Aluminum is all around you—the subway railings, the skyscrapers elevators, and even larger airplanes. But have you noticed the different finishes in each of these applications? They’re not just for aesthetics but serve a more meaningful engineering purpose.

According to the European Aluminum Anodizing Association and MRFR, about 25% of all aluminum produced is anodized and MRFR also suggests aluminum mill finish has a global market share of about 60%. So, why do manufacturers anodize aluminum? Is mill finish not good for certain applications?

In this article, we will find why you’d choose to anodize aluminum, define mill finish aluminum, and determine the best finish for your project.

What Is Mill Finish Aluminum?

Mill finish aluminum is aluminum in its natural appearance. ‘Mill finish’ comes from the fact that the finished aluminum comes directly from the rolling mill without being chemically treated or having its surface finish altered. For details, refer to our article about Mill Finish Aluminum.

Mill-finished aluminum can also be thought of as raw aluminum. Mill finish is produced when aluminum billets are processed into aluminum sheets or aluminum extrusions are produced through dies.

Mill finish aluminum has an undertoned matt silver metallic color with visible die lines and imperfections.

Applications of Mill Finish Aluminum

Mill finish aluminum is one of the widest-used aluminum finishes because of how easily it can be recycled. It has many applications in the following industries.

Construction

Mill finish aluminum is used in buildings as aluminum trim, window frames, door locks, gutters, and drains.

Electrical Components

Mill-finish aluminum is not the best electrical conductor when compared with metals like copper or iron but compared with other aluminum finishes like anodized aluminum, it offers better conductivity.

Aluminum Products

Mill finish aluminum is used anywhere that requires the properties of aluminum like corrosion resistance and durability without much attention to aesthetics. In consumer goods, aluminum foil, cans, and packaging are all examples of mill-finished aluminum.

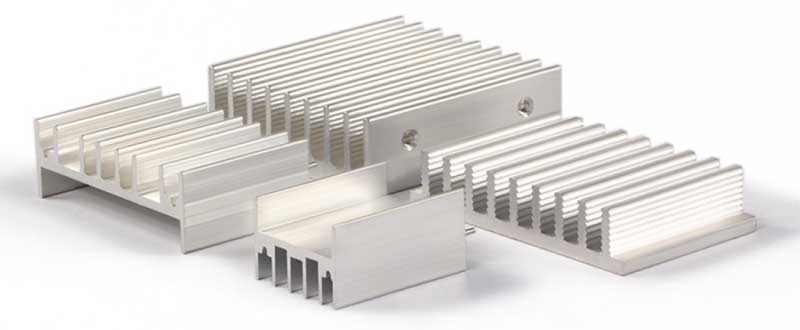

Aluminum Extrusion

Extruded aluminum, produced through hydraulic extrusion processing, is frequently utilized directly from the extrusion press in the construction of panels and railings as aluminum extrusions.

Mill Finish Aluminum Advantages

Here are the benefits of using mill-finish aluminum. These are the reasons you’d consider mill finish aluminum for your project.

- The biggest reason to choose mill finish is how cost-effective it is. Using raw aluminum is the cheapest way to complete your projects.

- Mill finish aluminum is flexible. It can be rolled and shaped into many products.

- Mill finish aluminum is recyclable

- Mill finish aluminum is corrosion resistant due to the aluminum oxide layer

- It has a thin aluminum oxide coating

- Mill finish has an organic aluminum look without any surface treatments.

Mill Finish Aluminum Disadvantages

Mill finish aluminum is an economical choice that fits many requirements. However there are a few reasons to avoid mill finished aluminum.

- Mill finish aluminum has an uneven surface with visible marks, spots, and die lines

- It has silvery white metal remnants which is the aluminum oxide color. Uneven surface grains highlight the aluminum oxidation.

- Aluminum mill finish can be field primed and painted but the paint can be chipped away easily.

- The oxidation layer can be easily removed

- There’s no abrasive resistance

- It is not suitable for marine applications because salt and extended exposure to moisture can result in excessive oxidation and rust marks.

What Is Anodized Aluminum?

Anodized aluminum is ordinary mill-finish aluminum with a protective oxide coating that is grown from the aluminum substrate in an electrochemical process. For details, refer to our article about Anodizing Aluminum.

The difference between anodized aluminum and mill finish aluminum is that anodizing is a type of surface treatment that adds on the protective layer and improves the properties of aluminum. Some of these properties include durability, abrasion resistance, corrosion resistance, color retention, and surface finish.

What Is The Anodizing Aluminum Process

Anodizing aluminum has many benefits that give a protective finish. The electrolytic process has the following steps.

Anodizing aluminum starts by taking aluminum products like aluminum extrusions, parts and railings and loading them onto racks.

Step 1 Pretreatment

Before anodizing aluminum, it is important to remove any debris and impurities from the surface. This is achieved using an alkali bath that removes built-up dirt, wax and oil from the surface.

Step 2 Etching

Anodizing essentially builds on top of the surface. For this reason, an acidic solution is used to etch away a micron-level layer of aluminum to get a smooth surface.

Step 3 Anodizing

Anodizing involves submerging the aluminum into an electrolyte of sulphuric acid and passing an electric current. Here a simple chemical reaction rapidly develops a thick protective layer over the aluminum surface. When oxygen ions in the solution interact with aluminum, they create a layer of aluminum oxide that possesses both corrosion resistance and abrasion resistance.

Anodizing process is not limited to aluminum and many other metals can be anodized. Anodized gold and anodized bronze are popular examples.

The difference between mill finish and anodized surface is the accelerated oxidation process through an electrolyte.

Anodized Aluminum Advantages

- Anodized aluminum is corrosion-resistant. Anodized finished products are less likely to corrode with moisture and salt because of their oxide coating thickness.

- Anodized aluminum has pores that can retain dyes and paint deeper in the oxide layer. The honeycomb pores can also retain oils for lubrication

- Anodized aluminum has better adhesive properties

- Andozing aluminum enhances UV and sunlight protection

- It is more abrasive-resistant

- Anodized aluminum can be colored black, bronze, or golden

- Anodized aluminum is harder than aluminum in its unpolished state

- It has a more durable surface

- Color achieved by anodizing process does not chip or scratch

Anodized Aluminum Disadvantages

- Anodizing process is expensive compared for small orders

- Increased hardness of metal means less flexibility.

- Anodizing can produce different shades of colors. There will be color variation in aluminum products

Anodized Aluminum Applications

Aluminum and anodized aluminum is widely used in various industries. From extrusion products to complex parts and components, anodizing surface treatment can be done on anything.

Construction

Anodized aluminum is used in the construction of buildings. Aluminum curtain walls, exterior decor, doors, and roofs all require anodizing to sustain the weathering effects.

Electrical Components

Anodized aluminum is used to produce electrical housings and casings. Laptop chassis, phones, TVs, and washing machines all make use of the corrosion-resistant anodic coating.

Automobile Industry

Anodizing aluminum also used for Automobile Industry, such as car roof rack, Car wheels,Caravan Aluminium Extrusions, rims, body, and number plates

Consumer Products

There’s a wide variety of consumer products like furniture, beds, lights, covers, etc. that use anodized aluminum.

What is Clear Anodized Aluminum?

At Wellste, we have a state-of-the-art anodizing facility that can produce both clear anodized aluminum and color anodized.

The difference between clear anodized and colored anodized is the addition of pigment during the electrochemical process.

Clear anodized aluminum has a silvery metallic shine with an oxide layer and colored anodized aluminum has the same thickness oxide layer with color.

The anodizing process produces a porous honeycomb structure in the oxide layer that can soak pigment into the pores. Then a nickel acetate solution seals the pores permanently trapping the color. Clear anodized has these pores unfilled with any pigment, which can lead to better lubrication as oils can seep into these pores when compared with raw aluminum.

Anodized Or Mill Finish Aluminum Extrusions?

The extrusion process for both anodized and mill finish is the same. Aluminum passes through a shaped die producing different extrusion profiles. The difference between mill finish and anodized aluminum extrusion products is the anodic surface treatment.

Anodized extrusions offer better corrosion and weather resistance, color options, and increased hardness and durable finish. However, that’s not necessarily a good thing because increased hardness makes aluminum extrusions difficult to work with, and for indoor use and decor, an extra protective coating serves no purpose.

When you decide between clear anodized or raw finish aluminum, it all comes down to your application and how effectively will your project make use of the advantages offered by clear anodization.

If you’re confused and in need of an expert opinion you can reach out to our professional team and get assistance within 24 hours.

Conclusion

Aluminum produced at a factory has a mill finish with spots, marks, and an uneven surface. It has the protective coating and corrosion resistance associated with aluminum but the coating thickness is very small. Anodizing enhances the naturally occurring oxidation of aluminum to get around 0.1 mm thick coating that can resist abrasions.

This coating enhances many mechanical properties of aluminum and is clear. This means after the extrusion process and anodizing, the aluminum still retains its color. During the process, a colored finish can be applied for aesthetics.

Find Your Aluminum Product Solutions With A Free Query

Have you decided you want your next project to be lightweight and long-lasting? Is aluminum your choice? Great! Not only is it 100% recyclable but we at Wellste have a decade-long history of environmentalism and professionalism when working with aluminum.

Take a look at our range of already-made products, or send us a query and get in touch with a personal contact agent for free.

FAQ

- Which is better aluminum or anodized aluminum?

Anodized aluminum is better than raw aluminum because it has better corrosion resistance, thicker protective coating and it can be clear, meaning you wouldn’t notice it.

- How do you protect a mill finish of aluminum?

Mill finish of aluminum is naturally protected by the oxide layer on the aluminum. For better protection, surface treatment like anodizing, PVDF coating, and painting can prolong the aluminum mill finish.

- Does mill finish aluminium corrode?

Yes, mill finish aluminum can corrode easily under moisture and when exposed to weather elements. It has a natural barrier to corrosion but it is not as effective as anodizing.