- Support big or small project and have NO MOQ

- Competitive price comparing to other suppliers

- Various capabilities of advanced CNC machine lines

- One to one technical engineers guide your design after inquiry

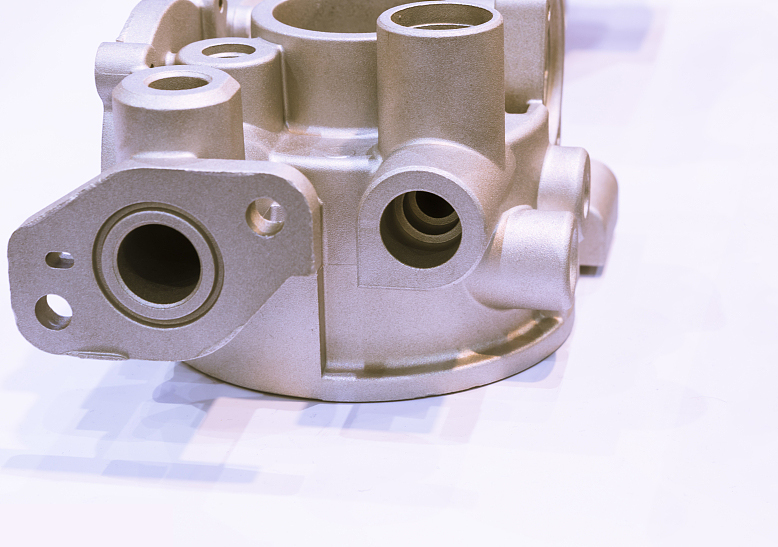

CNC Machining Aerospace Parts

CNC machining aerospace parts are made out of metal, plastic or other material. They are machined parts widely used in the aerospace applications.

CNC machining aerospace parts are the same as former parts and can take place of broken ones.

Aerospace companies used them to repair and assemble airplane framework.

Wellste: The Top CNC Machining Aerospace Parts Manufacturer

Wellste has a wide range of CNC machining aerospace parts, such as bolts, hinges and pistons. These common accessories are very important as inventory.

Wellste produces these CNC machining aerospace parts with good quality raw metal material from our reliable partners.

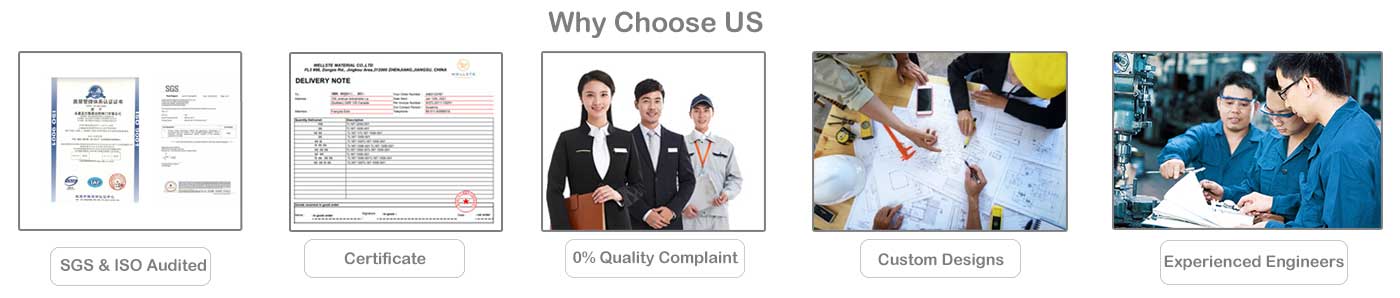

Wellste has been in CNC machining area for more than 10 years. We root in this area and only source best material for CNC machining aerospace parts.

In order to ensure high quality of these parts. They can also work steadily in later actual application without any error.

Wellste specialized technical engineers will start to taker over your case once they receive your inquiry.

We pay equal attention to every customer and offer machining services you need. Wellste engineering team does well in making evaluation based on CAD drawings, or other drawings with different formats.

Wellste engineers keeps improving and learning advance technology about CNC machining aerospace parts. Wellste is a ISO certificated company and sticks to aerospace industry standards.

We focus on high quality CNC machining aerospace parts as an outstanding aerospace manufacturer and keeps making them better and better.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

Products You May Looking for

Wellste: The Top CNC Machining Aerospace Parts Manufacturer

We are confident to produce CNC machining aerospace parts with any specified tolerance or dimension.

Wellste has the most advanced CNC machine lines, including 2/3 and 5-axis CNC machines and so on.

Other common CNC manufactures only can say no to your tight tolerance or complicated shape.

Wellste is here ready to share DFM with you and has more than 1 design improving options for your reference.

Wellste technical engineers are all patient enough to help you anytime you have difficulty proceeding with designing.

Wellste engineers confirm every design deals with you one by one.

In that case, we won’t make any mistakes in later production. To ensure 100% quality is Wellste purpose.

Aerospace industry is similar to medical industry in some ways, especially they all require extremely tight tolerance.

Aerospace manufacture parts need to work perfectly all the time. Any errors may lead to horrible result.

Tight tolerance and accuracy is sometimes more important than lead time and cost.

But Wellste succeed in guaranteeing both high quality and rapid delivery.

What’s more, our one-stop solution covers any requirements you may have.

We are capable to handle every machining methods or other secondary operation under one roof.

Wellste offer most economical production plan for you. You don’t have to pay extra fees for additional services like surface treatment or DFM guidance.

Wellste machining service include CNC milling,drilling and die casting.

Some precision CNC machining aerospace components are really thin and have large dimension.

Traditional producing method like extruding can not to deal with this kind of products. It has dimension limitation and products are easy to broke.

Their wall thickness are too think to be extruded, But CNC machines can solve this problem easily, CNC tools cut CNC machining aerospace parts directly from raw material.

These material can be metal and plastic. And Wellste engineers control this method by computer panels. Production machining processes don’t involve with human activity and make less errors.

Wellste is capable to handle every project regardless of quantity. We support one sample production for you in initial stage, we can also prepare high volumes production rapidly.

Wellste is willing to share manufacturing process with you.

Wellste QC system staffs check aerospace CNC machining parts frequently in manufacturing process.

As to these high precision parts, Wellste QC staffs have to inspect some samples. QC staffs use specialized equipment to measure CNC machining aerospace parts tolerance.

Wellste roots in the CNC machining industry and know well about importance to reach aerospace industry standards.

Aerospace companies will absolutely put tolerance and precision in first place.

Wellste customers can see the whole manufacturing process clearly and know what we will do for their project.

Wellste will prepare a detailed time schedule for production process in advance before final production.

Customers will also get videos or photos from Wellste technical engineers at any time during production.

Wellste offers tolerance or dimension report after production. Even if your product is only a very small valve or hinge. Wellste will send report in e-edition to you by email.

And we will also send original version to you directly by shipment. We aims at dealing with every case carefully and with satisfied service.

A prototype is very important for you, and Wellste support free samples after small batch production. Wellste will send them to you for further application test.

Wellste will only start bulk production after you approve our product quality.

Wellste will always be your most suitable and reliable supplier. We works with professional express company.

And our staffs are good at packaging, Wellste ensure delivery safety and speed.

What you cares most is what we can do perfectly for you. Wellste has advantages over other suppliers.

We invests in CNC machine lines frequently. Wellste has nearly all kinds of CNC machine lines for milling, cutting, drilling and turning and so on.

Wellste offers best product and price. We use machines like 5-axis CNC machines. They keeps working until we do regular maintenance or come to some small errors.

5-axis CNC machines operate a whole metal or plastic workpiece from 5 different directions with different tools. One 5-axis CNC machines can save budget for you.

In former traditional production, technical engineers have to move a workpiece from one lathe to another.

They have to adjust different CNC tools in order to complete complicated shape design.

It will cost a lot and add manual operating fees. Wellste keeps moving forward and introduces new technology to CNC machining aerospace parts production.

Wellste technical engineers will also work out economical design plan for you after evaluating your design drawings, Contact our sales team and get quote in 24hours.