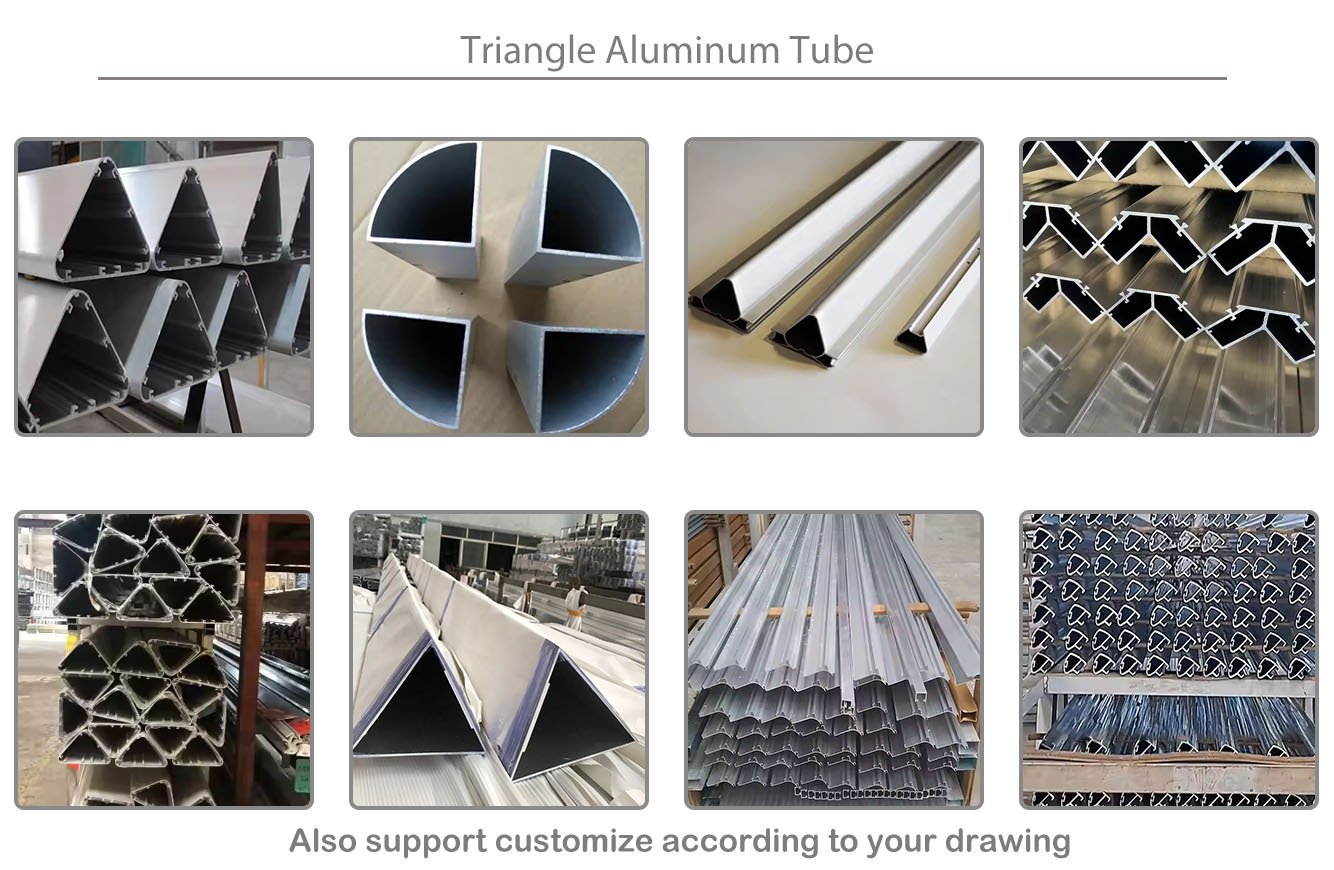

Triangle Aluminum Tube

- 100KG low order volume ONLY

- One-stop finalize from idea to manufacturing

- 3-5 days Fast Shipment support Global Shipping

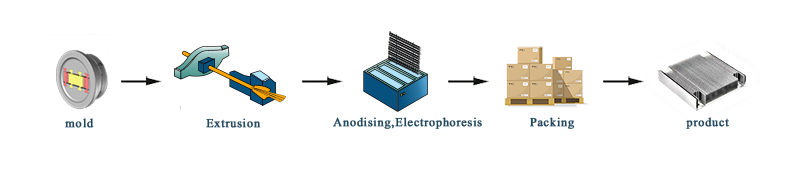

Manufacture In Technology

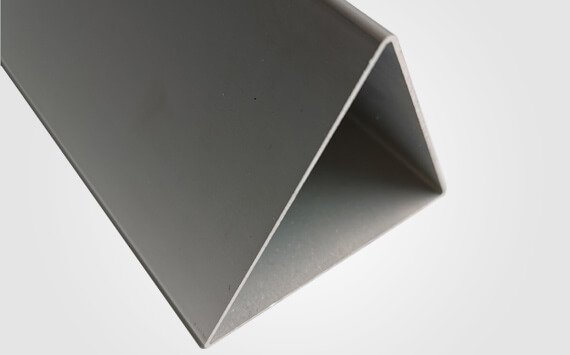

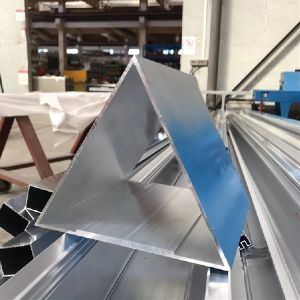

Extruded Triangle Aluminum Tube

Wellste’s triangular aluminium tubes are manufactured using 10,000 tonne extruders, typically using 6061, 6063 and 7075 bars, and can be customized to different diameters, wall thicknesses and lengths according to customer needs, with high tooling requirements.

5-500mm

(0.196-19.68in)

Outer diameter range

1-100mm

(0.039-3.94in)

thickness

1-12m

(3.28-39.4ft)

length

Send your inquiry Now!

At Wellste, you will find the right triangle aluminum tube solutions!

The ideal alloy no. for triangle aluminum tube is 1xxx, 2xxx, 3xxx, 5xxx, 6xxx, 7xxx series. Wellste brings endless benefits of a triangle aluminum tube to your applications. For example, Wellste triangle aluminum tube is flexible and lightweight, which allows them to be shaped easily.

Projects

Actually, there’s a lot of features and great advantages of Wellste aluminum tube that brings your projects to be done readily. Plus, we have excellent manufacturing capabilities to guarantee a high-quality and well-made triangle aluminum tube.

Wellste triangle aluminum tube is an eco-friendly and non-toxic material. Such features make them ideal in the food industry. They can also withstand temperatures ranging from 600 degrees Fahrenheit and are non-combustible, ideally suited for aerospace and welding projects.

Actually, there’s a lot of features and great advantages of Wellste aluminum tube that brings your projects to be done readily. Plus, we have excellent manufacturing capabilities to guarantee a high-quality and well-made triangle aluminum tube.

We provide made to order triangle aluminum tube varies in numerous surface treatment, color polishing, alloy no., sizes, and length, guaranteed to be worked in any intended applications.

| Product Name | Triangle Aluminum Tube |

| Description | Triangular aluminum tube is a hollow aluminum alloy tube with a triangular cross-section (equilateral, right-angled or unequal). |

| Meterial | Aluminum alloy 6061, 6063,6082, 7075, etc. ,ADC12, A380 ingots |

| Temper | T4、T5、T6 |

| Quality Standard | GB/T 5237-2008 ,GB/T 6892-2015, GB/T 14846-2014 |

| Length | 1-12m |

| Finish | Mill-finish Anodized Powder coated,Flectropheresis, Woodarain, Brushed, Polishing |

| Open Mould | 10-15days |

| Production Time | 20-25days |

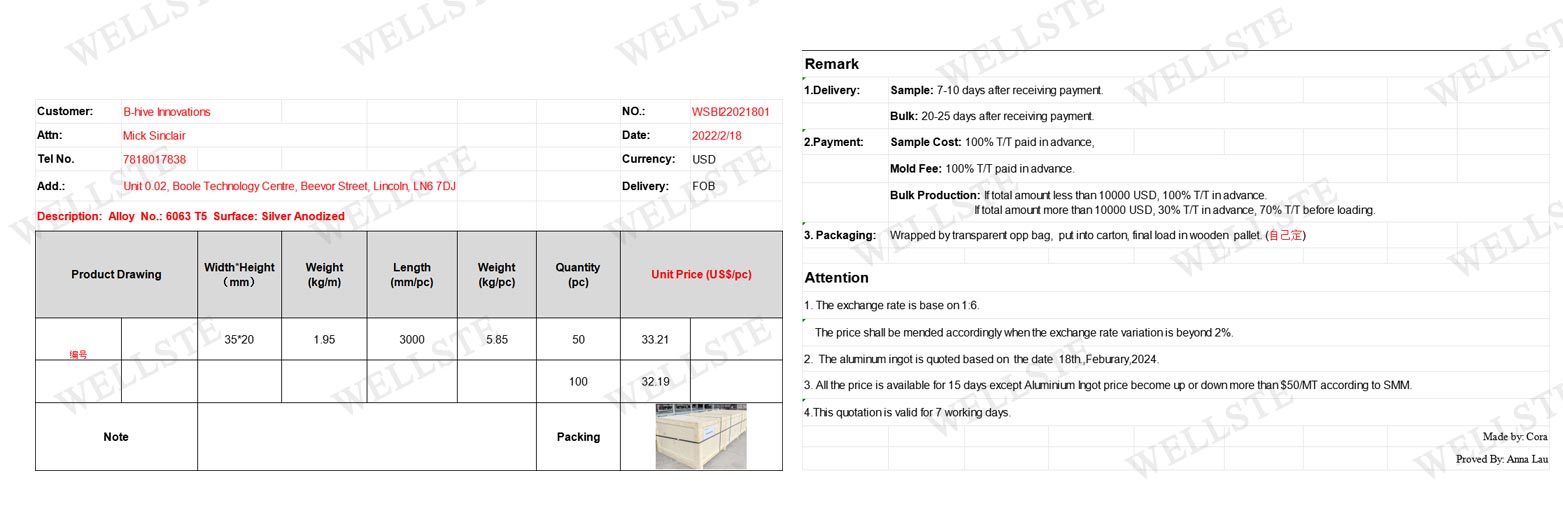

| Payment | TT, L/C, etc |

| MOQ | 100KG |

| Deep process | CNC,drilling, milling, cutting, bending, tapping, welding, assembling, punching |

| Standard Packaging | PE shrink film,Non-woven Fabric, Craft paper, Carton, Or customized packing |

If you’re interested here, we freely present bending capabilities, design information, and heat-treating information. We work eagerly with you to produce flawless designs for your products.

Call us for fast shipping, low prices, and great service!

Typical Alloy

Wellste triangle aluminum tube is produced from 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, and 7000 series alloy no. This product is one of the most common shapes for standard and custom aluminum extrusions.

6000 series

6061, 6063, 6082, 6005, 6005 etc

7000 series

7075, 7001,7003, 7005 etc

Wellste: Your Leading Triangle Aluminum Tube Solution Supplier

Wellste has a huge inventory of triangle aluminum tubes to be shipped throughout the world. We are in fact specializing in producing hard-to-find triangle aluminum tubes with excellent polishing, quality, and great pricing.

Wellse, working in China is 20 years in providing the unique and best triangle aluminum tube you need. No matter how large or small your orders, we can fabricate and bring them to you. In any case, we can provide sample designs. We can manufacture according to your requirements as quickly as we can.

At Wellste, you can find a satisfying triangle aluminum tube in many surface treatments including anodizing, electrophoresis coating, PVDF coating, standard mill finish, and customize as per your request. We can also polish our triangle aluminum tube into different colors such as red, silver, gold, black, blue, etc. If you require any custom color, we can make it for you! Just send us your details and specifications.

Widely Usage Scenarios

Wellste has a complete range of end-to-end engineering, design, and manufacturing solutions of triangle aluminum tubes for different applications. Extruded aluminum tubings have a great role to play in the field of construction, electron, transportation, furniture, spaceflight, energy, and many more.

There are so many applications done with Wellste triangle aluminum tube. Mostly, you can find them in the places where the wall and the ceiling come into contact, wall joints, window openings, furniture, niches, kitchen sets, and many more.

You can benefit Wellste triangle aluminum for decorative elements, commercial equipment, furniture, food industry, aviation, electrical, medical, recreation, etc.

construction

transportation

furniture

spaceflight

Contact us to get a free quote and more expertise about custom aluminum extrusion.

Triangle Aluminum Tube with easy

Tell us what you need

Get Solution &Quote

Mass Production