- 100% pure A00 Aluminum Ingot

- Owns high-technology 35 extrusion lines

- Manufacture based on your designs and specifications

- More than 2 decades of aluminum industry experience

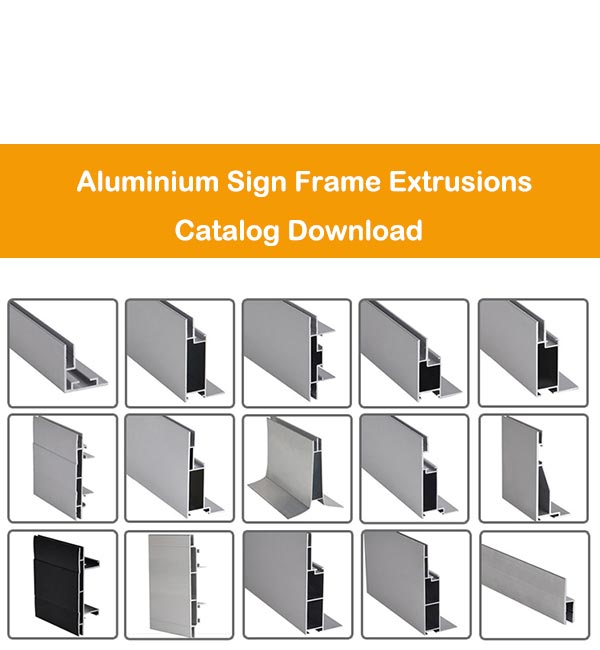

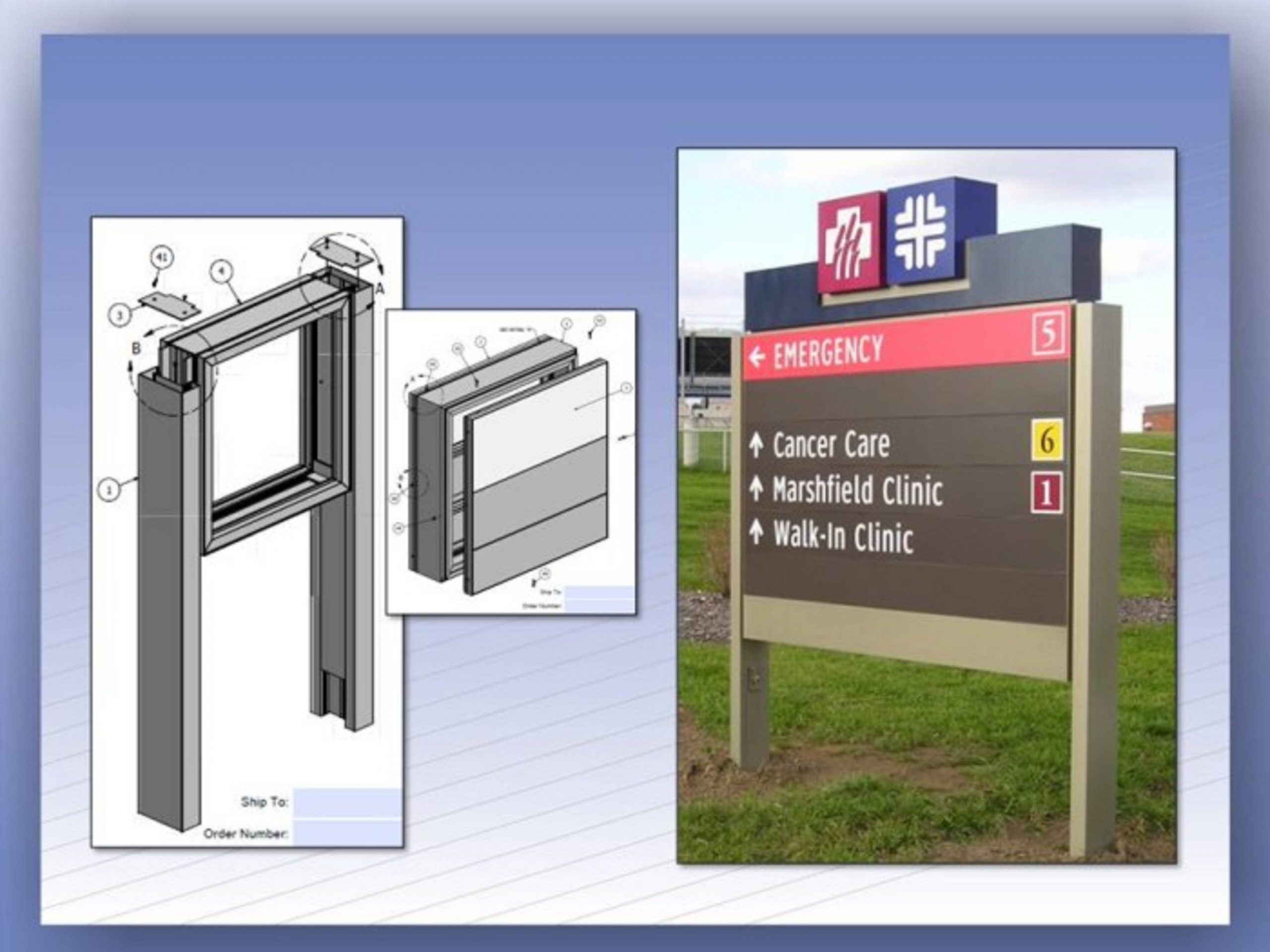

Aluminium Sign Frame Extrusions

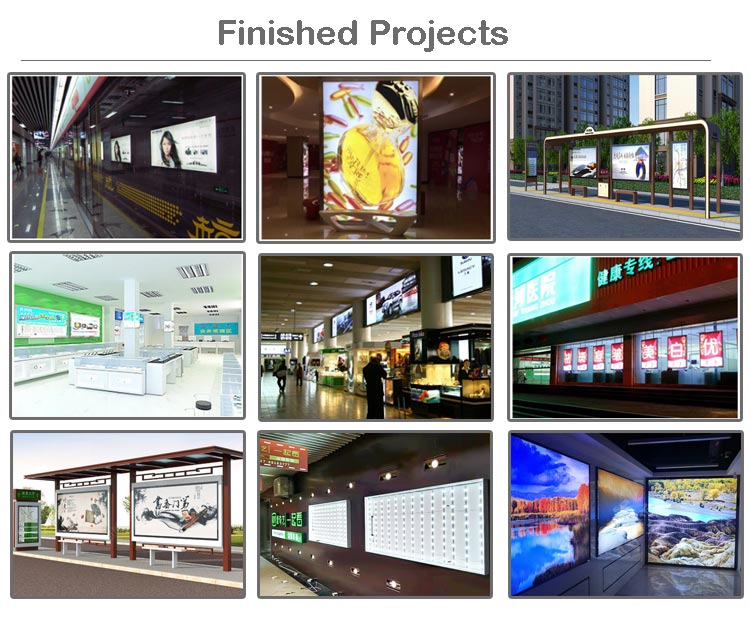

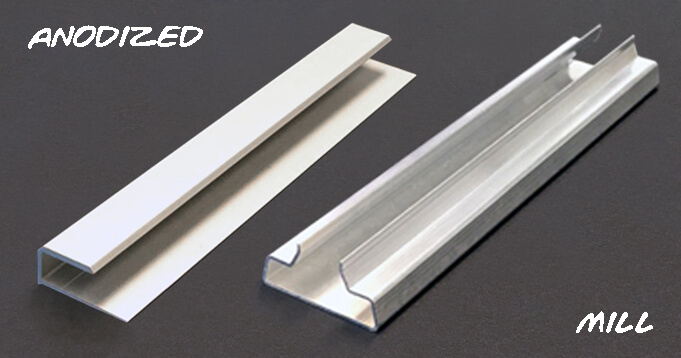

Wellste supplies aluminum sign frame extrusions all over the country. We stock them in standard anodized finish, satin, or clear mill finish based on your request. 100% satisfying services, great pricing, and personalized customer service are all you can encounter from us.

Wellste: The Top Aluminium Sign Frame Extrusions Manufacturer

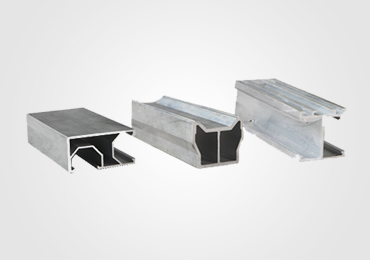

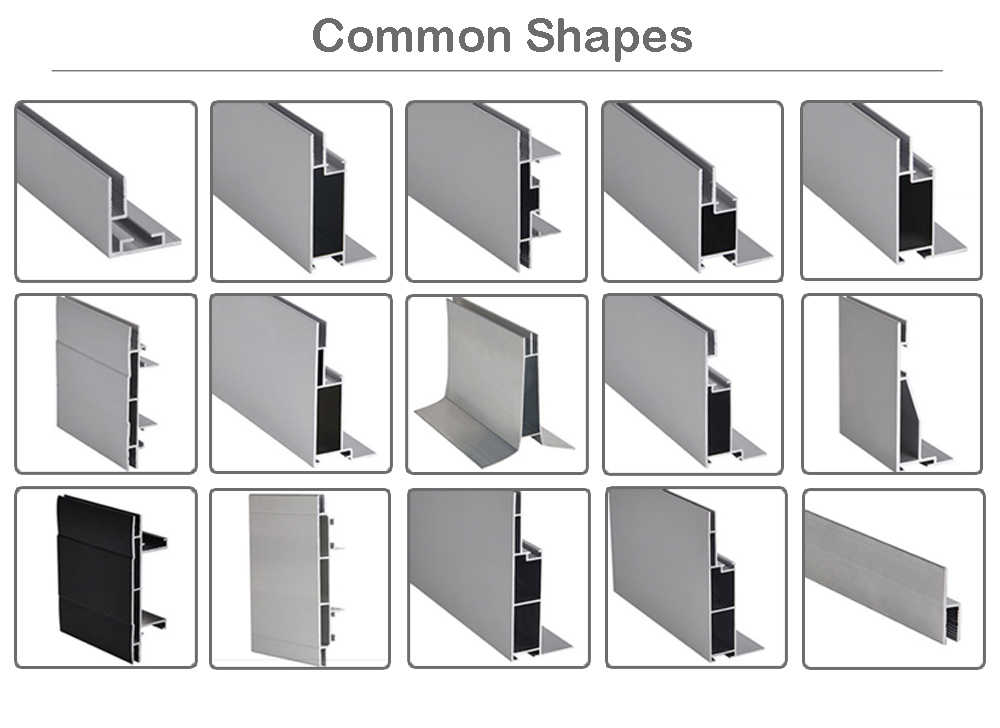

We offer a variety of sizes for aluminium sign frame extrusions with or without retainers. We have wide stocks good for raceway lids, double tees, retainers, half-round posts, and other applications.

Wellste increased our fabrication capabilities and extrusion inventories to produce custom aluminium sign frame extrusions. So, if you`re looking for any type of aluminium product, please choose Wellste to be your supplier.

For both outdoor and indoor uses, Wellste aluminium sign frame extrusions are completely suitable.

| Item Type | Aluminium Sign Frame Extrusions |

| Material | 1000series ~ 7000series aluminium |

| Temper | T3-T8 |

| Shapes | Strip, and customized |

| Application | For advertising display in a shopping mall, Metro, Airport, mobile shop and so on. |

| Type | Single side display, double sides display; Floor standing, Wall-mounted |

| Surface treatment | Anodizing, Mill finish, Electroplating, Polishing, Sand blasted, Powder coating, Silver plating, Brushed, Painted, PVDF etc. |

| Deep processing | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| Standard | GB, ASTM , AISI , DIN , BS, JIS |

| Certification | ISO9001 |

| Delivery Time | 15-20 days after sample confirmed & down payment, or negotiated |

| OEM/ODM | Acceptable |

| Service | 1. Free sample, Free design; 2. OEM/ODM available; 3. Custom-made request; 4. New design solution suggestion |

As a premier distributor of high-quality aluminium sign frame extrusions, Wellste engineers ensure the greatest quality fit, bend and finish to complete every project. Be with Wellste to have a one-stop solution for aluminium sign frame extrusions.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Usually, we produce grade 6063 aluminum alloy products, because they can reach most of your requirements for hardness or durability. If you have a special request for strength, grade 6061 is good enough for your project.

Sure! Our experienced technical engineers stand by to help you and will revert to you after making an evaluation based on your drawings. We support free design guidance in the initial stage and come back to you within 24 hours.

Yes! We have various surface finish treatments for your reference, including normal anodizing, hard anodizing, powder-coating and electrophoretic coating, and so on. We have our own color card and feel free to get it from our engineers.

It’s all up to your actual requirement. Usually, if we have the product in stock, we will arrange the delivery for you within a week. As to bulk production, it will be 25-30 days, especially for the customized aluminum extrusions.

Yes, we have more than 100 workers and are willing to help you assemble the products. Please give us the assembling instruction and we will assemble as you required. By the way, we have our own courier and will send the product to you directly.

Yes, but our MOQ is very low and we are also willing to support prototyping production for you in the developing process. It will be only 100 kg since we are looking for long-lasting cooperation with you in the first order.

Products You May Looking for

Wellste has abundant aluminum construction profiles in stock, we are capable to prepare fast delivery for you within 7 days or even quicker. The most common color for construction profiles is silver, we can also do customization for you based on your personal requirement.

Wellste LED aluminum extrusion has both high quality and elegant appearance, it is suitable for home or indoor decorations. Wellste cooperates with worldwide LED lighting companies and aims to offer a one-stop solution for you.

Wellste aluminum louver profile has high corrision resistance and won’t wear out or get scratches. It is suitable for your residential buildings, or even modern skyscraper curtain walls. Our technical engineers stand by to help you find suitable profiles.

Wellste corner LED profile is designed for your special degree lighting requirement including 45 degrees and 90 degrees and so on. We support extra accessories like mountings and two end plates, Wellsye corner LED profile is very easy to assemble and durable for your application.

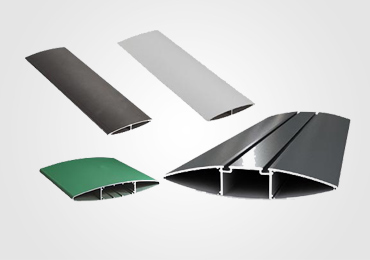

Wellste roller shutter profiles are in compliance with EU Standards and have a high quality of strength and soundproofing for your application. It is strong enough to protect your safety from breaking in. What’s more, we have a great many existing models for your reference.

Wellste is specialized in doing special customization based on your personal specification. Wellste experienced technical engineers are willing to guide your design improvement for free. We make evaluations based on your drawings and will keep in touch with you within one day.

Wellste aircraft aluminum extrusion is famous for its high precision and strength. We only choose high-stength aluminum alloys for your aircraft aluminum extrusions. Wellste has special CNC machining services for you, it ensures your aluminum components work well in application.

Wellste is confident to handle your project with any complicated shapes. Wellste technical engineers have devoted themselves to the aluminum extrusion area for more than 10 years and support free design or production possibility evaluation for you in the short time before your final bulk production.

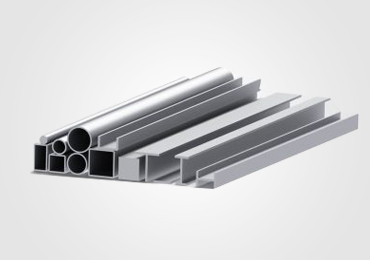

Wellste has all kinds of standard aluminum extrusion profiles you may need, including aluminum angle. Aluminum tube, aluminum plate, and so on. We also support customizing aluminum extrusions based on your drawing, our engineers can also design as you required.

Wellste: Your Reliable Aluminium Sign Frame Extrusions Distributor

Wellste is an ISO 9001 certified manufacturer and supplier of the highest quality aluminium sign frame extrusions.

This product is cut into different sizes, machinable and bendable to fit every construction project. We need your cooperation to make it happen.

Wellste aluminium sign frame extrusions are working with 1100, 2024, 2011, 2017, 3003, 5052, 5086, 5657, 6013, 6101, 6061, 6063, 6262, 7050, 6020, 7075, and 5005 alloy no.

Available finishes for aluminium sign frame extrusions are anodized, mill-finish, powder coated, and more.

Wellste does the heat treating, painting, anodizing, and even the full fabrication in producing high-quality aluminium sign frame extrusions.

From special shapes to simple components to create aluminium sign frame extrusions, quality is guaranteed.

Wellste is continuously improving our extensive inventory. As a result, we can now provide you with labor saving and more economical aluminum extrusion products for different construction projects.

Wellste has an extensive line of aluminium sign frame extrusions with custom shapes and sizes.

In the fabrication, whatever you demand, we are ready to accommodate. Our wide range of aluminum extrusions will give you almost all options in the industry.

Our company, Wellste, has more than 20 years of history and involvement in fabricating aluminium sign frame extrusions and other aluminum extrusion solutions.

Wellste is a team of dedicated engineers and staff, continually developing an extensive product line of aluminium sign frame extrusions to deliver across the world.

Our top goal is to exceed our customers` expectations with our customer support, order fulfillment, product qualities, etc.

Also, we have heavily trained staff and engineers help to ensure the durability and quality of our aluminium sign frame extrusions.

Wellste is your ONE STOP source for the best aluminium sign frame extrusions!

Don`t miss any of Wellste latest products!

Aluminum Sign Frame Extrusions: The Ultimate FAQs Guide

Aluminum sign frame extrusions refer to aluminum products used for making sign boxes or frames for a sign box.

You can use them in a wide range of interior and exterior signage, signage mounting, and displays among others.

This FAQ guide provides profound details regarding numerous elements of these aluminum by-products.

Ultimately, you’ll understand several aspects of these components, which come in handy in shaping your purchase decision-making process.

Aluminum Sign Frame Extrusions

Aluminum Sign Frame Extrusions

- What Aluminum Grade Do You Use To Manufacture Aluminum Sign Frame Extrusions?

- How do you Manufacture Aluminum Sign Frame Extrusion?

- Why Is Aluminum Suitable For Sign Frame Extrusions?

- Is There Size Limitations For Aluminum Sign Frame Extrusions?

- How Do You Control Quality Of Aluminum Sign Frame Extrusions?

- What Are The Available Color Options For Aluminum Sign Frame Extrusion?

- What Are The Available Surface Finishes For Aluminum Sign Frame Extrusion?

- How Much Does Aluminum Sign Frame Extrusion Cost?

- What Are The Main Applications Of Aluminum Sign Extrusions?

- Is There Shape Limitation For Aluminum Sign Frame Extrusions?

- What Are The Common Design Trouble Spots For Aluminum Sign Extrusions?

- What Is Ideal Extrusion Ratio In Aluminum Sign Extrusion?

- What Are The Mechanical Features Of Suitable Aluminum Sign Frame Extrusions?

- Are Aluminum Sign Frame Extrusions Durable?

- What Is The Recommended R-value For Aluminum Sign Extrusions?

- How Can You Customize Aluminum Frame Extrusions?

- What Are The Quality Standards That Aluminum Sign Extrusions Comply With?

- Are Aluminum Sign Frame Extrusions Weather-resistant?

- What Is Your Turnaround Time For Aluminum Sign Extrusions?

- What Is The Recommended Thickness For Aluminum Sign Extrusions?

- What Is The Suitable Tolerance Of Aluminum Sign Extrusion?

- What Is The MOQ When Buying Aluminum Frame Extrusion?

- What Are The Components Of Aluminum Sign Frame Extrusion?

- Which Dimensions Do You Need For Successful Aluminum Sign Frame Extrusions?

- How Do You Mount Aluminum Sign Frame Extrusion?

- Which Factors Enhance Efficient Aluminum Sign Frame Extrusion?

What Aluminum Grade Do You Use To Manufacture Aluminum Sign Frame Extrusions?

You can find aluminum sign frame extrusions in a wide variety of aluminum grades.

Essentially, this is vital since it broadens your choice options, making it easy for you to obtain the specific one you’re looking for.

The most commonly used aluminum grades at Wellste for these products include the following;

- 1100

- 2024

- 2011

- 2017

- 3003

- 5052

- 5086

- 5657

- 6013

- 6101

- 6061

- 6063

- 6262

- 7050

- 6020

- 7075

- 5005

All these aluminum grades feature different technical specifications. Thus, you will likely get aluminum sign frame extrusions with varying features depending on a specific grade you select.

How do you Manufacture Aluminum Sign Frame Extrusion?

We use aluminum extrusion process, just like the name suggests.

Extrusion is available in numerous techniques depending on the specific end product you intend to attain.

Nevertheless, aluminum sign frame extrusion can be done under the following extrusion methods;

Cold Extrusion

This is an extrusion process carried out at room temperature or slightly elevated temperatures. It is an ideal technique for manufacturing aluminum sign frames as long as the tooling is sturdy enough to endure stress formed by extrusion.

The advantage of cold extrusion is that it offers excellent strength due to cold working. It also provides by-products with closer tolerance and ideal surface finish among others.

Hot Extrusion

It is an extrusion process carried out at relatively high temperatures ranging from 50-75% of the aluminum’s melting point.

This process utilizes pressure levels ranging from 35-700Mpa.

Due to high pressure and temperature experienced in this type of extrusion method, chances of machine tear and wear are high. Therefore, there is a need for good lubrication to maintain die life.

Ideally, this aluminum sign frame extrusion method is comparatively costly than cold extrusion technique.

Hydrostatic Extrusion

It is another fundamental method you can use to make aluminum sign frame extrusions. This technique incorporates a pressurized liquid surrounding the workpiece, thus reducing force requirements and impact extrusions.

The pressurized liquid uses a high-velocity metal slug to force the aluminum workpiece into the respective die. In all these methods, aluminum extrusion billets are preheated, extruded, surface coated, and cut accordingly.

Why Is Aluminum Suitable For Sign Frame Extrusions?

Technically aluminum is used in a wide range of sign frame extrusions in different commercial, industrial and residential settings.

This material creates by-products guaranteeing efficiency, performance, durability, and reliability in its different applications.

Here are some important reasons why aluminum is an ideal option for sign frame extrusions;

Provides Different Shapes And Designs

You can easily obtain a wide range of sign frame extrusions from aluminum.

Aluminum is relatively flexible, thus allowing you to mold it to different configurations.

It is also available in different color shades and surface finishing, which is essential in selecting what best fits your preference.

Aluminum Sign Frame Extrusion Design

Offers Excellent Strength To Weight Ratio

Aluminum is naturally strong and, at the same time, lightweight. It features low density making it easy to derive slim profiles strong enough for signage.

The excellent strength also allows you to create various unique shapes and designs of your signage frames.

Guarantees Safety

Aluminum material provides optimum safety for the framed signage. It is relatively difficult to vandalize particular signage made using an aluminum framing component.

Provides Excellent Durability

Typically, aluminum sign frames are easy to maintain.

The nature of this material allows it to withstand various harsh environmental and mechanical conditions without wearing out.

In essence, it is durable and can thus last for as many years as possible without degrading or deforming.

Energy-efficient

Aluminum sign frame extrusion features thermal strips that regulate heat gain or loss from the surrounding.

Is There Size Limitations For Aluminum Sign Frame Extrusions?

No, notably various signage projects require different sizes of aluminum sign frames.

In most cases, the design construction of the particular signage is what determines the exact size of an ideal aluminum sign frame size.

Thus, different batches of these aluminum profiles used as sign frames will be of different dimensions.

Nevertheless, you can always find custom sizes, which fit your respective signage project. This is the best alternative since it guarantees efficiency.

How Do You Control Quality Of Aluminum Sign Frame Extrusions?

Several interventions are always put in place to ensure the final product of aluminum sign extrusions meet the minimum quality standards.

This takes place from material sourcing, manufacturing process, handling, and delivery to the customers.

Essentially, most of the stipulations revolving around quality control in production process of these aluminum products are enacted by regulatory bodies.

However, we undertake specific measures at the manufacturing level to ensure quality control practices are in place.

First, we ensure we source the aluminum raw materials from reputable dealers certified by the regulatory body.

It is an important quality control measure since it allows us to follow up with the supplier if quality concerns arise during or after manufacturing.

Secondly, all our machinery involved in aluminum sign frame extrusion making is frequently inspected to ensure they meet required conditions.

In essence, it helps to maintain the machines in a good state to guarantee safety and quality in the overall production process.

Thirdly, we hire knowledgeable, experienced, and competent employees in different departments of the organization.

Moreover, the employees often undergo vigorous and frequent trainings regarding quality control systems and measures. It ensures they execute all the relevant quality checks and control other vital elements that would improvise quality.

We have a meticulous quality inspection process, which includes custom gauging.

What’s more, we observe different aluminum extrusion services as we preserve ISO 9001:2015 across all separate sections of the manufacturing.

Before shipping the products to their respective destinations, we also inspect the finished parts using advanced testing devices.

What Are The Available Color Options For Aluminum Sign Frame Extrusion?

They are quite several, and the choice for an ideal one is entirely dependent on your project demands and your preference.

Ideally, you can easily infuse extruded aluminum parts by dipping them in a specific color paint to attain the desired shade.

In essence, it is advantageous since it broadens your choice options as far as finding a suitable colored aluminum sign frame is concerned.

Nonetheless, here are some of the available color shades of aluminum sign frame extrusion you’re likely to come across;

- Grey

- Titanium

- Silver

- Nickel

- Bronze

- Green

- Champagne

- Golden yellow

- Black

- White

What Are The Available Surface Finishes For Aluminum Sign Frame Extrusion?

They are quite a number, and the ideal choice is dependent on different factors surrounding the signage project.

Some of the commonly used options include the following;

Mill Finish

This refers to a surface finish of aluminum sing frame on its natural appearance without any additional coating.

Ideally, mill finish exhibits this component in natural aluminum color shade.

Mill Aluminum Sign Frame Extrusions Finish

Electroplating

It is a surface finish you attain by fusing aluminum sign frame profile on another one by hydrolysis.

Essentially, it involves application of a direct current to form a special coating on the surface material.

This process partially dissolves the aluminum metal and creates a strong chemical bond between the materials.

Anodized Surface Finish

This refers to an electrochemical process for preserving aluminum sign frame profile finish. Anodized surface finish provides an enhanced corrosion resistance coating formed by an oxide layer.

It also creates a decorative dirt-resistant surface with durable gloss and an electrically insulated layer.

Sandblasting Surface Finish

It refers to aluminum surface pretreatment forming a matt finish by forcing a stream of abrasive steel beads at extremely high pressure.

The aluminum sign frame surface material attains smooth mill finish profiles without any damage.

Powder Coating Finish

This surface coating results from electrostatically charges powder fusing with smooth painted coating in a curing oven.

The powder, which is a mixture of finely milled resin and pigment, is then sprayed on the surface material of aluminum sign frame profile.

Powder coating finish provides resistance to UV protection and corrosion but with different color variants.

Triacid Polished Surface

This refers to a chemical polishing method, which entails dipping profiles into a strong oxidizer to obtain an ultra-bright mirror finish.

Triacid polishing means use of three different acids, which include phosphoric, nitric, and sulfuric.

This surface coating involves mechanically polishing the aluminum sign frame profile before triacid polishing.

It allows the material to attain different glossy finishes.

Brushed Aluminum Finish

It is a surface coating option, which forms a unidirectional satin finish and providing silky matt on the aluminum sign frame profile.

It provides the material a unique appearance since it retains metallic lustre.

How Much Does Aluminum Sign Frame Extrusion Cost?

There is no fixed price for any aluminum sign frame extrusion.

Ideally, numerous elements determine the exact amount of money you pay to acquire a particular design of this part.

Some of the cost-determinant factors include the following;

- Order Quantity – In most instances, manufacturers, including Wellste, often provide reasonable discounts on large quantity purchases and vice versa.

Therefore, it is cost-effective to purchase more quantities of these parts for better savings than buying small quantities.

- Manufacturer – Ideally, different brands always price their products differently based on several factors.

However, relatively popular brands are more likely to price their aluminum sing frame extrusions higher than less known ones.

- Aluminum Grade – Evidently, aluminum is available in multiple grades, and all have unique features suitable for specific projects or settings.

Thus, the price is likely to depend on the particular aluminum grade used for making the sign frame extrusion profile.

- Design Construction – In many cases, aluminum sign frame extrusions are available in custom designs.

Fundamentally, the needs and preferences vary among different customers, thus the essence of custom designs.

However, the price always depends on the level of customization required on a particular aluminum sign frame you are purchasing.

- Surface Finishing – Aluminum sign frame extrusion profiles are available in different surface finishing based on your project needs and preference.

Essentially, each type of surface finishing influences the actual cost you’ll need to pay, given they all exhibit different features.

What Are The Main Applications Of Aluminum Sign Extrusions?

Notably, acrylic sign extrusions are used in numerous applications across different commercial, residential and industrial settings.

You can use them for virtually any sign or exhibit for both interior and exterior applications.

However, the main ones you are likely to come across include the following;

- Advertisement

- Post and panel system

- Promotional signage

- Trade shows

- Wall mount

- Canvas sign frames

- Exhibits

- Billboards

- Site identification

- Product display

- Directional signage

- Box sign systems

Is There Shape Limitation For Aluminum Sign Frame Extrusions?

No, you can always find aluminum sign frame extrusions in a broad range of shapes and designs.

Ideally, extruded aluminum, which is the primary material for making these components are relatively flexible and lightweight.

Thus, you can easily mold or customize it to fit the specific configurations matching your particular requirements.

What Are The Common Design Trouble Spots For Aluminum Sign Extrusions?

Creating and executing aluminum sign extrusions at a time can be challenging.

You need to figure out the best ways to circumvent the usual trouble spots when designing aluminum sign extrusions.

Some of these common designs trouble spots are as follows;

The more unbalance or unsymmetrical the profile shape is, the less likely it is to remain straight or hold curves and overall dimensions.

Wall-thickness also tends to cause problems in some instances.

An ideal aluminum material wall thickness to use should be at least half of the thickest within a profile.

Notably, a wall with thickness discrepancies often cools at varied rates during heat-treat quenching, which adds to distortion.

The more the minimum wall thickness goes up, the larger the extrusion shape gets. Narrow shapes with deep gaps are also a recipe for problems.

Similarly, not all aluminum sign frame extrusion profiles with hollow shapes must be produced on a hollow-type die.

If not, die-tongue area can hardly withstand extrusion pressure force and tends to bleak.

What Is Ideal Extrusion Ratio In Aluminum Sign Extrusion?

Extrusion ratio refers to a measure of cross-sectional areas of the die shape opening to that of a container through which the billet is pushed.

Factually, a billet with a relatively large diameter pushed through a small die opening has a high reduction ratio.

The normal extrusion ratio for soft aluminum alloys is limited to 100:1, whereas hard aluminum alloys are 35:1.

However, the normal extrusion ratio range for soft aluminum alloys is from 10:1 to 100:1, and for hard aluminum alloys is from 10: to 35:1.

Aluminum Extrusion for Sign Frame

What Are The Mechanical Features Of Suitable Aluminum Sign Frame Extrusions?

Intrinsically, forming aluminum sign frame extrusion profiles entails altering most parts of the material’s physical features.

Even so, a meticulous formation of these parts introduces distinctive cross-sections in the profile to enhance versatility.

Some of the mechanical characteristics of a typical aluminum sign frame extrusion include the following;

- Non-corrosive – These parts are invulnerable to corrosion arising from any form of chemical substance.

It can thus endure harsh environmental conditions without wearing out, making it relatively durable.

- Lightweight – The weight of extruded aluminum metal is 1/3 less of iron or brass. This shows it is pretty lightweight.

Ideally, its lightweight nature never compromises its overall strength. Thus, it is suitable for creating different sign frames ideal for a broad range of applications.

- High impact strength – Manufacturing of aluminum sign frame extrusions involves the aging process.

This process reinforces the strength of base material, making it possible to withstand mechanical pressure without ruining its dimensions or form.

- Easy alloying – You can easily form different alloys using aluminum since it is compatible with numerous metals.

Simple formation processes such as riveting, welding, adhesive bonding, and brazing are common for alloying aluminum.

- Highly recyclable – You can use aluminum sign frame extrusions as many times as possible and still attain desired results.

The base material is recyclable irrespective of the years it has been in use or exposed to different elements.

Are Aluminum Sign Frame Extrusions Durable?

Yes, the material used for making this sign frame extrusions is sturdy and exhibits excellent resistance to several weather and mechanical elements.

Extrusion process, which this aluminum goes through, reinforces its strength during aging.

Aging also enhances the elasticity of the base material. It also guarantees consistent precipitation of particles on the surface material of aluminum.

Thus, this makes aluminum sign frame extrusions relatively durable. A typical one can last for at least 10 years without degrading, deforming, or wearing out.

What Is The Recommended R-value For Aluminum Sign Extrusions?

R-value is simply the measurement of a material’s capacity to withstand heat flow from one side to another.

In essence, it is a value portraying the effectiveness of insulation level.

The highest number often represents more effective insulation. However, there is no defined R-Value for aluminum sign frame extrusions.

The framing component of these parts often determines the general thermal transmittance. Moreover, a new standard is used for testing the complete aluminum sign frame, including all the framing components.

ASTM C1363, which is the new standard, gives lower results but often more accurate to the specific installed conditions.

Wall thickness of insulating material on the surface of aluminum sign extrusion profiles also influences the R-Value.

How Can You Customize Aluminum Frame Extrusions?

You can use several techniques to modify aluminum frame extrusion to ensure it meets your preference. Ideally, aluminum is a highly machinable material making it easy to attain the ultimate results in your customization quests.

The common methods you can use when customizing this equipment include the following;

- Cutting to size – Merely refers to slicing the size of aluminum frame extrusion by reducing it to attain a particular dimension.

- Stamping – This customization technique involves placing a sheet metal material in a blank or coil to form a stamp. It leads to formation of the material into an ideal shape.

- Drilling – It is a cutting process, which involves using a drill bit and a drilling machine to form a circular cross-section hole on surface material.

- Welding – This customization technique involves joining of different materials using ultra-heat to melt the component together. The two or more parts fuse and become intact once they cool.

- Milling – It is a process that uses a rotary cutter to remove material by advancing a blade into aluminum frame profile workpiece.

What Are The Quality Standards That Aluminum Sign Extrusions Comply With?

They are pretty several, usually determined by a wide range of elements revolving around these components and manufacturing process.

These quality standard certifications are often approved and published depending on how they influence different factors of the products. Even so, they apply differently to various regions and specific markets.

The commonly used ones include the following;

EN 12020-2

This is a European standard specifying specific tolerances, dimensions, and forms or aluminum sign extrusion precision profiles.

It primarily applies to aluminum sign extrusions without surface treatment.

BS EN 12020

It is also a European standard, which equally specifies the tolerances on dimensions and form of extruded profiles.

EN 755-9

This standard specifies tolerance on dimensions and forms of aluminum and its specific related alloy extruded sign frames.

It applies to extruded aluminum sign frames for different applications.

ISO 9001

It is a standard issued by the International Standards Organization, which specifies requirements for a particular quality management system.

Essentially, this standard enables manufacturers to exhibit ability to produce quality products consistently.

The bottom line is aluminum frame extrusions comply with different quality standards.

However, it is vital to confirm with your particular country to establish whether these products meet the stipulated quality standards before importing.

Are Aluminum Sign Frame Extrusions Weather-resistant?

Yes, aluminum material has excellent weatherability making its respective sign frames resistant to different weather elements.

In essence, most applications surrounding aluminum sign frame extrusions are outdoors.

However, the design and properties of these parts make it possible for them to endure harsh weather conditions without wearing out.

Outdoor Extruded Aluminum Sign Frame

What Is Your Turnaround Time For Aluminum Sign Extrusions?

Several elements often determine the actual production turnaround for aluminum sign extrusions’ order.

Typically, new extrusion tools ordinarily take about 2-3 weeks and additional 1-2 weeks for initial production material.

If you make your order from our vast library of standard aluminum sign extrusion shapes, the lead time will be relatively short.

It would be more or less same day as any other repeat order based on the prevailing manufacturing capacity.

What Is The Recommended Thickness For Aluminum Sign Extrusions?

There is no fixed material thickness for aluminum sign extrusion. It varies on several factors, including the design construction of the specific signage.

Aluminum sign extrusion thickness, nonetheless, influences various performance and durability aspects of these sign extrusions.

Even so, the recommended minimum wall thickness should be at least 0.8mm.

What Is The Suitable Tolerance Of Aluminum Sign Extrusion?

The ideal tolerance of aluminum sign extrusion is as outlined in BS EN 755-9:2001 standard. Nonetheless, different reputable manufacturers like Wellste often offer most tolerances that would improve this standard.

Essentially, instances which require tighter tolerances, the manufacturer may work on standards as outlined in BS EN 755-9:2001.

In other circumstances, based on size and complexity of profile makes it a bit tricky to enhance the tolerance as set in BS EN 755.

As such, the suitable way to establish an excellent tolerance of aluminum sign extrusion is by looking over your proposed design. Notably, achievable tolerances on these aluminum sign extrusion are based on a specific profile.

What Is The MOQ When Buying Aluminum Frame Extrusion?

Several elements influence the particular MOQ when purchasing aluminum frame extrusion. Many manufacturers often tag a specific MOQ on customized aluminum frame extrusions.

Essentially, custom designs are quite involving and unique thus only designed for a specific customer.

On the other hand, standard design may or may not have MOQ depending on the manufacturer you are purchasing from.

Nevertheless, you can always negotiate and agree on a suitable MOQ with a manufacturer you are purchasing these components from.

Most companies tend to be relatively flexible, giving you the leeway to negotiate for a fitting MOQ when purchasing aluminum frame extrusion.

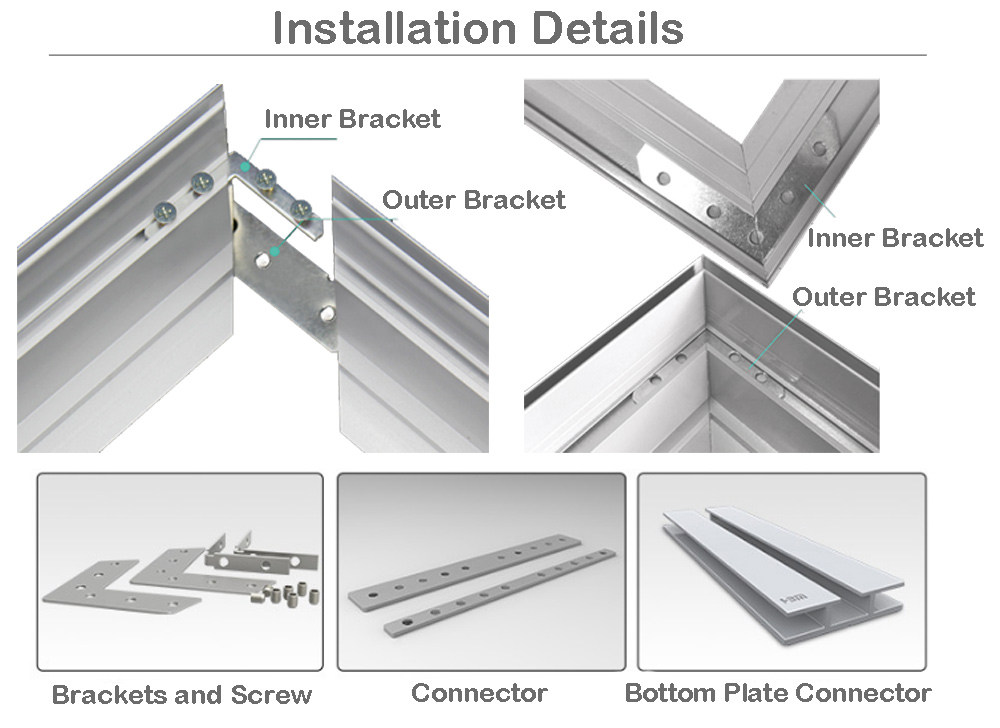

What Are The Components Of Aluminum Sign Frame Extrusion?

They are several, and the specific one usually depends on the design construction of a particular aluminum sign frame extrusion.

Some of the common ones include the following;

- Lid covers

- Dividers

- Hinge brackets

- F tracks

- Tees and double tees

- Hidden hinge retainer

- H channel

- Sign hinge

- Sign cabinet extrusions

Which Dimensions Do You Need For Successful Aluminum Sign Frame Extrusions?

- Circle Size – It is the smallest circle completely enclosing the profile of aluminum sign frame. This dimension is essential in determining the press size required to produce the shape.

- Factor – Refers to ratio of circle size to the surface perimeter.

- Extrusion Ratio – It is the ratio of cross-sectional areas of the die shape opening to that of a container through which billet is pushed.

How Do You Mount Aluminum Sign Frame Extrusion?

Aluminum sign frame extrusion includes two different designs; slide-in and bolt-in styles.

When mounting slide-in frames, you won’t necessarily need to screw the sign panel into frame. Instead, you simply slid it in from the top easy sign exchange.

Additionally, you may want to bolt the sign into place to ensure it stands up properly upright.

For bolt-in aluminum sign frame extrusions, the design features screw holes along all other edges to secure a sign.

Drill holes into the sign to match up against holes provided on sign frame.

Use a bolt to secure the sign to the frame to get the most secure way to display signage for longer.

Slide-in Aluminum Sign Frame Extrusion

Which Factors Enhance Efficient Aluminum Sign Frame Extrusion?

There are several helpful design practices you can execute to ensure you attain a better final aluminum sign frame extrusion.

These practices include the following;

- Practicing symmetry and restraining asymmetrical details as much as possible

- Avoiding or restricting hollows

- Minimizing the perimeter or cross-section ratio

- Proper utilization of grooves, webs, and ribs

- Aligning balanced walls

- Generous tapers

Now, it’s time to hear from you.

In case you have any questions or inquiries, talk to Wellste team now.