Design phase communication

We received an Extruded Aluminum Enclosure inquiry from a Canadian customer on 31.3.2022, who is mainly engaged in the lighting industry, We called this customer as ABC company.

What are the types of electrical enclosures?

ABC company asked what kinds of electrical enclosures Wellste can do, we can do 4 types electrical enclosures:

- Split-body with flanges Extruded Aluminum Enclosure.

- Split-body without flanges Extruded Aluminum Enclosure.

- One piece with flanges Extruded Aluminum Enclosure.

- One piece without flanges Extruded Aluminum Enclosure.

Each types of enclosure has various sizes to choose, an it can also custom according to your needs.

Custom Aluminum Enclosure Design

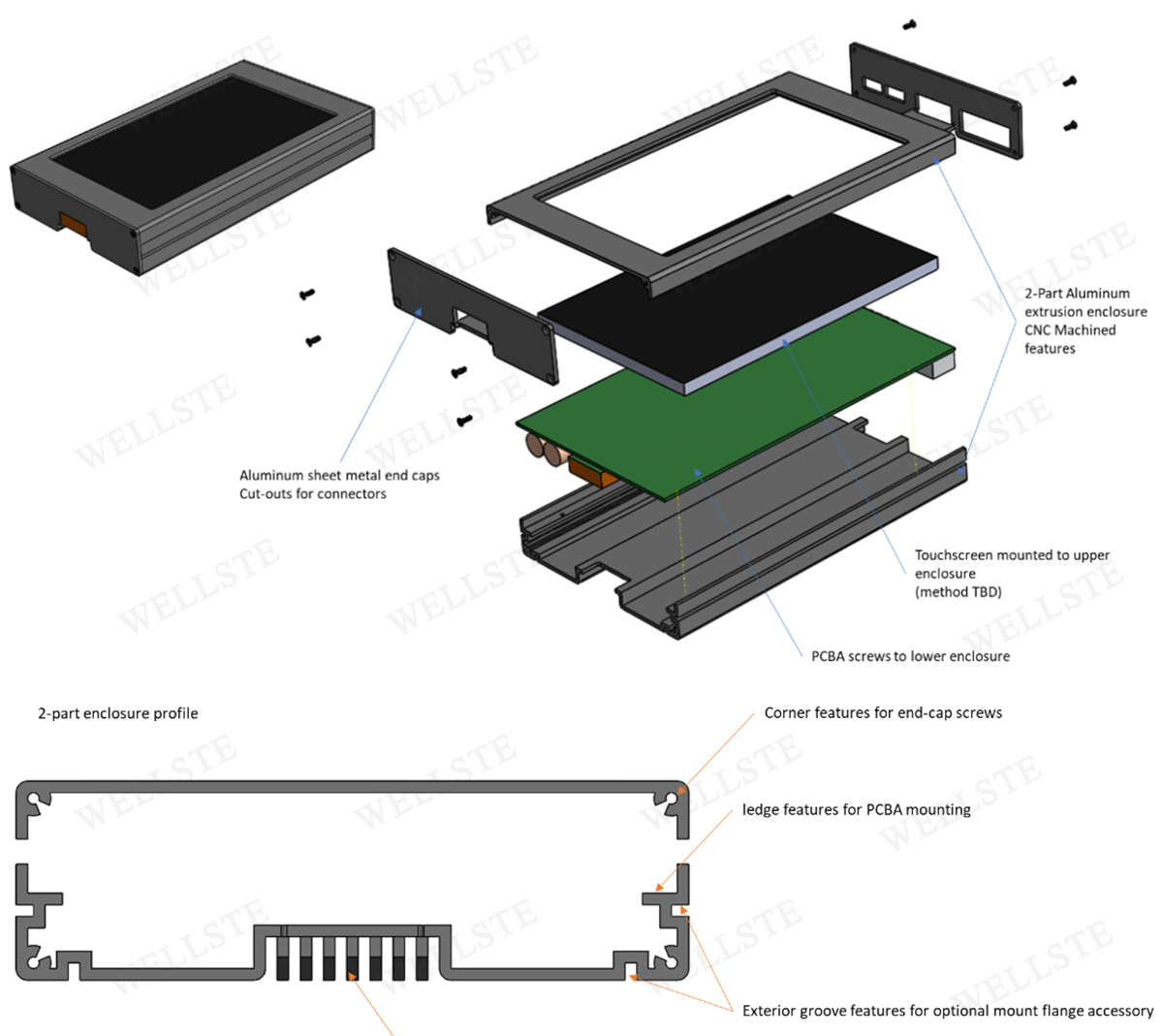

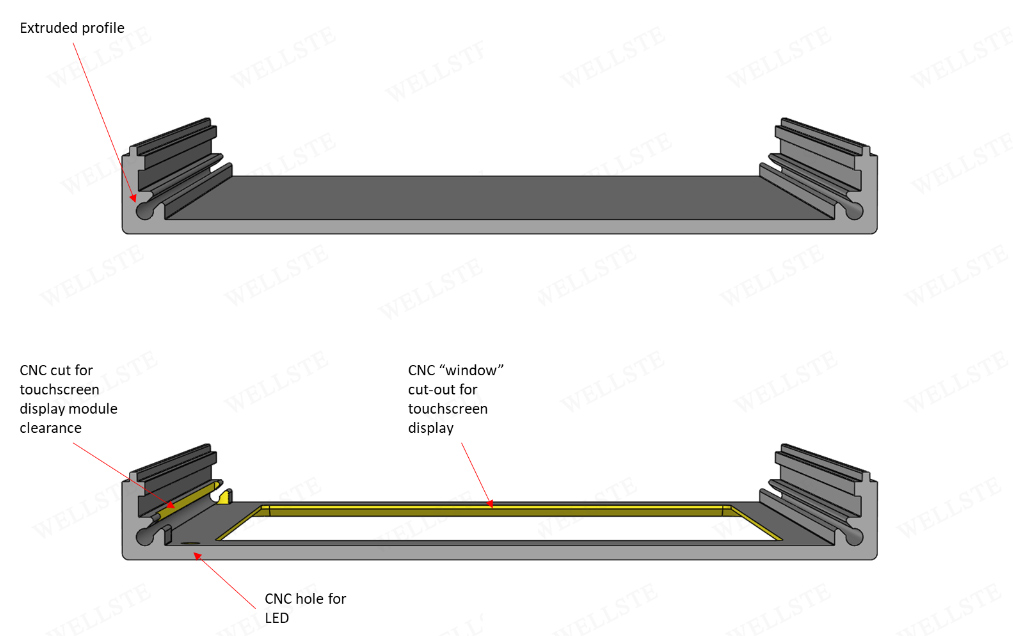

ABC choose a Custom Aluminum Enclosure for a 7″ touch screen device, the enclosure size is about 120x200x30mm, the PCBA needs to be screwed to the inner surface of theenclosure. ABC provided a concept drawing of their product design, and STP drawing.

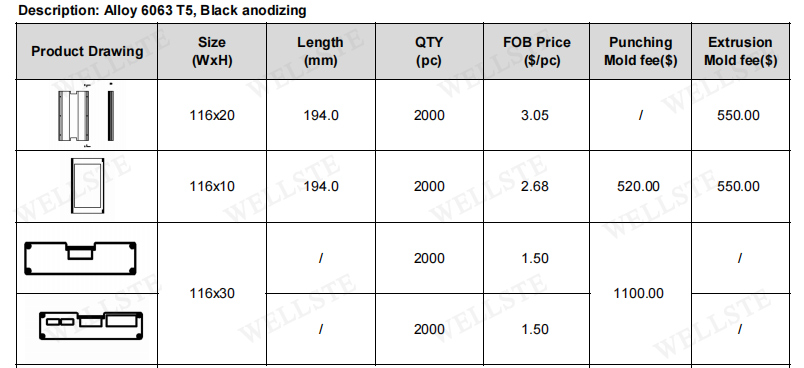

Preliminary quotation

Extruded Aluminum Enclosure price

On April 8, 2022, we gave a quotation to ABC after technical evaluation according to drawing provided by ABC, and ABC was satisfied with our price.

Can Wellste provide Extruded Aluminum Enclosure Sample?

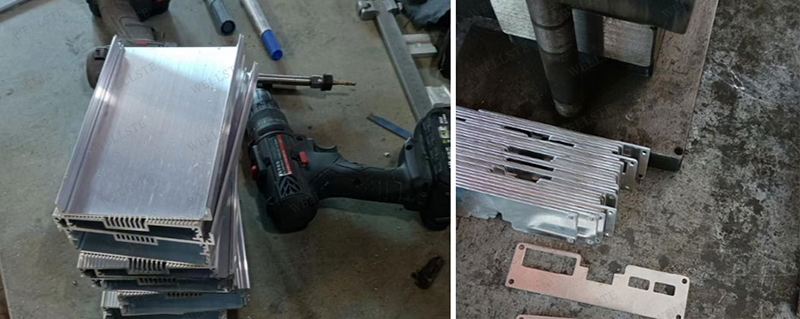

After the quote, ABC wanted to see if we had a Custom Aluminum Enclosure sample of similar size in stock to confirm the quality of our product. However, there was no sample of Split-body Extruded Aluminum Enclosure available, so we decided to produce and send a Anodized Aluminum Enclosure sample as shown in the picture to ABC to see the black anodizing surface and the quality of our products.

ABC was satisfied with our decision.

ABC received the sample from us and decided to choose us as the supplier.

Technical negotiations

How to design enclosure for PCB?

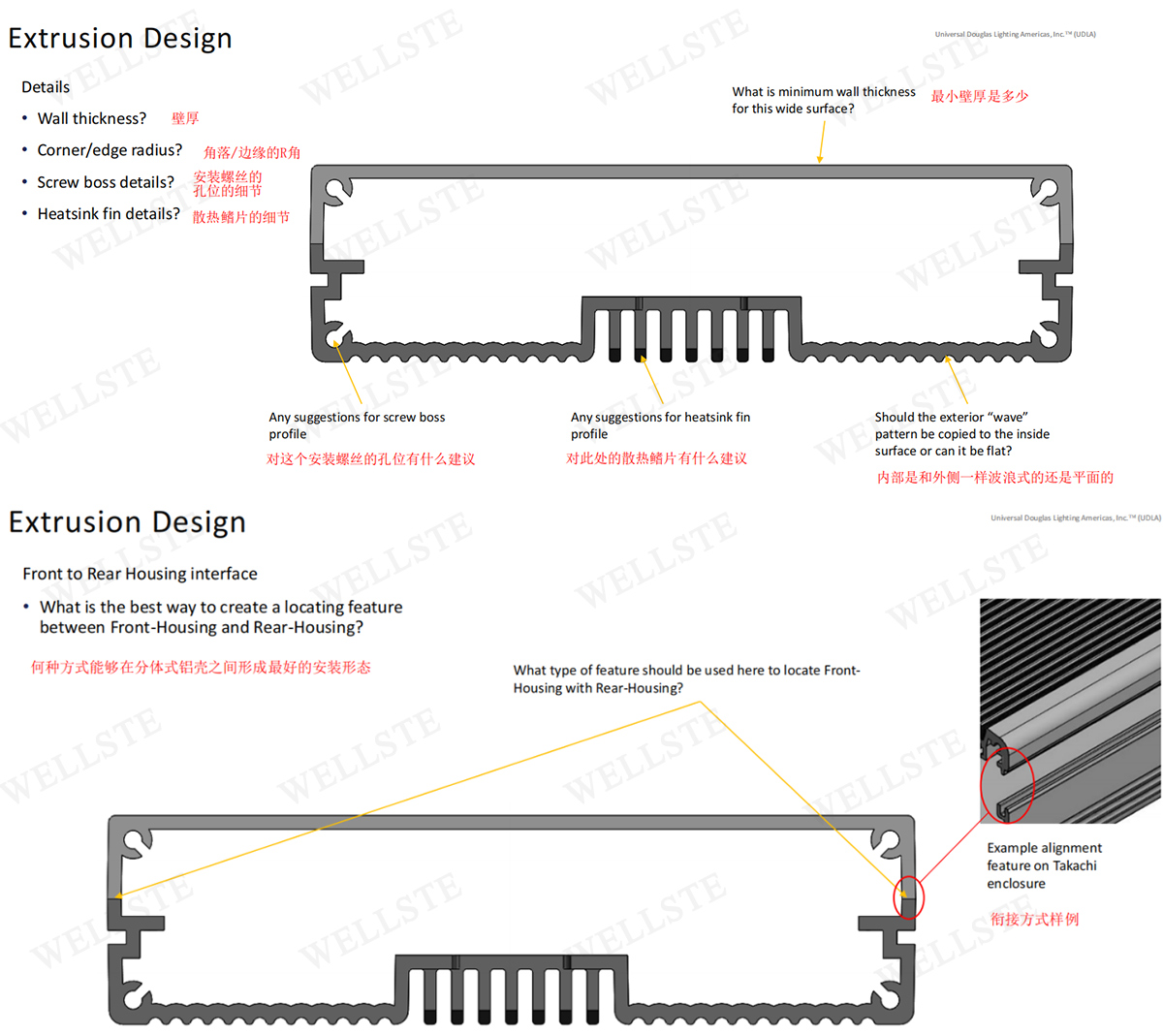

On 4/25/22, at which point the Custom Aluminum Enclosure samples were in production,ABC asked if we could offer some advice on his product and design, as well as our recommended wall thickness, heatsink size, allowable variations, etc.

There are many questions from customer, but it involves technical and production feasibility, and the processing of such products is difficult. We are willing to assist customers to make free attempts, because some problems can only be known after actual production whether some points can be achieved for Extruded Heat Sink Enclosure. Therefore, we still suggest to make a sample first and then make adjustments gradually.

How do we achieve such a large piece of window cutting?

One of the main concerns of ABC, in this profile, how do we achieve such a large piece of window cutting?

After a concentrated meeting of our engineers to evaluate, we suggested as below:

Because the opening is too large, if we use the CNC processing method, the fixture at both ends may lead to the deformation of the profile. It would be better to use the punching process to make this opening.

Aluminum Extrusion Clamp

Aluminum Punching

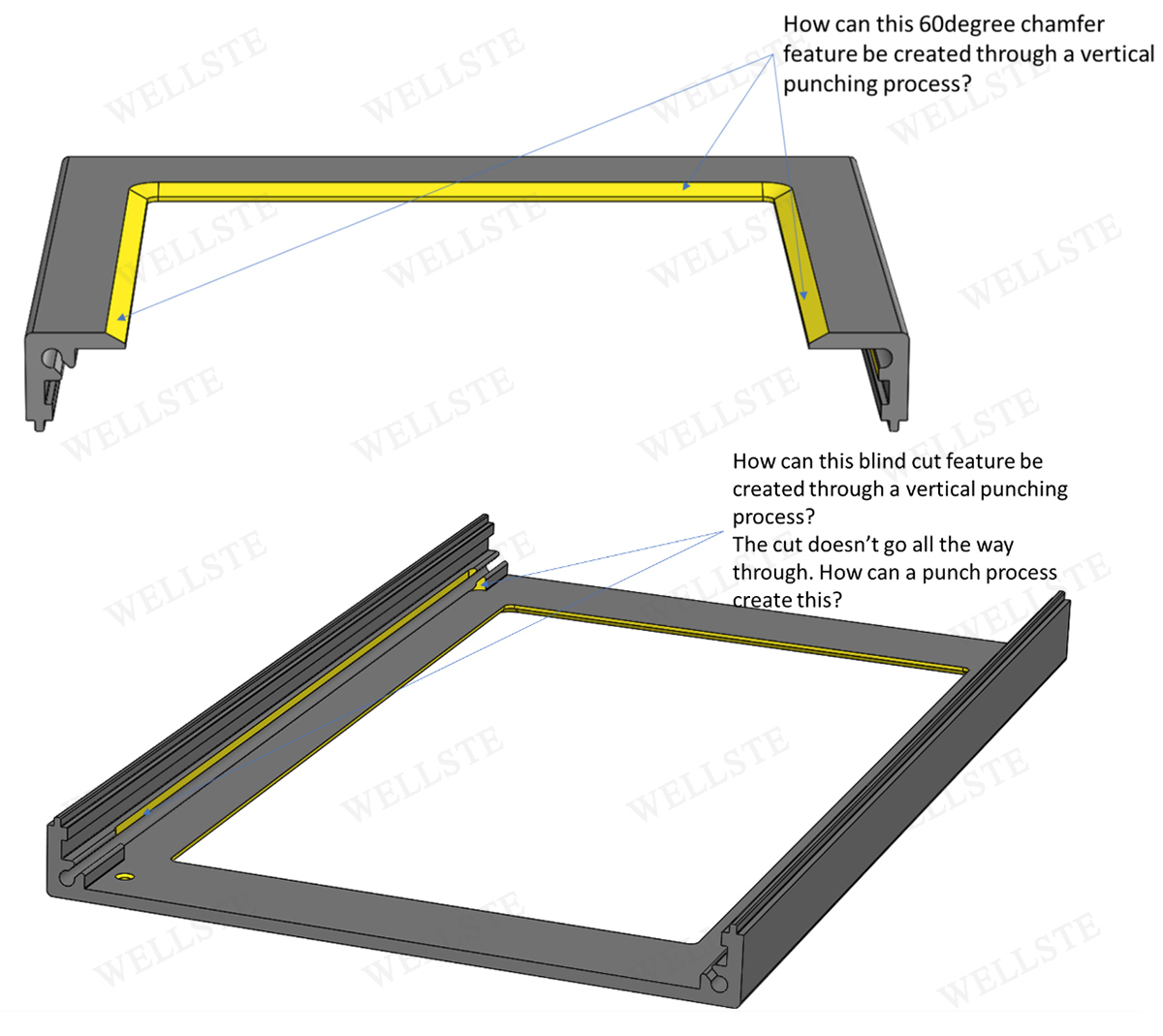

How to make the 60 degree chamfer around the opening?

ABC got the point, but at the same time another question arose – how to make the 60 degree chamfer around the opening?

Since the chamfer is for the LED display, ABC needs the chamfer to be clean and burr-free.

CNC Enclosure Design

In addition, since we are worried about the deformation caused by the fixture on both ends, how to CNC machine the small LED holes?

And what kind of process is used to make the notched part marked in the picture below?

Our engineers evaluated and gave the following production plan.

- first punch the large opening.

- and then CNC do chamfering.

During the chamfering process, the CNC fixture will not be too tight, so it will not lead to deformation, and the notched part is also milled off by CNC.

Extruded Aluminum Enclosure meeting discuss

After answering the questions, we invite ABC for a video meeting to see if they have more questions and we can solve them all together.

After the video meeting, ABC determined the final drawing and hoped our company could make a quick prototype. The order process is as follows.

- Production drawings are produced and ABC makes some more changes.

- ABC’s PCB design is not yet complete, so there may be some fine-tuning.

- Finalize the prototype drawing V5.

- We send the production drawing to ABC and get confirmation.

- Start the mold opening process.

Sample Production

On August 17, 2022, the Extruded Aluminum Enclosure Box and end plates samples are competed.

Problems encountered in production

Three solutions when the Extruded Aluminum Enclosure edges were damaged by the CNC tool

When making the Custom Aluminum Enclosuresample, the chamfer of the large window was too large and the Aluminum Enclosure was too light, it was easy to generate vibration during the actual CNC machining. Therefore the edges were damaged by the CNC tool.

Our company responded positively at the first time and gave ABC three solutions.

Option 1. If it is to ensure the smoothness of the edge, our staff can sand the edge by hand.

Option 2. If the chamfering is related to the later application, our engineers will re-evaluate and try to find other solutions.

Option 3. Is it acceptable to reduce the chamfer angle from 60 degrees to 45 degrees? And the depth of the chamfer needs to be reduced to 1mm or less. If so, we will try a new prototype immediately.

ABC responded that the purpose of chamfering was to provide a good transition between the housing and the touch screen that would be located in the window, increasing the user experience.

ABC agreed to change the angle and depth of the chamfer to make CNC machining easier.

On August 31, 2022, after changing the chamfer angle and depth, the chamfer was successfully machined.

On 29.9.2022, ABC received the sample and commented on the good quality. ABC is refining the Aluminum Extrusion Enclosure design to carry out subsequent production.

Some of the size and shape changes requested by ABC for the sample after receipt.

What must be included when designing an enclosure?

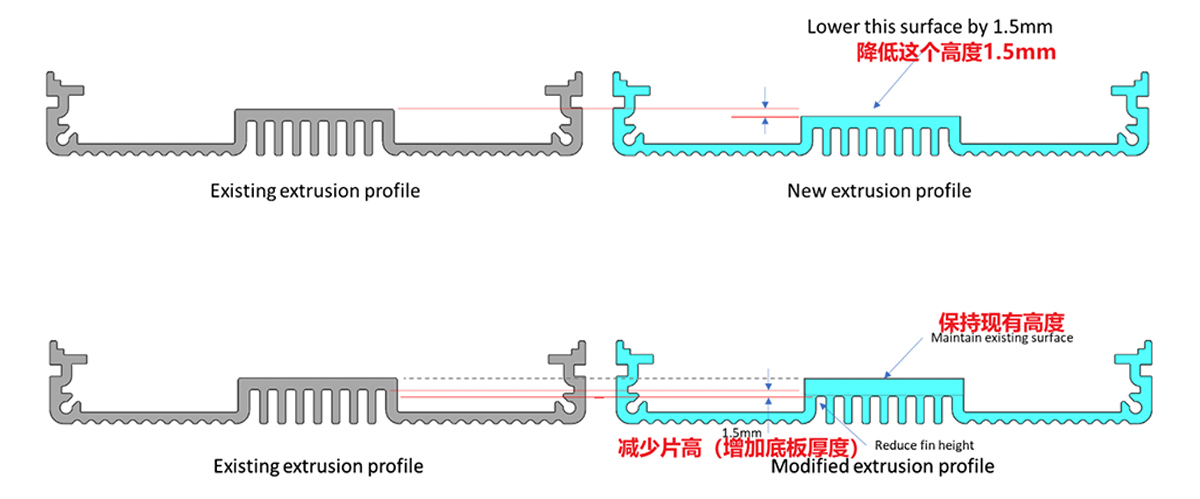

ABC is experiencing a problem with a component that may affect the shape/dimensions of the enclosure. Is it feasible if the change shown below must be made?

Our engineer replied that this shape could not be achieved by modifying the existing die, but only by opening a new extrusion die at the same cost of $550 as before.

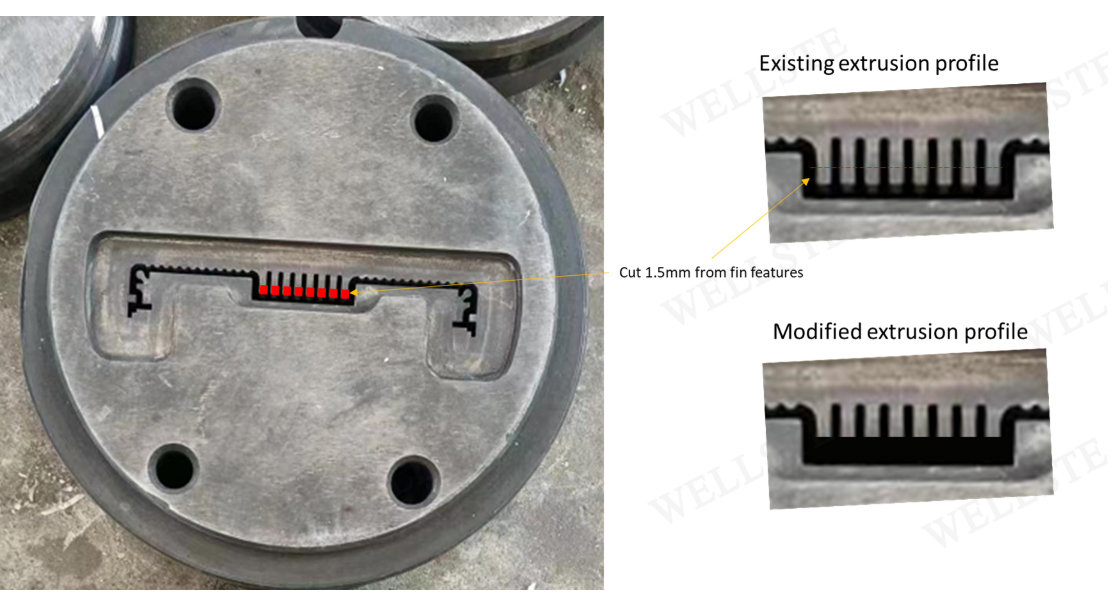

ABC did not want to open a new die, and the delivery time was long, so he proposed another modification as follows.

So we sent the current mold picture to ABC for reference, as follows

Our engineers evaluate that this change is feasible, and ABC will be responsible for part of the repair cost of $120.

Laser Printing for the Extruded Aluminum Enclosure

On December 2, 2022, ABC wanted to add their logo to the sample. Our company recommends laser engraving, which is beautiful and low-cost.

Aluminum Laser Marking

After professional and in-depth communication by our team, our company finally delivered the order successfully, and ABC indicated that it will enter mass production in 2023.