Laser Welding vs TIG Welding: Which Is Better for Aluminum Fabrication?

Aluminum is an ideal material to work with for its high strength, low weight, and natural corrosion protection. But working with aluminum alloys requires fabrication techniques that often include welding.

Aluminum assembly requires careful selection of welding techniques due to aluminum’s high thermal conductivity and its oxide formation, which is important for maintaining its corrosion resistance.

Aluminum extrusions support large structures, and often, welded joints in extrusions are under high loads; an inappropriate method can lead to defects like porosity, reduced strength, and HAZ, causing material waste. This makes laser welding vs TIG welding an important decision for aluminum fabrication.

Laser Welding vs TIG Welding: Key Differences at a Glance

| Laser Welding | TIG Welding | |

| Heat Input | Lower heat input, smaller heat-affected zone HAZ | Higher heat input and a naturally larger HAZ |

| سرعة | Fast. It can weld 100”/min if the sections are thin | Slow welding speed |

| Weld penetration | Deep and narrow, around 0.5 inches | Weld penetration ranges from 0.125 to 0.625 inches with a filler |

| مظهر | Smooth and minimal splatter, narrow weld seams | Requires post-processing, like grinders, to remove oxides and irregular surface |

| Material compatibility | Cannot weld or find it difficult to weld reflective aluminum surfaces. Requires pre-heating the aluminum part | Works well with almost all alloys |

| يكلف | High setup cost but low operational cost | Low setup cost but high cost of manual welding |

Table comparing laser welding vs TIG welding.

What Is Laser Welding?

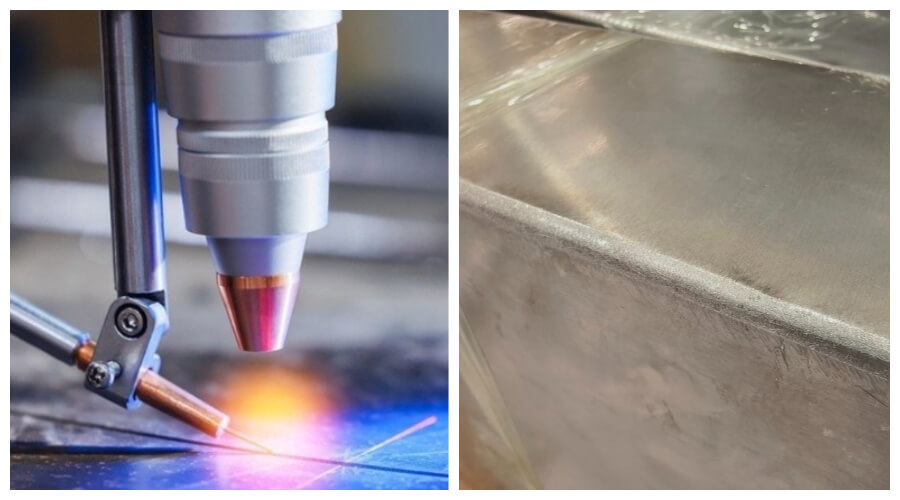

Laser welding works by producing a high-intensity beam of light that melts and fuses aluminum together. The laser welding process is done in the keyhole mode, which is a higher power density mode that creates a cavity (keyhole) surrounded by molten aluminum for a deep and narrow weld. The laser travels along the length of the weld and the molten pool behind solidifies to create a solid metal bond.

Equipped with advanced laser welding machines, we ensure the precision and durability of aluminum extrusion fabrication parts.

What Is TIG Welding?

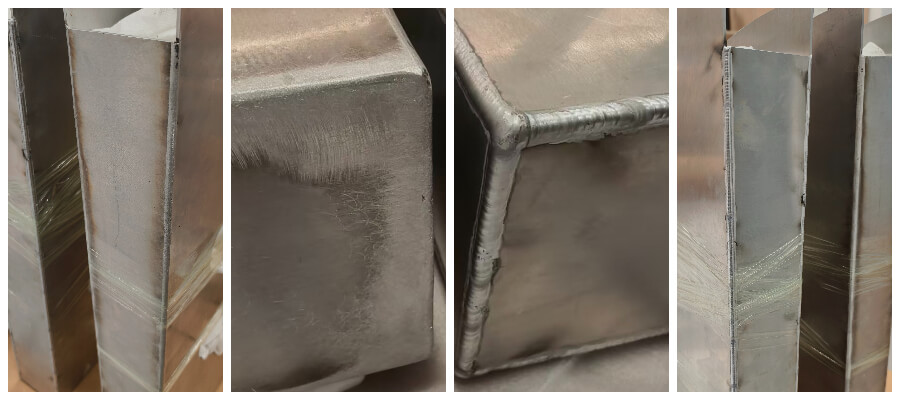

The image shows an aluminium extrusion we produced for a client using TIG welding.

TIG welding is also called Gas Tungsten Arc Welding (GTAW) and uses a non-consumable tungsten electrode to generate an electric arc, which is so intense that it melts the aluminum material on the spot, fusing the base metal for a strong and sturdy bond. Because aluminum oxidizes and the oxidized layer can interfere with the weld quality, TIG welding commonly uses a spray of shielding gas, usually argon, to protect the welding zone. Hence, the name Tungsten Inert Gas (TIG) welding.

Key Differences Between Laser Welding and TIG Welding

Several factors differentiate between laser welding and TIG welding, which are important for aluminum fabrication because they affect aluminum alloy choice and the thickness range of aluminum.

Aluminum Alloy Compatibility With Welding

Aluminum alloys vary in weldability due to their thermal conductivity differences and the reflectivity of their surface. These differences limit the type of alloys for laser welding or TIG welding setups.

Laser welding is ideal for 5000 series alloys because they absorb energy efficiently. Still, high-purity aluminum alloys like 1000 series require adjusting fiber lasers because of their reflectivity and to prevent beam scattering. TIG welding can be used with most common aluminum alloys. AC removes oxides, and the amount of heat can be controlled, making it useful for aluminum alloys that crack under thermal stresses, like 2000 or 7000 series alloys.

سمك المادة

For most think sheet metal aluminum parts, and for aluminum parts with sections smaller than 3 mm, laser welding is fast and efficient with a precise beam that can weld tight joints where filler material is difficult to insert.

TIG welding is ideal for thicker aluminum parts where filler material can fill holes and material gaps. TIG welding aluminum also makes it possible to use complex joint types like T joints and corner joints. TIG welding aluminum requires surface preparation, such as bevel edges, for better penetration of the weld material in thick aluminum parts. Still, it also has a risk of burning through aluminum easily if the current amperage is high or the arc is not controlled.

Distortion

Laser welding has a concentrated beam where energy is focused on a smaller area, and this requires a lower heat input, resulting in a smaller, narrower HAZ and distortion below 0.1 mm on a 1-meter sheet. This makes laser welding ideal for distortion-sensitive applications.

TIG welding inputs higher heat from the arc in the range of 500 – 1500 J/mm, which expands the HAZ, causing warpings of up to 3 mm. TIG welding is not ideal for tolerance-critical parts and, in most cases, requires machining or grinding to match tolerance after welding.

Structural Strength and Fatigue Requirement

For structural parts like aluminum extrusions and aluminum bars, laser welds achieve up to 98% base metal strength and higher fatigue strength because of the smaller heat-affected zone HAZ and distortions. The rapid cooling is also an additional benefit that does not diminish the strength post-welding and makes structural aluminum components sustain cyclic loading.

TIG offers up to 95% strength in most weld applications, but the larger HAZ reduces fatigue life in high-stress applications.

Surface Quality

Most structural parts can be welded on the underside to hide weld marks and weld seams, but aluminum is often used in finished looks in windows, doors, cladding, and extrusions, which can result in an uneven surface. Laser welding produces smooth, spatter-free surfaces with porosity ≤0.1%, requiring minimal post-processing.

TIG yields clean welds, but a larger porosity of 1-3% and a residue that often requires grinding and cleaning. TIG weld marks are easy to spot and generally not preferred for high finish requirements.

Production Volume and Cost Effectiveness

Laser welding is a semi-automated process with machine-controlled parameters and a welding unit. It can weld seams 3 times faster than standard TIG welding for high-volume runs and reduces manual labor in mass production.

TIG is ideal for low-volume, custom work where manual precision and welder skill are required around complex joints. For repetitive welds and identical part fabrication, it is possible to automate TIG welding to achieve production efficiency, but laser welding is still faster.

Laser Welding vs TIG Welding for Aluminum Materials

Thin-Wall Aluminum Extrusions

Thin-wall aluminum extrusions (less than 3 mm) are ideally laser-welded and benefit from the low heat that prevents the aluminum extrusions from warping. Thin-wall extrusions can be welded without filler, and laser welding can ensure penetration in thin walls.

TIG welding thin aluminum extrusions is not ideal because the distortion from the high current arc can produce thick welds or leave a penetration far beyond the welding zone. It requires careful tuning of the amperage, making it a time-consuming process and less ideal for high-precision thin-wall components.

Thick Aluminum Sections

For aluminum extrusions and sections above 3 mm, TIG welding can be used with a filler to produce a weld melt that flows deep into the weld cavity and ensures structural strength for these aluminum components. Laser welding may not penetrate well for thicker aluminum sections, limiting the efficiency, and it is also difficult to set up laser welds for long aluminum extrusions that are joined at angles or in different geometries.

Common Aluminum Alloys and Weldability

| Alloy Series | Typical Examples | General Weldability | TIG Welding Suitability

|

Laser Welding

|

| 1xxx | 1050, 1100, 1350 | ممتاز | ممتاز

|

ممتاز |

| 2xxx | 2024, 2219, 2519 | Poor to Moderate | Poor for most (high cracking risk)

|

Moderate |

| 3xxx | 3003, 3004 | Good to Excellent | ممتاز

|

جيد |

| 5xxx | 5052, 5083, 5086 | ممتاز | Excellent; superior oxide cleaning

|

ممتاز |

| 6xxx | 6061, 6063, 6082 | Good to Moderate | جيد | جيد |

| 7xxx | 7075, 7050, 7039 | فقير | Poor for most | Moderate to Poor |

When to Choose Laser Welding

When choosing between laser welding vs TIG welding in aluminum fabrication, laser welding can be used in aluminum fabrication when you need precision and quicker welding of identical parts and seams.

It processes welding work fast, and the concentrated energy beam results in a narrow heat-affected zone. This means laser welding can be used when dimensional tolerance is important and uniform material properties are required.

You can use laser welding when:

- There are high-volume production runs

- For thin-wall aluminum extrusions and aluminum sheets

- Parts with tight tolerances

- When heat-sensitive alloys are used to minimize the HAZ.

When to Choose TIG Welding

In Laser welding vs TIG welding, TIG welding remains the choice for aluminum projects that require manual flexibility, control, and adaptability to different cross-section and thickness regions on an aluminum part.

TIG welding uses alternating current, which removes the oxide before welding and allows the filler to set with the base metal for a reliable joint assembly.

You can use TIG welding when:

- There is low-volume production and تصنيع الألومنيوم المخصص

- There are thick aluminum sections to weld

- Oxides in the aluminum alloy prevent proper welding

- For manual and complex joint types like T joints

- You need higher weld quality and manual welding parameter control

Final Thoughts from an Aluminum Fabrication Manufacturer

In laser welding vs TIG welding for aluminum fabrication, laser welding offers better speed, precision, and smaller HAZ, which means less distortion. In our years of aluminum fabrication experience, TIG provides control for custom, thick aluminum sections and guarantees weld reliability in complex geometries.

Is laser welding stronger than tig?The choice between these two welding methods is not solely based on strength.The choice between laser welding vs TIG welding depends on the alloy surface reflectivity, fatigue strength requirements, alloy type, thickness, and production speeds.We can custom welding methods to suit your project.

Contact Wellste today! For a complete aluminum fabrication service and reviewing aluminum extrusion options for your custom projects.