- Low MOQ starts from 500KG only

- Temper O,T6, T6511, T3511, T76511

- Full quality inspection before shipment

- Hot extrude & Cold draw production technology

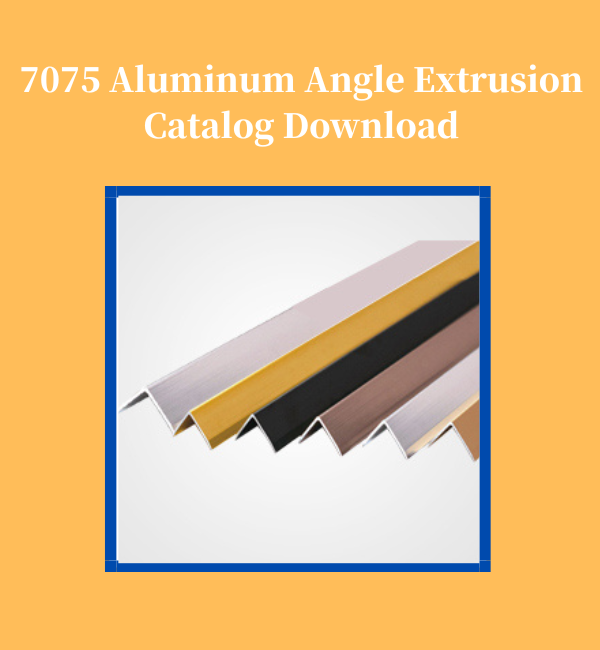

7075 Aluminum Angle Extrusion

Wellste 7075 aluminum angle extrusion has high strength properties but has an excellent balance between weight and strength ratio.

It strengthens under sub-zero temperatures and is the most used aluminum angle extrusion due to its long-lasting resistance to stress and corrosion.

Your Premier 7075 Aluminum Angle Extrusion Manufacturer

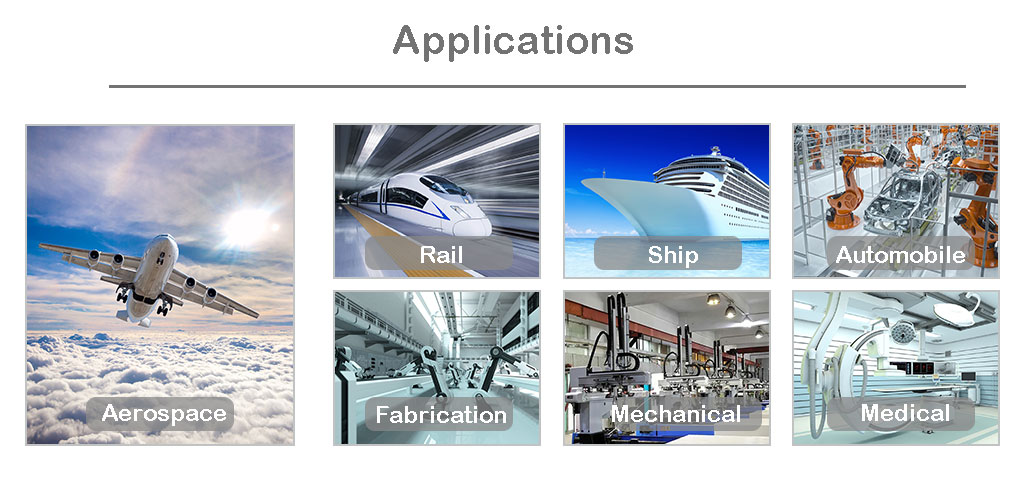

In demanding areas such as high-stress structural components or aircraft fittings, 7075 aluminum angle extrusion is popular in the aerospace industry.

This product is available in a range of forms and sizes, as well as aluminum angles for structural use.

Wellste is the leading industry on the market that offers customers a broad range of 7075 Aluminum Angle Extrusion at an affordable cost.

These angles are produced by the world’s leading market providers using top-notch material qualities.

Wellste 7075 aluminum angle extrusion offers superior features and properties, that make the product in industrial applications high level demanding.

In addition to the technical specifications, the 7075 extruded aluminum angle includes both global and domestic manufacturing requirements.

| Item Type | 7075 aluminum angle extrusion |

| Material | 7075, 6063,6061,5086,2024, etc. |

| Temper | T3-T8 |

| Shapes | Round, Rectangular, triangle, Customized Shapes. |

| Surface treatment | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| Deep processing | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication. |

| Standard | GB, ASTM , AISI , DIN , BS, JIS |

| Certification | ISO9001 |

| Delivery Time | 15-20 days after sample confirmed & down payment, or negotiated |

| OEM/ODM | Acceptable |

| Service | 1. Free sample, Free design; 2. OEM/ODM available; 3. Custom-made request; 4. New design solution suggestion. |

The needs and requirements of customers are considered when manufacturing 7075 extruded aluminum angles.

- Capabilities

- Workshop

- Package

-Standard Packing Option-

* Long bar length profiles 3.0-6.0 meters*

* Short bar length profiles 0.3-3.0 meters*

-Loading & Shipment-

We have a wide range of existing sizes in stock and we don’t have MOQ for products in stock.

Yes, we also have extra CNC machining service for you, it is all up to your project.

Yes, we support samples for your quality approval in the initial stage for further cooperation.

It’s based on the value of your goods, if your good value is under USD 5000, our payment term is 100% T/T in advance.

Yes, we cooperate with customers all around the world.

Usually, we produce the 6063 and 7075 aluminum angle.

Related Products

Wellste aluminum boat extrusions are mostly made from marine-grade aluminum alloy. They are all anti-corrosion even in marine applications under near seashore. Marine grade aluminum alloy is light and saves fuel for you when sailing. It is the most economical option for your project.

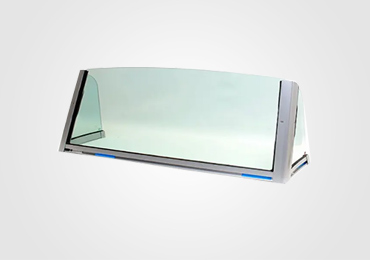

Wellste boat windshield frame extrusions support free design service based on your size information. We only use high-quality marine grade aluminum alloy like 5058 and so on. They are suitable for your own boat or high-end customization. Our engineers will also offer good after-sales service.

Wellste marine aluminum extrusion is created by outstanding raw materials from our reliable partners. We support anodizing services and are capable to add anodizing film thickness to even 15 μm. It expands aluminum extrusion lifespan to at least 10 years or more.

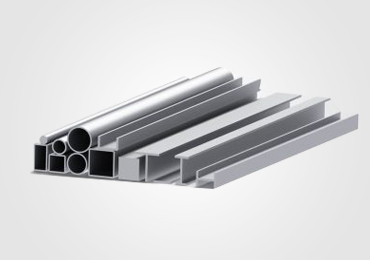

Wellste 2024 aluminum extrusion serves many companies all around the world in the aerospace area. 2024 grade tensile yield strength is 324 MPa. It is far stronger than many other aluminum alloys. And it mainly consists of copper which makes it extremely strong.

Wellste 5086 aluminum pipe is a high-strength alloyed aluminum product, it is good for aerospace or marine application because of its outstanding corrosion resistance. It can work as usual even under salty seawater. Wellste ensures fast delivery with a detailed schedule.

Wellste aerospace aluminum extrusion is lightweight and rigid enough to undertake high-pressure work as aerospace components. It has good quality with high precision and tight tolerance, it can save extra maintenance fees for you because it is durable and won’t break.

Wellste offers satisfied customization services for your anodized aluminum angle project. Our professional engineers are always at your service. They suggest similar existing sizes for your reference first and if they are not acceptable, engineers also guide your design.

Wellste 7075 aluminum tube has excellent strength and it protects the tube from cracking. Thanks to its good stress-corrosion cracking resistance,7075 aluminum is widely used in the aerospace industry. Wellste supports free quality reports for you after production.

Wellste polished aluminum angle is in compliance with national standards and reaches high precision. We have all kinds of polished aluminum angles with different dimensions or sizes. We offer the most economical product and will give a quick quotation within one day.

Wellste: Your Leading 7075 Aluminum Angle Extrusion Manufacturer

Wellste 7075 aluminum angle extrusion provides a decent strength to weight ratio and moderate durability of products. At lower zero temperatures it gets even stronger and harder due to its stress corrosion resistance, which makes this material into consideration.

Wellste 7075 aluminum angle extrusion is used in many particular industrial applications. Customers are provided with various shapes and sizes, including structural angles. The angles produced with this alloy have various characteristics such as corrosion resistance, high tensile strength, formability, and workability.

7075 aluminum angle extrusions are well inspected, and tests are conducted by our experts when talking about quality. Wellste quality assurance workers ensure that all tests are carried out at various temperatures and at different pressures to recognize the performance and quality of these angles.

Wellste 7075 aluminum angle extrusion is examined including third-party inspection, hardness testing, pitting resistance, durability testing, visual inspection, and positive identification of the material.

The whole testing process are carried out following industry standards under the regulation of experts.

Finally, the aluminum alloy 7075 is packed in boxes/cartons of wood or upon your demand.

Wellste 7075 aluminum angle extrusion has good post-solution plasticity and has an excellent thermal enhancement effect. It has high strength under 150 degrees, and it has helpful low-temperature resistance, stress corrosion cracking, poor weldability, and double aging can improve the performance of anti-SCC.

Wellste 7075 aluminum angle extrusion has less corrosion resistance than many other aluminum alloys but is much better corrosive than the 2xxx alloys (2024, 2A12). Its relatively costly application is limited and its extrusion in production compared to other aluminum alloys is also harder. Aerospace profiles vary slightly according to the thickness of walls, in contrast to a bar and plate.

Wellste stocks 7075 aluminum angle extrusions for regular size, we ensure fast shipment with stock items, we also have a long-terms partner to ensure stock products more various and widely, not only equal or unequal aluminum angle legs bar, but also other special alloys no about aircraft aluminum extrusion, your initial business cost will decrease a lot to work with Wellste.

Wellste warmly welcomes to contact our sales engineer to get the latest quotation, we are online 7X24H fast response your answers.

7075 Aluminium Angle Extrusion: The Ultimate FAQ Guide

If you have any question about triangular aluminium angle extrusion, you will find the answer right here.

So, if you want to be an expert in triangular angle extrusion, read this guide.

- What is 7075 Aluminium Angle Extrusion?

- What are the Mechanical Features of 7075 Aluminium Angle Extrusion?

- How does 7075 Aluminium Angle Extrusion compare to 7075 Aluminium Channel?

- What are the Physical Features of 7075 Aluminium Angle Extrusion?

- Which Types of 7075 Aluminium Angle Extrusion Processes are there?

- How do you Manufacture 7075 Aluminium Angle Extrusion?

- What are the Uses of 7075 Aluminium Angle Extrusion?

- What are the Benefits of 7075 Aluminium Angle Extrusion?

- Is there Recommended Thickness for 7075 Aluminium Angle Extrusion?

- How do you Test the Quality of 7075 Aluminium Angle Extrusion?

- What Determines the Cost of 7075 Aluminium Angle Extrusion?

- What is your Turnaround Time for Manufacturing 7075 Aluminium Angle Extrusion?

- What is your MOQ for 7075 Aluminium Angle Extrusion?

- Can you Customize 7075 Aluminium Angle Extrusion?

- What are the available Sizes of 7075 Aluminium Angle Extrusion?

- Are there Limitations of 7075 Aluminium Angle Extrusion?

- Can you Heat Treat 7075 Aluminium Angle Extrusion?

- Are there Recommended Quality Certifications for 7075 Aluminium Angle Extrusion Manufacturers in China?

- What is the Chemical Composition of 7075 Aluminium Angle Extrusion?

- What can Cause Failure of 7075 Aluminium Angle Extrusion?

- What are the Available Surface Finishes for 7075 Aluminium Angle Extrusion?

- How do you Specify 7075 Aluminium Angle Extrusion?

- How long will 7075 Aluminium Angle Extrusion Last?

- Is there Aluminum Alloy that can Replace 7075 Aluminium Angle Extrusion?

- What are the Thermal Properties of 7075 Aluminium Angle Extrusion?

- How does 7075 Aluminium Angle Extrusion compare to Steel Angle Extrusions?

- What Causes 7075 Aluminium Angle Extrusion to Crack?

What is 7075 Aluminium Angle Extrusion?

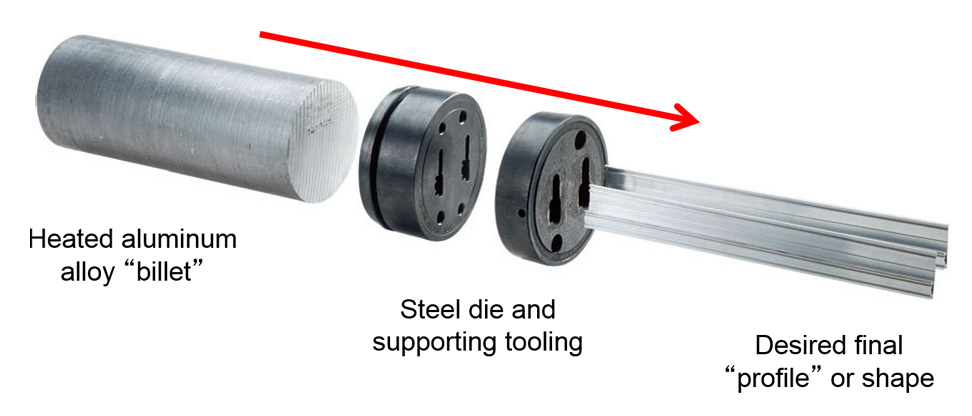

7075 Aluminium Angle Extrusion process formed by forcing aluminium alloy through a die with a set unique cross-sectional shape. 7075 aluminum angle extrusion features high-strength properties.

Still, it has a very good balance between the weight and strength ratio.

7075 Aluminum Angle Extrusion

What are the Mechanical Features of 7075 Aluminium Angle Extrusion?

7075 Aluminium Angle Extrusion is the most popular aluminum alloy. This is because of its superior mechanical properties that consist of overall high tensile strength and increased hardness.

Tensile strength is categorized into three groups which include:

- Ultimate Tensile Strength

- Yield Tensile Strength, and

- Elongation Tensile Strength.

The T6 temper of 7075 Aluminium Angle Extrusion has an Ultimate tensile strength of 83 KSI. Similarly, it features a Yield Tensile Strength of 73 KSI and Elongation Tensile Strength of 11%. Moreover, its hardness according to the Brinell scale is 150.

Also, the T7 temper of 7075 Aluminium Angle Extrusion has an Ultimate tensile strength of 73 KSI. Likewise, it has a Yield Tensile Strength of 63 KSI and Elongation Tensile Strength of 13%.

How does 7075 Aluminium Angle Extrusion compare to 7075 Aluminium Channel?

With 7075 Aluminium Angle Extrusion, the aluminum is forced out of the die opening.

The die has been selected, and the extruded aluminium takes the shapes of the die openings.

In the 7075 Aluminium Channel, the aluminum passes through a channel; an example is the flow channel.

It comprises a flow channel that is separated into four geometrical areas, a binding bar, and the die.

The aluminum alloy flows through the channel that has parameters that can be manipulated to ensure uniformity.

What are the Physical Features of 7075 Aluminium Angle Extrusion?

The following are the common physical properties of 7075 aluminium angle extrusion;

- Heat resistant

- Precisely designed

- High strength

- Malleable

- Corrosion-resistant

- Durable

Which Types of 7075 Aluminium Angle Extrusion Processes are there?

There are four types of 7075 Aluminium Angle Extrusions that consist of:

Direct Aluminum Angle Extrusion

The direct process involves the billet, the ram as well as the punch all working in the same direction.

Indirect Aluminum Angle Extrusion

With indirect process, the billet and the punch working in opposite directions.

Impact Aluminium Angle Extrusion

In the impact process, the impact load causes the punch to hit the slug at an increased speed.

Hydrostatic Aluminum Angle Extrusion

The hydrostatic process involves pressure being transmitted to the billet through the fluid, which is filled into a container.

How do you Manufacture 7075 Aluminium Angle Extrusion?

Here are the steps in the process of manufacturing 7075 aluminum angle extrusion:

Step One

This is where the extrusion die is designed and relocated to the extrusion press. It is essential for the die to be preheated at a temperature range of 450-500 degrees Celsius.

The preheating assists in improving the die’s life and guarantee an even metal flow.

Aluminum angle extrusion process

Step Two

Here, a block of an aluminum alloy commonly referred to as a billet is separated from an elongated log of aluminum alloy.

It is preheated in an oven at 400 to 500 degrees Celsius, which enhances malleability.

Step Three

The billet is transferred mechanically to the extrusion press, and a lubricant is put on it. The lubrication helps to prevent it and the extrusion ram from sticking on each other.

Step Four

The ram forces the billet material into the repository. At this point, the ram then exerts a pressure of up to 15000 tons to the malleable billet.

The ram forces the billet material into the repository of the extrusion press. The aluminum then enlarges to fill the container.

Step Five

As the aluminum alloy fills the repository, it gets pushed up against the Extrusion die. Consistent pressure is maintained, forcing the aluminum through the openings in the die.

Step Six

Extrusion is held by a puller, which leads it along with the run-out surface at uniform speed as it exits from the press.

As it progresses along, it is evenly cooled by fans or a water bath.

Step Seven

Extrusions are trimmed to the length of the table. This is done using a hot saw to remove it from the continuing extrusion process

Step Eight

the heated extrusions are physically transferred to the cooling table to lose heat up to room temperature.

Step Nine

The 7075 Aluminium Angle extrusions are then relocated to the stretcher and straightened. This extrusion process involves twisting, which occurs naturally, and therefore requires realignment.

Step Ten

Extrusions are moved to the additional process where they are finished, sawed, and cut to length depending on the client’s or standard specification.

What are the Uses of 7075 Aluminium Angle Extrusion?

The applications of 7075 aluminum angle extrusion include;

- Making rails

- Used for structural or architectural applications

- Making frames

- Used to make automotive components

- Domestic and office furniture

- Furniture applications

What are the Benefits of 7075 Aluminium Angle Extrusion?

The 7075 aluminium has high strength. Its level of resistance to stress and stress makes it highly useful in aerospace.

In addition, it provides a visually appealing finish when polished. It consists of 90% aluminum 5.6% zinc, 2.5% magnesium and 1.6% copper.

This is in addition to a combination of a density of 102 lbs/cubic inch. Therefore, it can support high flight altitudes.

Is there Recommended Thickness for 7075 Aluminium Angle Extrusion?

There is no standard thickness for 7075 Aluminium Angle Extrusion. The thickness varies depending on several factors.

Some of the factors taken into account include the shape, size, and type of 7075 Aluminium Angle extrusion.

For 7075-T6, 7075-T65, and 7075 O, the minimum thickness should be equal to or less than 25.00mm. Similarly, the maximum thickness should be less than or equal to 200.00mm.

You realize that the minimum thickness differs in every category. For that matter, there is no specified thickness.

Knowing the type and function of the extruded aluminum helps determine the minimum thickness required. It also helps you understand how much it is acceptable for you to deviate from the specified minimum thickness.

How do you Test the Quality of 7075 Aluminium Angle Extrusion?

There are several tests done to ascertain the quality of the 7075 extruded aluminium including:

a) Visual Tests

Defects Check

Inspecting the material for defects is essential. Any defect on the extruded aluminum is an indication of low quality.

Some of the defects to look out for include:

- Dark specks

- Cracking

- Ines on the surface

- Warps

- Wall thickness that is not uniform

- Lumps, and

- Uneven coatings among other defects.

b) Colour Test

This is carried out by comparing the product to the Pantone color chart. It can also be compared to already approved samples.

c) Dimension Tests

The dimensions should be done according to the set standards. The thickness, height, shapes, size are some of the important dimensions, and your extruded aluminium should comply with the set standards.

d) Finishing Check

The finishing should be glossy, smooth, evenly coated.

e) Weight Test

The extruded aluminium should adhere to the set standards.

f) Extrusion Performance Test

Tensile Test

The tensile test is done using a universal machine. The tensile strength of the 7075 Aluminum Angle Extrusion is compared to the set standard.

It is essential for the extruded aluminum bar to adhere to the set standards, neither exceeding nor receding past the set values.

Corrosion Resistance

The product should experience a minimal amount of corrosion. There are specified standards set indication how much corrosion is acceptable above which the metal becomes compromised.

Hardness Test

The hardness of the extruded aluminum can be tested in several ways. First, the hardness of the extruded aluminium is an indication of the metal’s stability, and it is therefore essential.

Chemical Resistance

This test is done to check the extruded aluminium resistance against specific chemicals. These chemicals include muriatic, nitric acid, mortar, window cleaner, and detergent.

Weathering Resistance Testing

This test is carried to determine its viability and its level of resistance to harsh environmental conditions.

Abrasion test

This test is done to test the extruded aluminum’s resistance to mechanical wear.

What Determines the Cost of 7075 Aluminium Angle Extrusion?

7075 Aluminium Alloy Angle Extrusion

Several factors determine the cost of 7075 Aluminium Angle Extrusion. These factors include:

- The price of the raw materials for 7075 Aluminium Angle Extrusion.

- The size of the 7075 Aluminium Angle Extrusion.

- Heat treatment of the 7075 Aluminium Angle Extrusion.

- The cost of the Extrusion die.

What is your Turnaround Time for Manufacturing 7075 Aluminium Angle Extrusion?

Normally, the turnaround time for Manufacturing 7075 Aluminium Angle Extrusion varies by a significant amount of time.

The extrusion process itself does not take along, it usually takes a few hours maximum.

Besides, the amount of time depends on the size of the extruded aluminum wanted.

The aluminum is then artificially aged, which takes up to 12 hours.

After cooling, it is packaged and forwarded to the next stage. This process takes an average of 48 hours.

The next stage involves fabrications, finishing, cutting, among others, depending on the client’s specifications. The process could take up to two weeks each.

Therefore, the time depends on the design, size, and additional requests of the clients.

The currently specified turnaround time for specialized products in the market are;

- 50-60 weeks for drawn seamless aluminum tubing

- 25-30 weeks for structural extrusions in alloys

- 12-14 weeks for drawn porthole tubing

What is your MOQ for 7075 Aluminium Angle Extrusion?

Our MOQ is based depend on the weight of the 7075 aluminum angle extrusion you need.

But we can guarantee you – we have flexible MOQ, just contact our team.

Can you Customize 7075 Aluminium Angle Extrusion?

Yes, it is possible to customize 7075 Aluminium Angle Extrusion. Customization ensures that the product is manufactured according to your needs.

Standard7075 Aluminium Angle Extrusion is sometimes cheaper. But you will incur additional costs if you decide to use your specifications of the 7075 Aluminium Angle Extrusion.

Custom 7075 Aluminium Angle Extrusion initial cost is high. However, it is a guarantee that you will have it manufactured to suit your needs.

What are the available Sizes of 7075 Aluminium Angle Extrusion?

There are different sizes available. Conducting market research will allow you to develop a size range that will best suit your needs.

The 7075 Aluminium Angle Extrusion can also be custom made if your requirement is outside the available size. The size is therefore entirely up to you.

Are there Limitations of 7075 Aluminium Angle Extrusion?

The 7075 Aluminium Angle Extrusion is very expensive and can be challenging for most people with financial constraints.

It is harder to treat the surface of the 7075 Aluminium Angle Extrusion compared to other aluminum alloys.

It is less resistant to corrosion than other aluminum alloys as it contains copper. This makes it more robust but vulnerable to harsh environments.

Furthermore, it is challenging to wield and form 7075 Aluminium Angle Extrusion.

Can you Heat Treat 7075 Aluminium Angle Extrusion?

Heat treatment of 7075 Aluminium Angle Extrusion is done to improve the metal tensile strength and yield strength.

The heating takes place in the aging ovens, where they undergo artificial aging.

It is heated for a minimum of twelve hours up to twenty-four hours for temperatures of about 350°F to 500°F.

This process increases the strength and durability of the 7075 Aluminium Angle Extrusion. In addition, the process brings the metal up to a T6 temper.

Are there Recommended Quality Certifications for 7075 Aluminium Angle Extrusion Manufacturers in China?

There are several safety and quality certifications and standards for 7075 Aluminium Angle Extrusion which include:

- ISO 9001:2015: Ensures that there is a quality management system for the entire manufacturing process. The processes covered includes fabrication, Extrusion, finishing, and casting of the 7075 Aluminium Angle Extrusion.

- ISO 14001:2015: Ensures that there is an adherence to sustainable and quality environmental management. It covers the manufacture of pipe fittings, flanges, fasteners, welded as seamless, and any different additional process in 7075 Aluminium Angle Extrusion.

- ISO 45001:2018: The certification makes sure that the work adheres to the set requirements for occupational health and safety management system.

- PED Certification: The Pressure Equipment Directive is by the European Union. It provides the requirements for the design, installation, fabrication, and usage of pressure equipment.

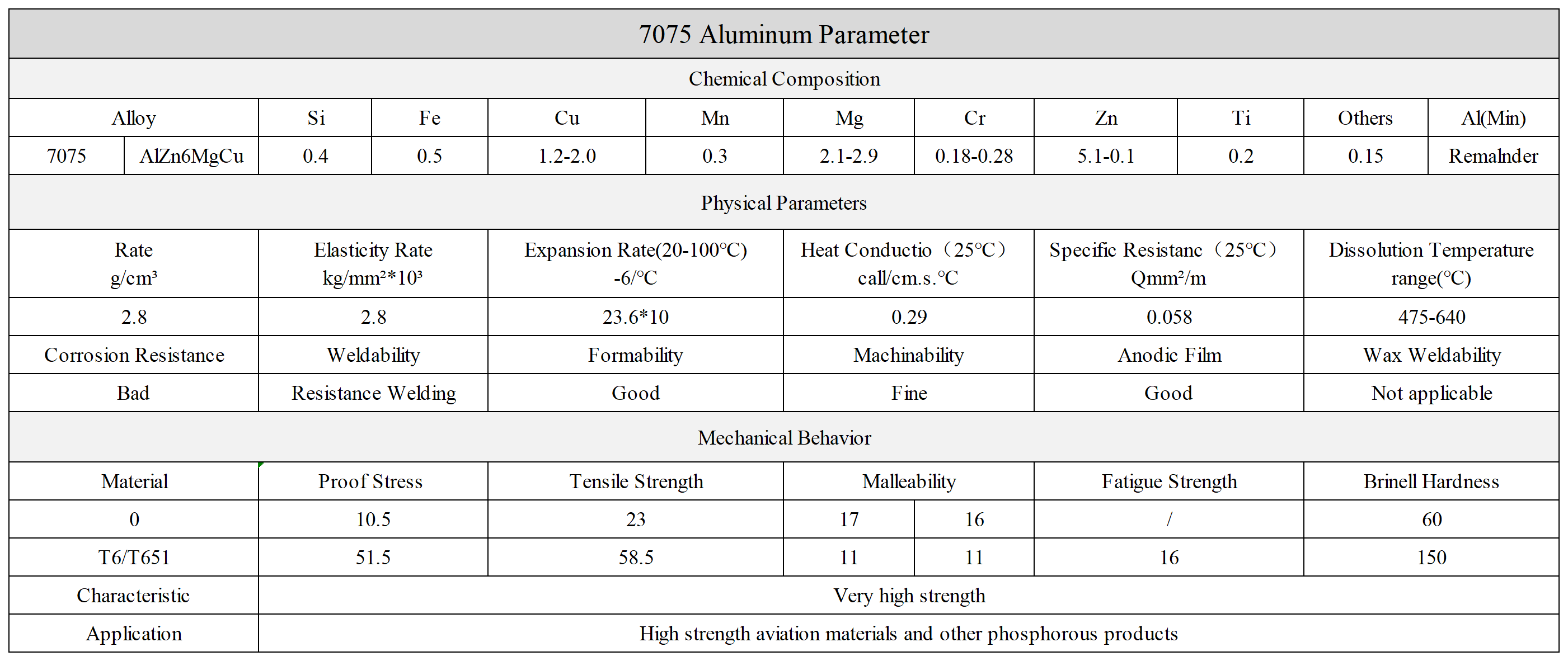

What is the Chemical Composition of 7075 Aluminium Angle Extrusion?

The chemical composition of 7075 Aluminium Angle Extrusion is as follows:

- 6–6.1% of Zinc

- 1–2.5% of magnesium

- 2–1.6% of copper

- 4% of Silicon

- 5% of Iron

- 3% of Manganese

- 2% of Titanium

- 18% – 0.28% of Chromium and other metals.

These figures could, however, slightly vary in different 7075 Aluminium Angle Extrusion.

What can Cause Failure of 7075 Aluminium Angle Extrusion?

The 7075 aluminum angle extrusion produces the strongest aluminum alloys currently available.

Its tensile strength and great mechanical properties make it the leading aluminum alloy in the market.

However, it is less resistant to corrosion than other aluminum alloys as it contains copper. It is the copper component that makes it stronger and vulnerable to the harsh environment.

Copper is necessary for increasing its strength. Yet, it is the most common cause of failure of 7075 Aluminium Angle Extrusion by increasing its corrosion levels.

7075 Aluminium Angle Extrusion

What are the Available Surface Finishes for 7075 Aluminium Angle Extrusion?

There are different types of finishing for 7075 Aluminium Angle Extrusion, which comprise of:

Pre-treatment

The finish involves first cleaning the material surfaces with either a basic or acidic solution then proceed to coat the surface.

Pre-treatment is done to increase adherence of the coating material to the surface and reduce corrosion.

Anodizing

This is an electrochemical procedure that adds protection on the surface of the 7075 Aluminium Angle Extrusion.

The Extra protection is in the form of a porous anodic oxide layer

Mechanical Finishing

The finishing involves processes like buffing, blasting, polishing, grinding, or sanding of the extruded aluminium to improve its quality and overall appearance.

Liquid Paint

This finishing process involves applying a film of liquid paint on the extruded aluminium.

Powder Coating

It involves the application of a solid film on the surface of the extruded aluminum.

Bright Dipping

This process involves dipping the extruded aluminium into a solution. The solution is made up of heated phosphoric and nitric acids. It gives the metal a bright mirror-like finish.

How do you Specify 7075 Aluminium Angle Extrusion?

7075 Aluminium Angle Extrusion is specified in terms of length, width, thickness, angle, size, among other things.

In addition, temper, surface, and finish can also be used to specify 7075 Aluminium Angle Extrusion.

How long will 7075 Aluminium Angle Extrusion Last?

7075 Aluminium Angle Extrusion can last for a very long time.

Extruded aluminum is taken through an artificial aging process to further harden it, using age-hardening as an added advantage.

Therefore, 7075 Aluminium Angle Extrusion lasts for a very long period.

Is there Aluminum Alloy that can Replace 7075 Aluminium Angle Extrusion?

Among the aluminum alloys present, 7075 Aluminium is the best one so far because of its superior physical properties including:

- Heat Resistance

- Unique Designs

- High Strength

- Malleability

- Corrosion-Resistant, And

- High Durability

However, it has less corrosion resistance compared to other aluminum alloys. This is because it has copper, which makes it stronger but also vulnerable to the harsh environment.

It is also more expensive and therefore has limited uses as most people prefer cheaper, more economically feasible alternatives. Cracking is another disadvantage mainly caused by corrosion.

Aluminum lithium ( Al-Li) has been proposed as an alternative to replacing previous aluminum alloys. Lithium is known to be significantly less dense compared to other metals.

Therefore Al-Li is lighter than other aluminum alloys, including 7075 Aluminium Angle Extrusion, giving a weight deficit of up to 10%. Because of their decreased weight, they have applications in aerospace, which leads to better fuel efficiency.

Third generation Al-Li have a lesser percentage of lithium which helps in combating negative effects like fracture toughness and less strength. They do so while employing advantages such as thick structure, increased strength plate, and extrusions for wings

What are the Thermal Properties of 7075 Aluminium Angle Extrusion?

7075 Aluminium Angle Extrusion has the following thermal properties:

- Thermal conductivity (k) of 7075 Aluminium is 196 W/m*K.

- Melting temperature (Tm) of 7075 Aluminium is 477 °C or 891 °F. This number is not fixed and can change with different 7075 aluminum.

- Specific heat capacity (c) of 7075 Aluminium is 714.8 J/kg*K.

- Linear thermal expansion coefficient (α) of 7075 Aluminium is 2.36*10-5 K-1. Thermal expansion is disposition of matter to alter its properties, such as shape, volume, area, and density in reaction to difference in temperature.

How does 7075 Aluminium Angle Extrusion compare to Steel Angle Extrusions?

7075 Aluminium Angle Extrusion and Steel Angle Extrusions are the two most sought-after extruded metals.

They both have superior mechanical properties that make them the best in the market.

They differ in the following ways:

The market price for 7075 Aluminium is higher than the steel counterpart. This is because the raw materials used in the production of 7075 are more expensive, which in turn increases the selling price.

7075 aluminum Angle extrusion has more corrosion resistance compared to steel.

This makes it more preferable in wet areas and in areas where there are harsh environmental conditions.

Moreover, 7075 aluminum is very reliable, which makes it easier to produce a more intricate design. However, this also means that it is generally weaker compared to steel.

Aluminium 7075 Angle Extrusion

Steel angle extrusion designing is limited as it is very resilient and strong. Therefore, it is more resistant to being shaped, limiting the design options, hence its applications.

Furthermore, 7075 aluminum is preferable in terms of weight as it’s lighter than steel.

Steel is denser meaning it offers more in terms of strength. Nonetheless, this feature makes it heavier, which is why 7075 Aluminium is preferred for aerospace applications.

What Causes 7075 Aluminium Angle Extrusion to Crack?

Some of the primary chemicals of 7075 aluminum angle extrusion such as copper, Silicon, Zinc, and magnesium are soluble.

Unfortunately, their solubility makes them vulnerable to cracking caused by stress corrosion.

When it is exposed to a moist environment that contains moisture and any liquid, including liquid metal, the corrosion process is initiated.

If it is exposed to stress at the same time, stress corrosion cracking occurs, normally happening at the grain boundaries.

For all your 7075 aluminum angle extrusions from China, you can contact Wellste now.