to oxidize. But, after combining with other metal elements, aluminum becomes aluminum alloy.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Your Premier Aluminum CNC Turning Parts Supplier

Aluminum alloy is stronger and harder.Aluminum has unique physical capacity and can form nearly any shape. It is good for producing machined parts. Allum alloys can be fixed in the middle of CNC lathes for further operation.

Aluminum alloy can create thick plate to service Military defense system. It can also become as thin as a paper and work as food package.

Aluminum CNC Turning parts are commonly used for different industrial fields. Aluminium CNC turning is really a economical method and can also ensure excellent quality.

Some of commonly utilized aluminum alloys are shown below for your reference.

Hope it is helpful for you when making material choice for your aluminum CNC turning parts project.

Alloy aluminum 6061 can work well under operations of 4 or 5-axis CNC machines. Its perfect physical properties and flexibility ensure that it can be welded easily when producing aluminum CNC turning parts.

Wellste is able to adjust 6061 hardness. It depends on your specific requirements. We offer surface treatment including normal anodizing, hard anodizing and powder-coating for aluminum CNC turning parts.

If you want to create a product with arch of different radius, 6061 is a good choice. It is because 6061 bends easily during the CNC machining operation.

Alloy 7075 can undertake high-load pressure. But it can’t bend as easy as 6061 because of its hardness. Also, this alloy has good ability to resist corrosion. It has good fatigue strength and good machinability, but not weldable.

Thanks to its low-weigh and high-hardness, 7075 is welcomed in aerospace and marine industry. 7075 aluminum CNC turning parts usually work as ship components under seawater or wings for airplane framework.

Alloy 2024 works actively everywhere among army, airplane and transportation areas. This alloy is easy to bend and can undertake corrosion under awful working circumstance. Unfortunately, it is also a kind of material without good flexibility.

Anodizing and coating methods or wrapping aluminum CNC turning parts with extra aluminum layers can also improve corrosion resistance.

2024 aluminum CNC turning parts usually work as high-load parts, structures. They exclude stamping forging parts. For example, aircraft frame parts, ribs and rivets.

As you can see from introductions to aluminum alloys application, they distinguish from each other.